Method for extracting DHA crude oil

An extraction method and crude oil technology are applied in the field of producing mixed oils and fats containing docosahexaenoic acid, and can solve the problems of high deodorization temperature, environmental pollution, easy generation of trans fatty acids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

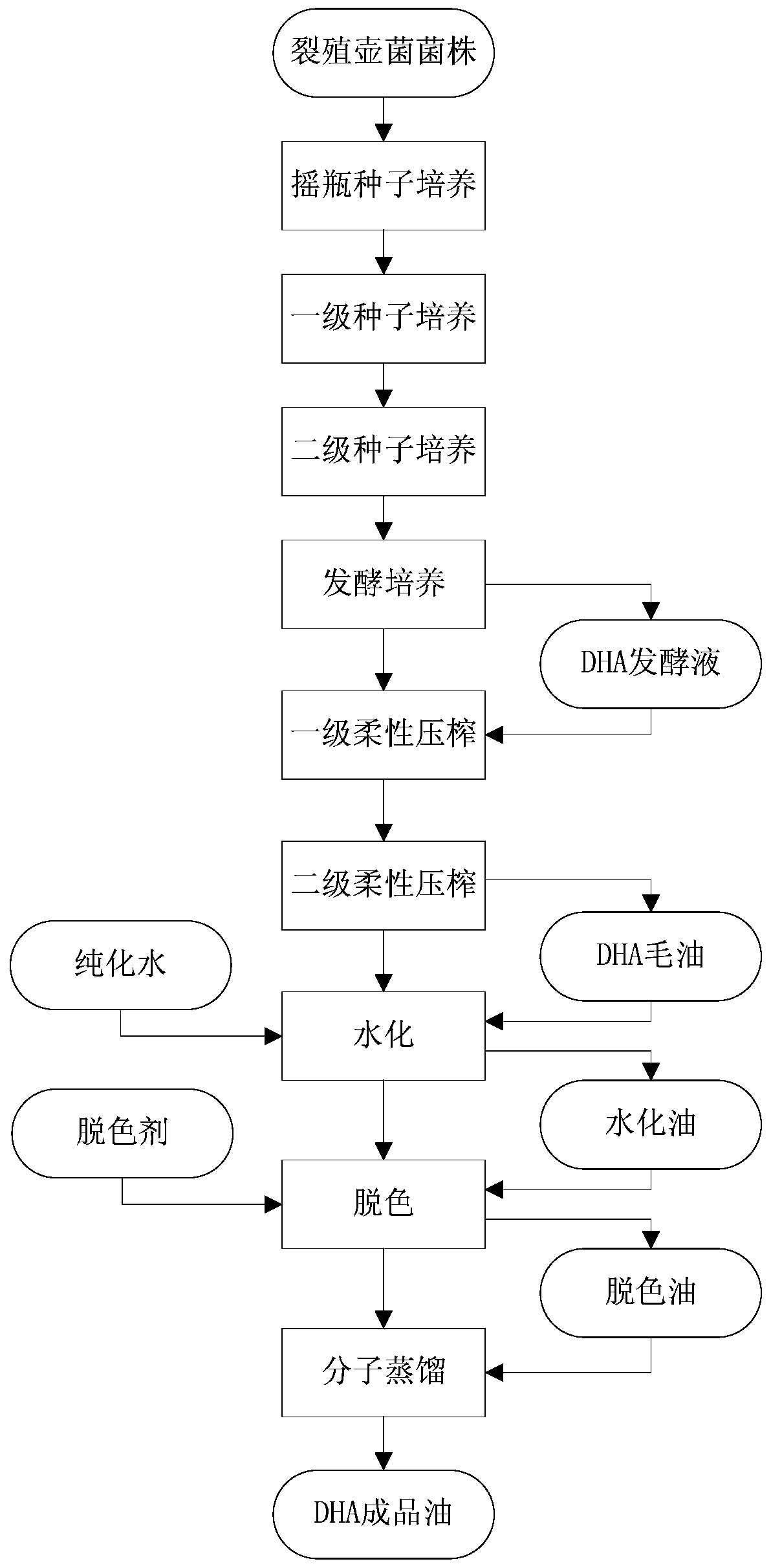

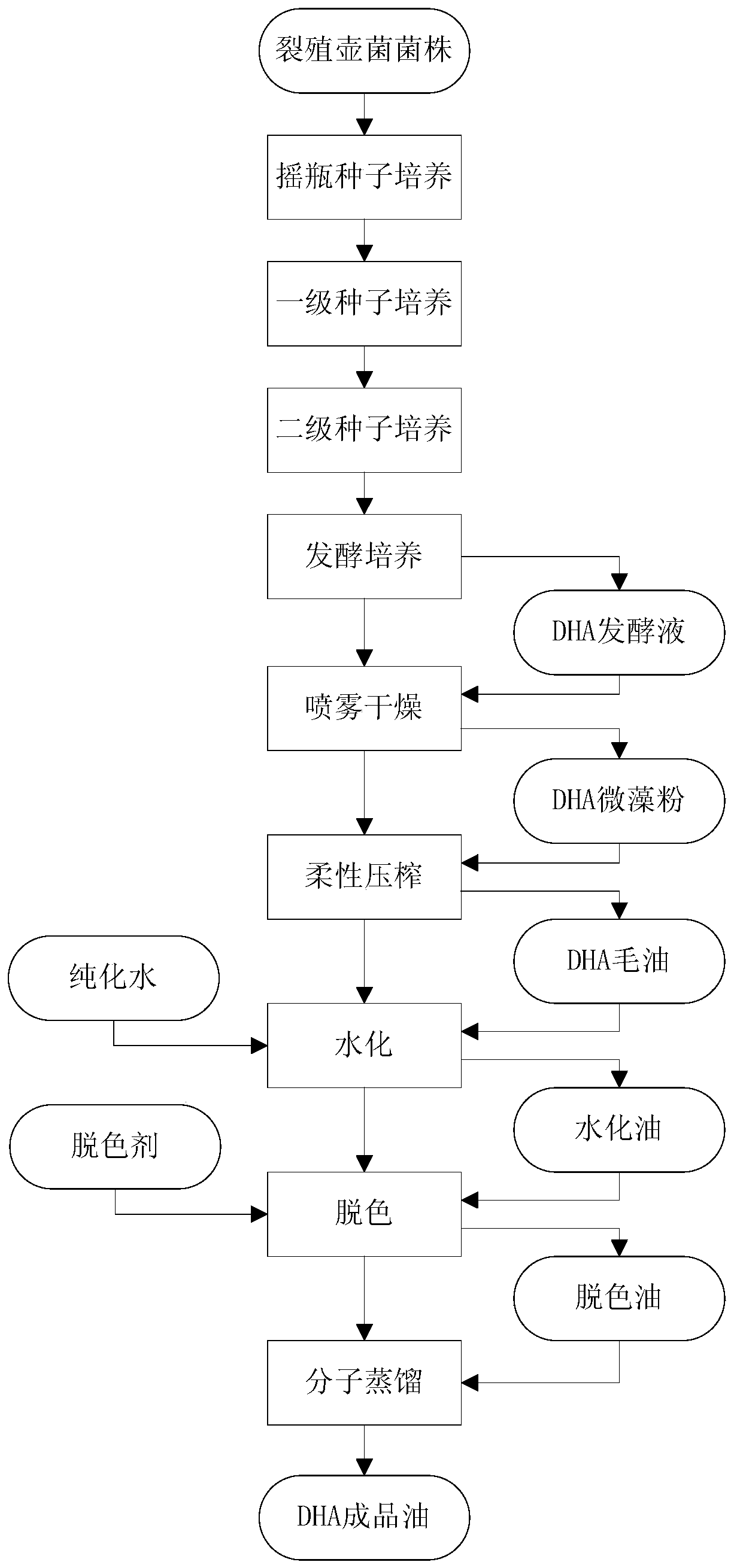

Method used

Image

Examples

Embodiment 1

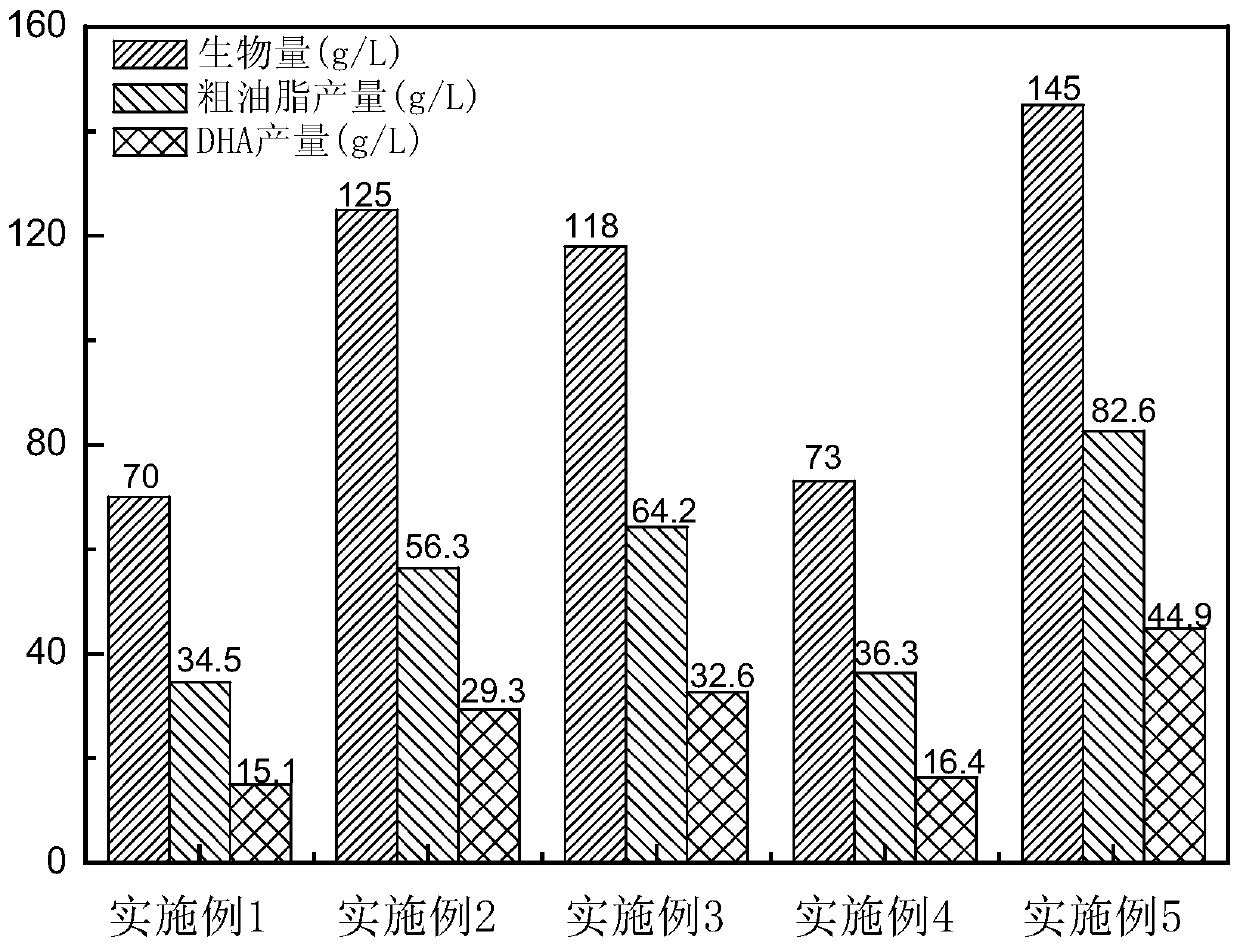

[0126] Embodiment 1 is the original culture method (does not adopt dissolved oxygen control strategy, nitrogen source control strategy and sub-tank culture strategy); embodiment 2 adopts dissolved oxygen control strategy; embodiment 3 adopts nitrogen source control strategy; embodiment 4 is The strategy of sub-tank cultivation was adopted; in Examples 5-13, the strategy of regulating dissolved oxygen, the strategy of nitrogen source regulation and the strategy of sub-tank cultivation were adopted at the same time.

[0127] In the following examples 1-13, unless otherwise specified, the formula of the seed medium used is: glucose 3%, peptone 1%, yeast powder 0.5%, sea crystal 2%, pH natural (the rest is water). The formula of the fermentation medium is: glucose 12%, peptone 1%, yeast powder 0.5%, sea crystal 2% (the rest is water).

[0128] Example 1: The original culture method (do not adopt dissolved oxygen control strategy, nitrogen source control strategy and sub-tank cul...

Embodiment 2

[0137] Example 2: Dissolved oxygen regulation strategy is used to control 100m 3 Effects of Fermentation Tank Fermentation on Production of DHA

[0138] The slant-preserved strain of Schizochytrium sp. CGMCC No. 6843 was inserted into a 2L shake flask containing 400 mL of medium, and cultured at a temperature of 25° C. at a rotation speed of 200 rpm for 24 hours to complete the activation culture of the strain. According to the inoculation amount of 0.4%, the shake flask seed solution was connected to the primary seed tank equipped with the sterilized medium, cultivated at a temperature of 28°C, a ventilation rate of 1vvm, a tank pressure of 0.02MPa, and a stirring speed of 50rpm for 30h to complete the primary stage Seed expansion cultivation. According to the inoculation amount of 3%, the seed liquid of the first-level seed tank was connected to the second-level seed tank equipped with the sterilized medium, and the culture temperature was 28 ° C, the ventilation rate was...

Embodiment 3

[0143] Embodiment 3: Using nitrogen source control strategy to 100m 3 Effects of Fermentation Tank Fermentation on Production of DHA

[0144] The slant-preserved strain of Schizochytrium sp. CGMCC No. 6843 was inserted into a 2L shake flask containing 400 mL of medium, and cultured at a temperature of 25° C. at a rotation speed of 200 rpm for 24 hours to complete the activation culture of the strain. According to the inoculation amount of 0.4%, the shake flask seed solution was connected to the primary seed tank equipped with the sterilized medium, the cultivation temperature was 28°C, the ventilation rate was 1vvm, the tank pressure was 0.02MPa, and the stirring speed was 50rpm and cultivated for 30h to complete the primary stage Seed expansion cultivation. According to the inoculation amount of 3%, the seed liquid of the first-level seed tank was connected to the second-level seed tank equipped with the sterilized medium, and the culture temperature was 28 ° C, the ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com