Carbon nanotube doped ionic liquid modified butyl rubber elastomer and preparation method

A carbon nanotube and butyl rubber technology is applied in the field of preparation of ionic liquid-modified butyl rubber elastomers, which can solve problems such as the inability to achieve effective dispersion of carbon nanotubes and hinder the research and development of rubber composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

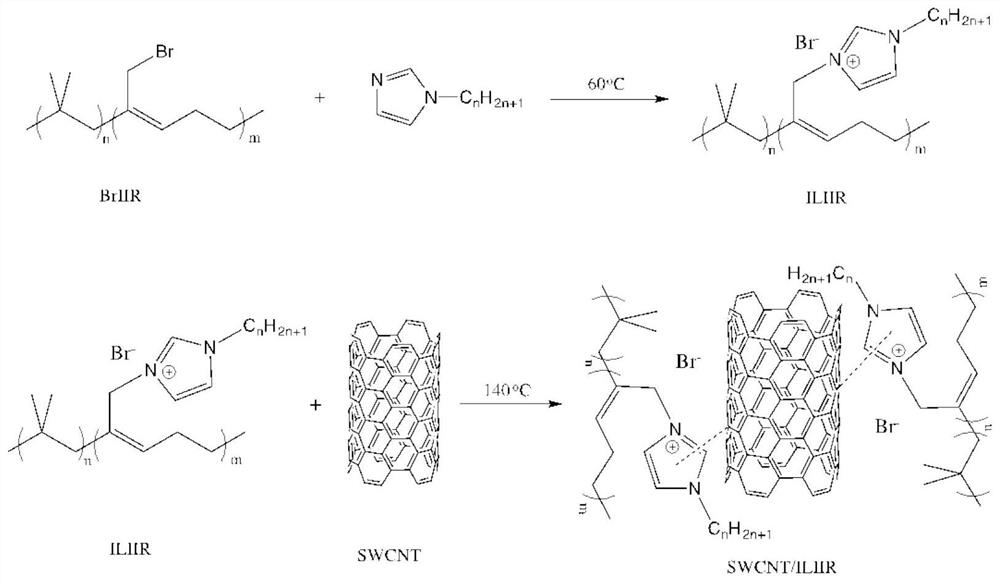

[0032] refer to figure 2 Shown, the present invention also provides the preparation method of the ionic liquid modified butyl rubber elastomer of described carbon nanotube doping, it comprises the following steps:

[0033] Step (1) Adding bromobutyl rubber and imidazole molecular additives to the rubber mixer, the molar ratio of addition is: imidazole: bromine group = 1.5:1.

[0034] Step (2) Add carbon nanotube powder to the mixture in the above step (1), and the mass ratio is: mixture:CNT=100:2-5.

[0035] Step (3) For the mixture of the above step (2), first heat up to 60°C, stir and mix at 100 rpm for 1 hour, then heat up to 140°C, and solidify and mold under a pressure of 150kN for 2 hours to obtain a sheet Composite rubber elastomer sheet.

Embodiment 1

[0037] First weigh the brominated butyl rubber, add 1.5 times 1-methylimidazole according to the molar ratio of the relative bromine content, and then add 2wt% carbon nanotube powder in the rubber mixer at 60 ° C, 100 rpm, stirring and mixing for 1 hours, then heated up to 140°C, and cured under a pressure of 150kN for 2 hours to obtain a sheet-like composite rubber elastomer sheet.

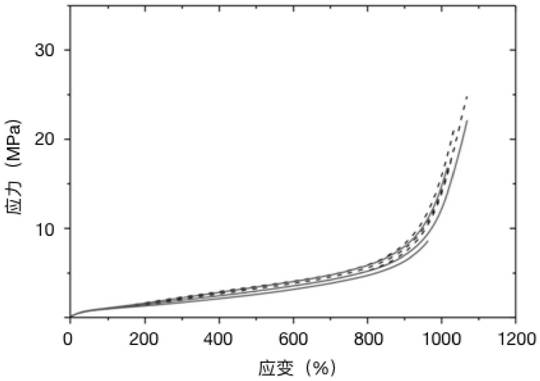

[0038] The test results of the composite material made in this example: the tensile strength is 21.9MPa, the elongation at break is 10.6 times, the dielectric constant is 21 and the conductivity is 1.1×10 -5 S / cm.

Embodiment 2

[0040] First weigh the brominated butyl rubber, add 1.5 times 1-ethylimidazole according to the molar ratio of the relative bromine content, and then add 2.5wt% carbon nanotube powder in the rubber mixer at 60°C and 100 rpm to stir and mix 1 hour, then heated up to 140°C, and cured and molded under a pressure of 150kN for 2 hours to obtain a sheet-shaped composite rubber elastomer sheet.

[0041] The test results of the composite material obtained in this example: the tensile strength is 17.8MPa, the elongation at break is 10.1 times, the dielectric constant is 23 and the electrical conductivity is 1.5×10 -5 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com