Formaldehyde-free preimpregnation glue and synthetic process thereof

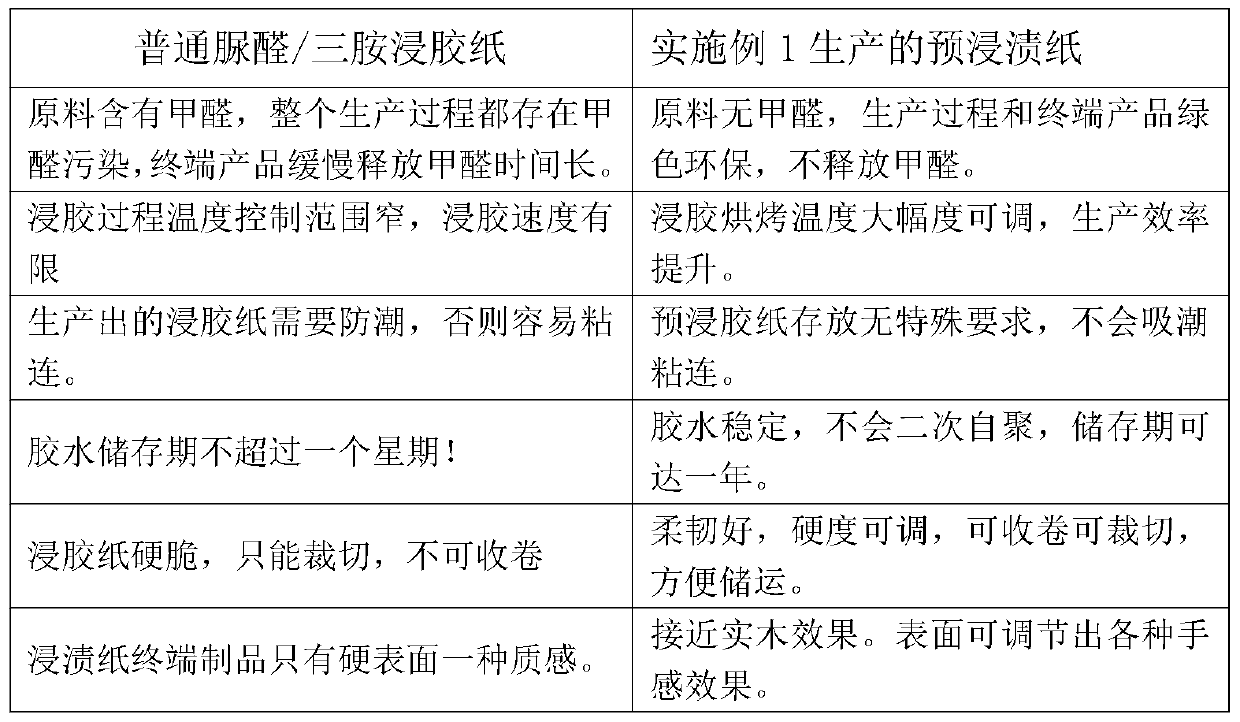

A synthesis process and prepreg technology, which is applied in the field of aldehyde-free prepreg and its synthesis process, can solve the problems of decolorization, large impregnation amount, decreased printing performance, etc., and achieve the effect of stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of formaldehyde-free prepreg, by mass parts, comprises following raw material:

[0042] 0.713 g of ammonium bicarbonate;

[0043] 4.65g concentration is 25% ammonia water;

[0044] 2.558g ammonium persulfate;

[0045] 0.775g concentration is 70% tert-butyl hydroperoxide;

[0046] 4.2g emulsifier CO436;

[0047] 0.775g concentration is 95% sodium formaldehyde sulfoxylate;

[0048] 0.9g defoamer;

[0049] 1.24g surfactant OT-75;

[0050] 5.6g acrylic acid;

[0051] 12.5g methyl acrylate;

[0052] 200g styrene;

[0053] 340g butyl acrylate;

[0054] Some deionized water.

[0055] A kind of synthesis process of a kind of formaldehyde-free impregnated glue described in claim 1, in parts by mass, comprises the steps:

[0056] step 1):

[0057] ① Take 0.713g of ammonium bicarbonate and dissolve it in 3.1g of water to make an aqueous solution of ammonium bicarbonate;

[0058] ② Dissolve 4.65g of ammonia water with a concentration of 25% in 4.65g of water to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com