A kind of diethanol monoisopropanolamine continuous production process

A monoisopropanolamine, production process technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problem of inability to ensure continuous and stable production of products, high labor intensity of operators, and poor product quality. Control and other issues, to achieve the effects of less axial back mixing, reduced labor intensity, and reduced side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

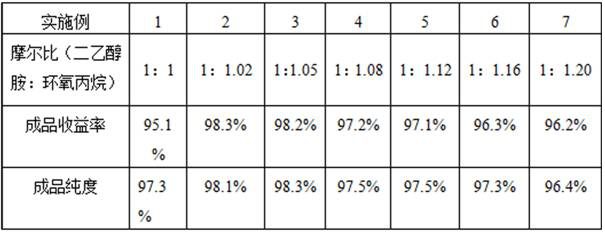

Embodiment 1-7

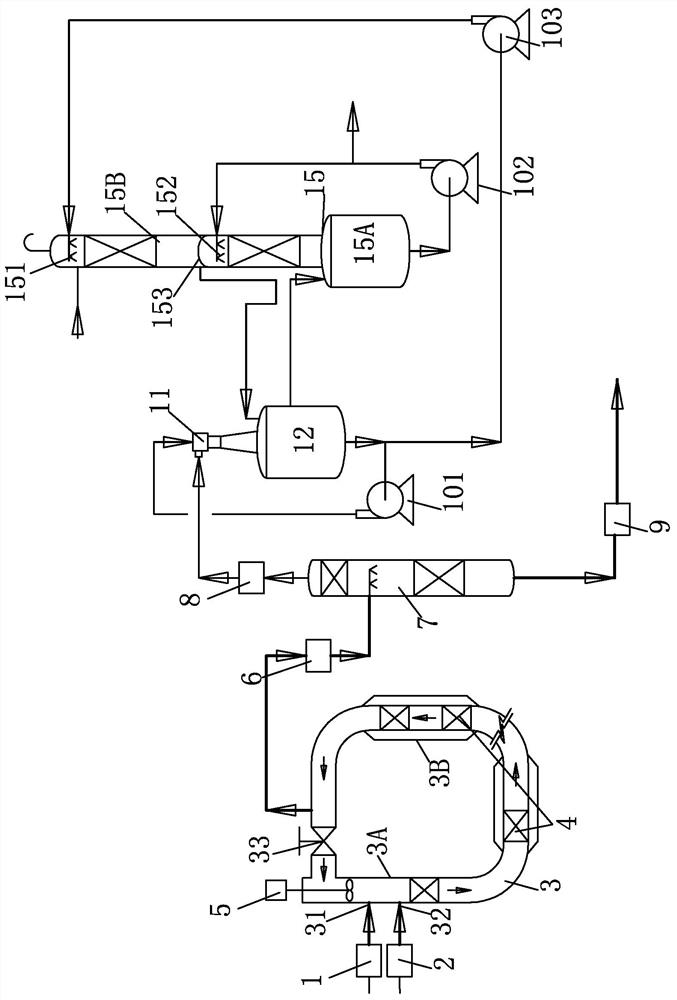

[0033] The diethanolamine is preheated to 70-80°C before entering the reactor, and the diethanolamine is continuously metered by the mass flow meter 1, and the propylene oxide is continuously metered by the mass flow meter 2, and then flows into the jacketed loop reactor 3, wherein the diethanolamine and epoxy The molar ratio of propane is 1:1.0-1.2, through the internal parts such as static mixer 4 and axial flow propeller 5 in the jacketed loop reactor 3, the materials can be fully mixed, flowed and reacted, and the reaction temperature is controlled to be 75 ℃, the back section is 95℃, and the pressure is 1.8-2MPa. The reaction materials are circulated by the axial flow propeller 5 in the loop reactor, part of the reaction materials flow into the vacuum flash packing tower 7 after being measured by the mass flow meter 6, and the liquid phase discharge at the bottom of the vacuum flash packing tower 7 is Diethanolamine monoisopropanolamine product, go to product intermediate...

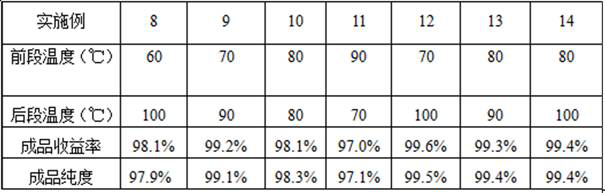

Embodiment 8-14

[0040]The diethanolamine is preheated to 70-80°C before entering the reactor, and the diethanolamine is continuously metered by the mass flow meter 1, and the propylene oxide is continuously metered by the mass flow meter 2, and then flows into the jacketed loop reactor 3, wherein the diethanolamine and epoxy The molar ratio of propane is 1:1.02, through the static mixer 4, axial flow propeller 5 and other internal parts in the jacketed loop reactor 3, the materials can be fully mixed, flowed and reacted, and the reaction temperature is controlled at 60-100°C , where the front section is 70-80°C, and the back section is 90-100°C. Pressure 1.8-2MPa. The reaction materials are circulated by the axial flow propeller 5 in the loop reactor, part of the reaction materials flow into the vacuum flash packing tower 7 after being measured by the mass flow meter 6, and the liquid phase discharge at the bottom of the vacuum flash packing tower 7 is Diethanolamine monoisopropanolamine pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com