A kind of indium zinc sulfide/black phosphorus quantum dot and its preparation method and application

A technology of sulfur indium zinc and quantum dots, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of fast recombination of photogenerated electrons and holes, affecting the efficiency of photocatalytic water splitting, etc., to achieve Improved electron-hole separation efficiency, excellent photocatalytic water splitting performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

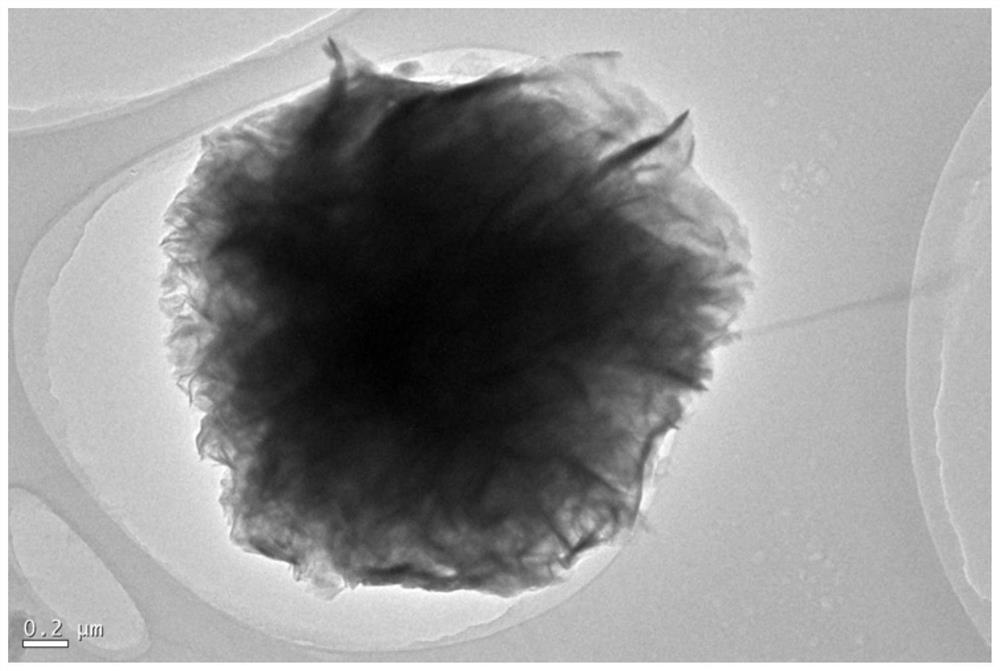

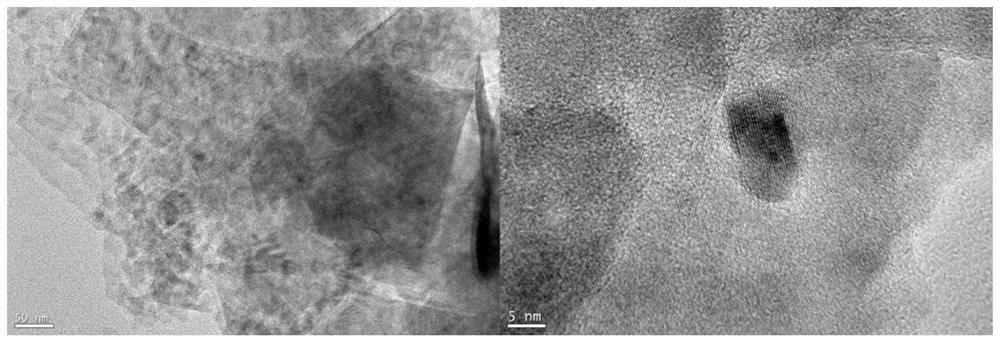

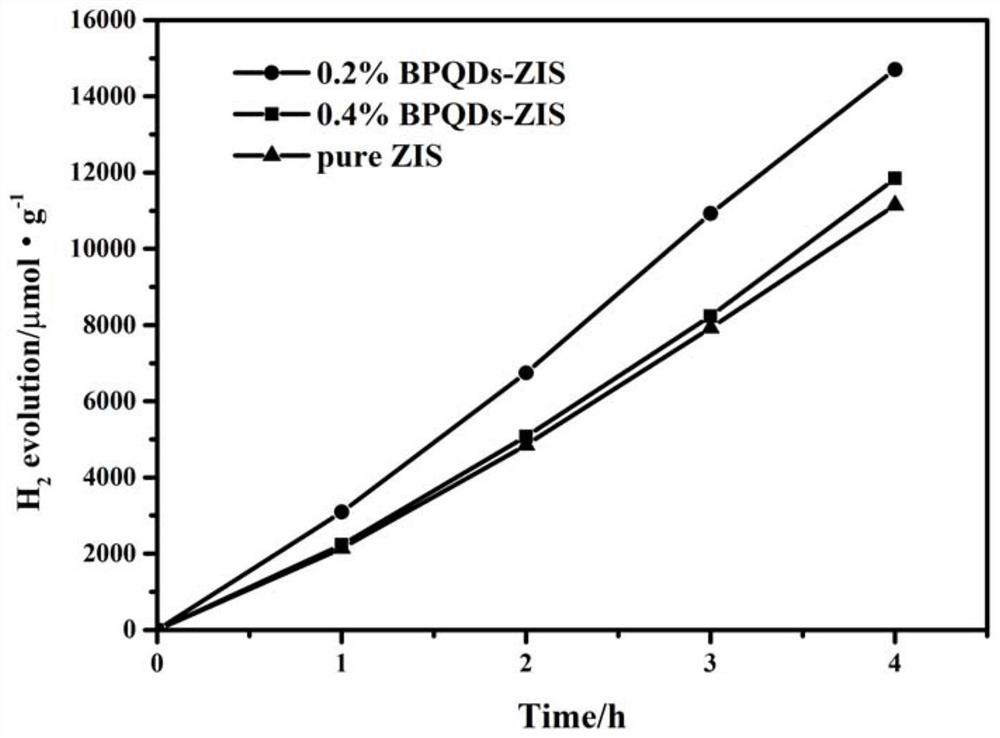

[0035] A sulfur indium zinc / black phosphorus quantum dot photocatalyst for photocatalytic water splitting, the preparation method of which is as follows.

[0036] 1. Preparation of sulfur indium zinc: 1.0mmol zinc chloride, 2.0mmol indium chloride and 6.0mmol thioacetamide (TAA) were dissolved in 80mL deionized water, and added to a 150mL polytetrafluoroethylene reactor at 80°C for water Heat for 12 hours, cool to room temperature, centrifuge, wash and dry to obtain sulfur indium zinc powder;

[0037] 2. Compound sulfur indium zinc and black phosphorus quantum dots: disperse 0.2 g of sulfur indium zinc obtained in step 1 in 20 mL of DMF, add 2 mL of 0.2 mg / mL black phosphorus quantum dot DMF dispersion, and stir overnight; black phosphorus The DMF dispersion of quantum dots was prepared by the following method: 10 mg of black phosphorus crystals were added to 10 mL of DMF, and a cell pulverizer was used to sonicate for 6 hours in an ice bath to obtain a dispersion; the dispers...

Embodiment 2

[0041] A sulfur indium zinc / black phosphorus quantum dot photocatalyst for photocatalytic water splitting, the preparation method of which is as follows.

[0042] 1. Preparation of sulfur indium zinc: 1.0mmol zinc chloride, 2.0mmol indium chloride and 6.0mmol thioacetamide (TAA) were dissolved in 80mL deionized water, and added to a 150mL polytetrafluoroethylene reactor at 80°C for water Heat for 14 hours, cool to room temperature, centrifuge, wash and dry to obtain sulfur indium zinc powder.

[0043] 2. Compound sulfur indium zinc and black phosphorus quantum dots: disperse 0.2g sulfur indium zinc obtained in step 1 in 20mL DMF, add 2mL0.2mg / mL black phosphorus quantum dot DMF dispersion, and stir overnight;

[0044] 3. Centrifuge the solution obtained in step 2 to obtain the precipitate, wash it several times with ethanol, and then dry it in a vacuum oven at 40°C overnight;

[0045] 4. Grinding the solid obtained in step 3 to obtain sample powder.

Embodiment 3

[0047] A sulfur indium zinc / black phosphorus quantum dot photocatalyst for photocatalytic water splitting, the preparation method of which is as follows.

[0048] 1. Preparation of sulfur indium zinc: 1.0mmol zinc chloride, 2.0mmol indium chloride and 6.0mmol thioacetamide (TAA) were dissolved in 80mL deionized water, and added to a 150mL polytetrafluoroethylene reactor at 100°C for water Heat for 12 hours, cool to room temperature, centrifuge, wash and dry to obtain sulfur indium zinc powder;

[0049] 2. Compound sulfur indium zinc and black phosphorus quantum dots: disperse 0.2g sulfur indium zinc obtained in step 1 in 20mL DMF, add 2mL0.2mg / mL black phosphorus quantum dot DMF dispersion, and stir overnight;

[0050] 3. Centrifuge the solution obtained in step 2 to obtain the precipitate, wash it several times with ethanol, and then dry it in a vacuum oven at 40°C overnight;

[0051] 4. Grinding the solid obtained in step 3 to obtain sample powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com