Zinc oxide piezoresistive element with solder alloy layer electrode and preparation method thereof

A varistor and zinc oxide technology, which is applied in varistors, overvoltage protection resistors, resistance manufacturing, etc., can solve the problems of inapplicable preparation, increase of preparation cost, complicated process, etc., to increase mechanical bonding and ohmic The contact area, the elimination of electrode sintering and spraying processes, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

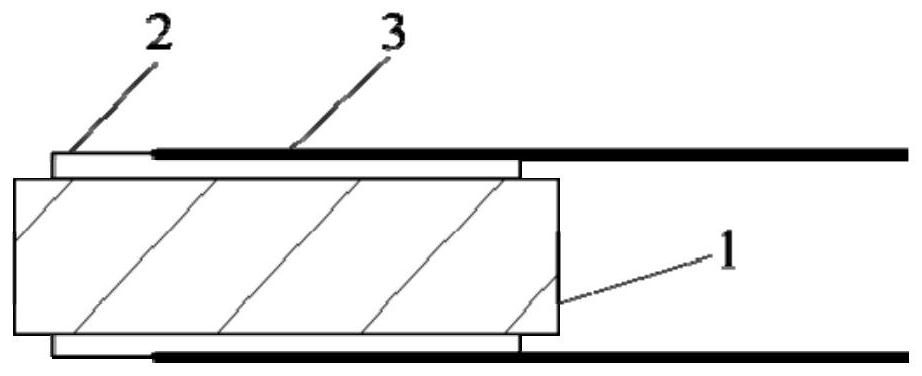

[0049] In this example, two active solders with different Ag contents were used to prepare samples for comparison, and their specific components are shown in Table 1. Single-layer solder alloy layer electrodes were prepared on the surface of 14E-type circular zinc oxide ceramic sheets by hot head scraping coating brazing, and then combined with the flame heating brazing process to prepare single-layer solder alloy layer electrodes. Zinc varistor element. The structural representation of the zinc oxide varistor element of the prepared single-layer solder alloy layer electrode is as follows figure 1 As shown, it specifically includes a zinc oxide ceramic sheet 1, a solder alloy layer electrode 2 and an electrode lead 3; the circular zinc oxide ceramic sheet 1 is provided with a solder alloy layer electrode 2, the solder alloy layer electrode 2 and the electrode lead 3 to form a connection. For the zinc oxide piezoresistive elements of the two solder alloy layer electrodes in t...

Embodiment 2

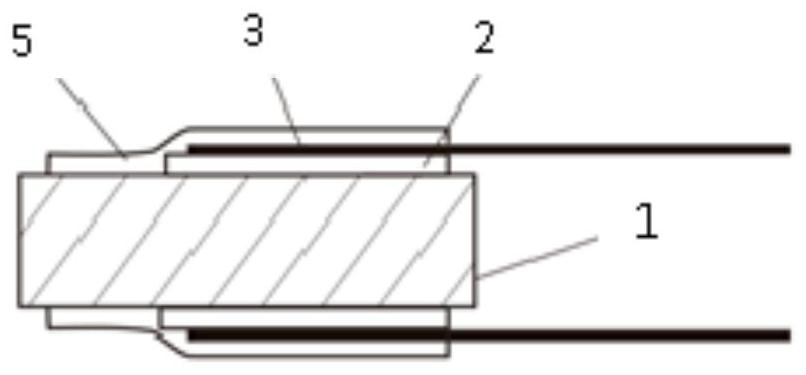

[0068] This embodiment uses Sn0.8Ag2Ti0.5Zn (0.1Ce) active solder, and its composition is shown in Table 3. The solder alloy layer electrode is first prepared on the surface of the 20E circular zinc oxide ceramic sheet by ultrasonic assisted active solder; combined with the hot air heating brazing process to complete the interconnection between the lead wire / solder alloy layer electrode / zinc oxide ceramic sheet ; Afterwards, a second layer of sprayed aluminum electrode layer is prepared on the surface of the solder alloy layer electrode and the electrode lead wire by using a thermal spraying process. The schematic diagram of the cross-sectional structure of the final prepared double-layer electrode zinc oxide varistor element is shown in image 3 As shown, it specifically includes a zinc oxide ceramic sheet 1, a solder alloy layer electrode 2, an electrode lead 3 and a sprayed aluminum electrode 5; The solder alloy layer electrode 2 is connected with the electrode lead 3; aft...

Embodiment 3

[0088] In this embodiment, Sn1.5Ag3Ti0.5Zn active solder is used, and its composition is shown in Table 5. The active solder is assisted by ultrasonic waves, and a solder alloy layer electrode is prepared on the surface of the 34S square zinc oxide ceramic sheet; combined with the flame heating brazing process, the interconnection between the lead wire / solder alloy layer electrode / zinc oxide ceramic sheet is completed ; After that, a second layer of sprayed aluminum electrode layer is prepared on the surface of the solder alloy layer electrode and the electrode lead wire by using a thermal spraying process. The schematic diagram of the cross-sectional structure of the final prepared double-layer electrode zinc oxide varistor element can still refer to the schematic diagram image 3 , specifically including a zinc oxide ceramic sheet 1, a solder alloy layer electrode 2, an electrode lead 3 and a sprayed aluminum electrode 5; the zinc oxide ceramic sheet 1 is provided with a sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com