A kind of preparation method of copper-graphite-polytetrafluoroethylene composite material

A technology of polytetrafluoroethylene and composite materials, which is applied in the field of powder metallurgy, can solve problems such as limited application range, shallow penetration depth, and poor penetration resistance, and achieve the effects of reducing friction coefficient, increasing service life, and increasing impregnation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention provides a kind of preparation method of copper-graphite-polytetrafluoroethylene composite material, comprises the following steps:

[0037] (1) be that the purity of 65% is 99.9%, the particle size is less than 300 mesh graphite powder, the volume fraction 30% purity is 99.5%, the particle size is less than 400 mesh electrolytic copper powder, the forming agent (stearin) of volume fraction 5%. Zinc acid) mixed evenly, and then pressed, sintered, and cut to prepare a 20mm×20mm×20mm (length×width×height) copper graphite matrix (Cu-C), figure 1 It is the SEM image of the copper-graphite matrix;

[0038] (2) Put the copper-graphite matrix in acetone and absolute ethanol in turn for 15 minutes and place it in a vacuum drying oven at 80° C. for 0.5 hours, and cool it down to room temperature naturally to obtain a pretreated copper-graphite matrix;

[0039] (3) Put the pretreated copper-graphite matrix into the reaction kettle, add polytetrafluoroethylene dispe...

Embodiment 2

[0044] The invention provides a kind of preparation method of copper-graphite-polytetrafluoroethylene composite material, comprises the following steps:

[0045] (1) be that the purity of 55% by volume fraction is 99.9%, particle size is less than 300 purpose graphite powder, the purity of volume fraction 41% is 99.5%, the particle size is less than 400 purpose electrolytic copper powder, the forming agent (stearin) of volume fraction 4% Zinc acid) mixed uniformly, then pressed, sintered and cut to prepare a 20mm×20mm×20mm (length×width×height) copper-graphite matrix;

[0046] (2) Put the copper-graphite matrix in acetone and absolute ethanol in turn for 15 minutes and place it in a vacuum drying oven at 60° C. for 4 hours, and cool it down to room temperature naturally to obtain a pretreated copper-graphite matrix;

[0047] (3) Put the pretreated copper graphite matrix into the reaction kettle, add polytetrafluoroethylene dispersion, control the liquid level to be 10-20mm highe...

Embodiment 3

[0051] The invention provides a kind of preparation method of copper-graphite-polytetrafluoroethylene composite material, comprises the following steps:

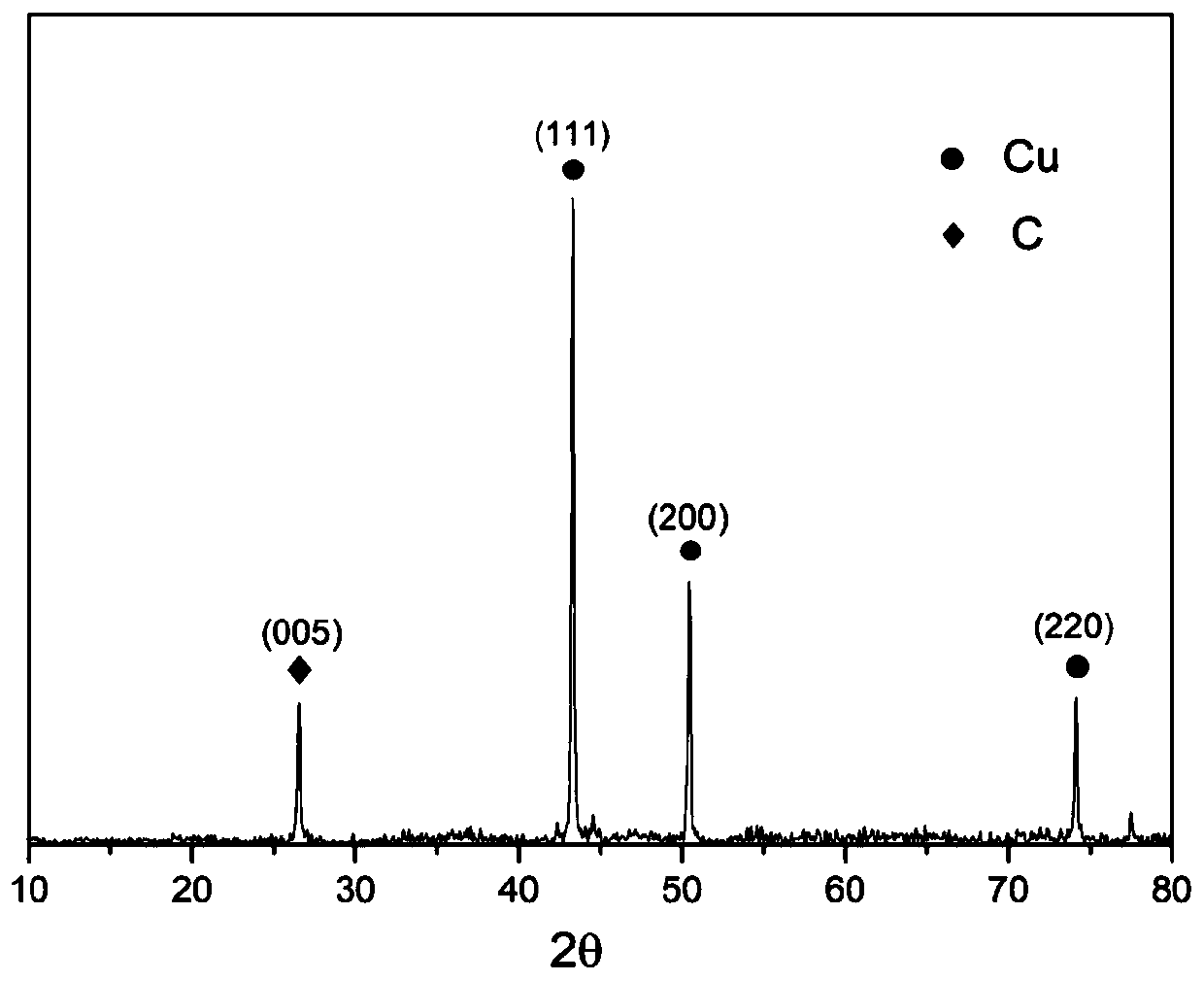

[0052] (1) be that the purity of 56% is 99.9%, particle size is less than 300 mesh graphite powder, the purity of volume fraction 40% is 99.5%, the particle size is less than 400 mesh electrolytic copper powder, the forming agent (stearin) of volume fraction 4% acid zinc) mixed evenly, and then through pressing, sintering, and cutting to prepare a 20mm×20mm×20mm (length×width×height) copper-graphite substrate, image 3 It is the XRD pattern of the copper-graphite matrix. It can be seen from the figure that the copper-graphite matrix only contains Cu phase and C phase, without other impurity phases, and the crystallinity is good;

[0053] (2) Put the copper-graphite substrate in acetone and absolute ethanol in turn for 15 minutes and place it in a vacuum drying oven at 70° C. for 1 hour, and cool it down to room temperature n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com