Li-Ti3C2-rGO composite thin film material and preparation method thereof

A composite film and film technology, applied in electrode manufacturing, electrical components, battery electrodes, etc., can solve the problems of poor mechanical properties, long time required, difficult porous films, etc., to achieve good flexibility, mechanical strength, and improved use safety. , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Prepare GO dispersion and Ti 3 C 2 Dispersion solution, the concentration is 1-4mg / mL, the two are mixed according to a certain volume ratio, stirred and then ultrasonicated for 10-60min;

[0037] Step 2: Add the solution obtained in Step 1 into a vacuum filter in batches, and filter for 12 to 24 hours;

[0038] Step 3: The Ti obtained by suction filtration in Step 2 3 C 2 -GO film, after natural air-drying for 24 hours, was torn off from the filter membrane to obtain Ti 3 C 2 -GO film. Ti 3 C 2 -GO thin film is exposed to a hot stage at 200-400°C to make the Ti 3 C 2 -GO films become porous Ti 3 C 2 -rGO;

[0039] Step 4: the porous Ti in step 3 3 C 2 -rGO thin film, contact with molten metal lithium at 200-400°C in argon glove phase to obtain Li-Ti 3 C 2 - rGO composite thin film material.

Embodiment 2

[0041] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that Ti 3 C 2 Prepare a 2 mg / ml solution with GO, then mix it according to the volume ratio of 1:1 and stir for 30 minutes; the suction filtration time in step 2 is 20 h; the temperature in step 3 and step 4 is 350°C.

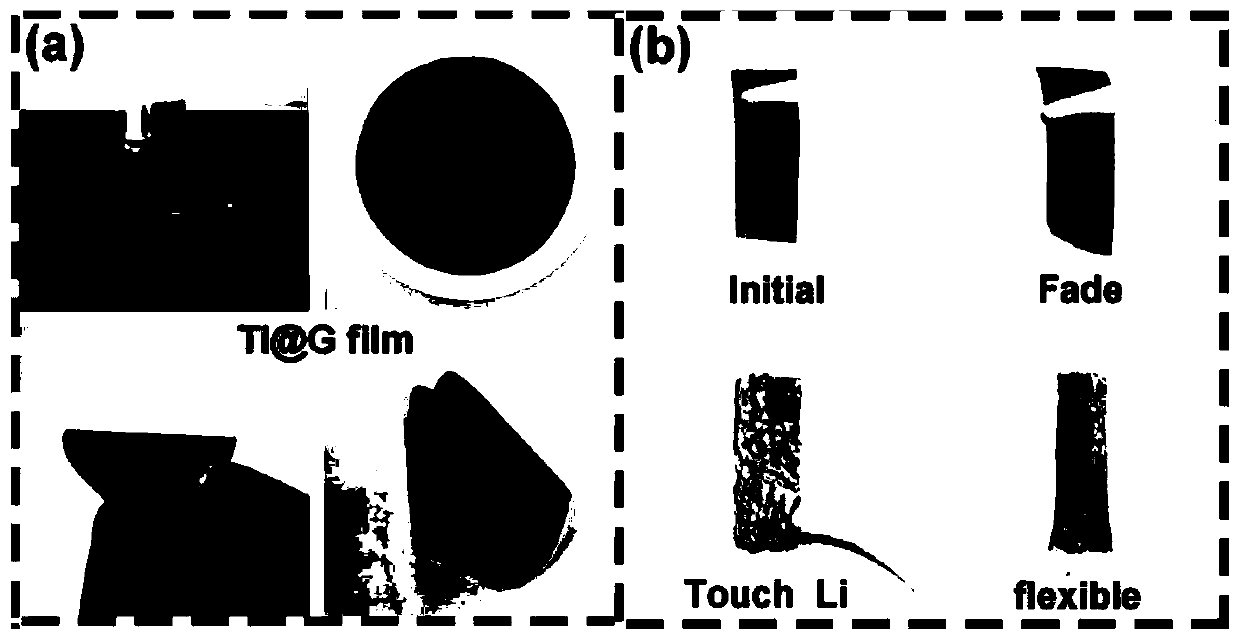

[0042] figure 1 a is the prepared Ti 3 C 2 -GO films, figure 1 b is the prepared Ti 3 C 2 -rGO film and Li-Ti 3 C 2 -rGO film.

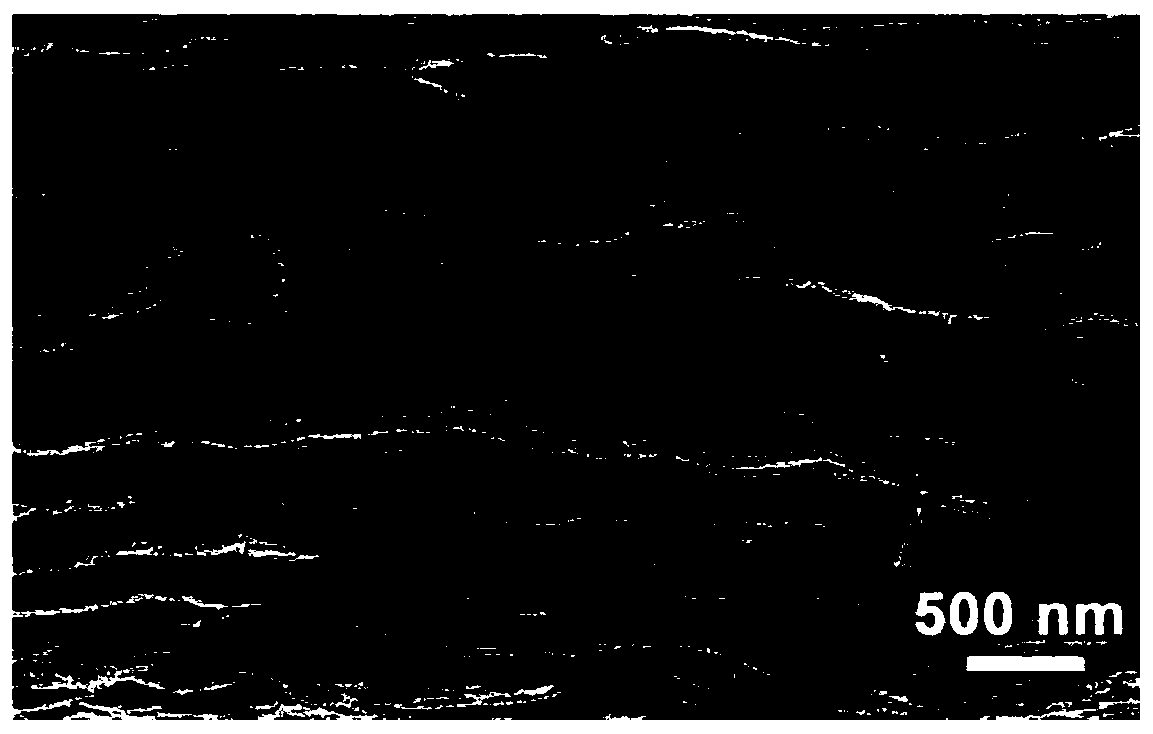

[0043] figure 2 For the prepared Ti 3 C 2 - Microstructure of GO thin films, showing a tight packing structure.

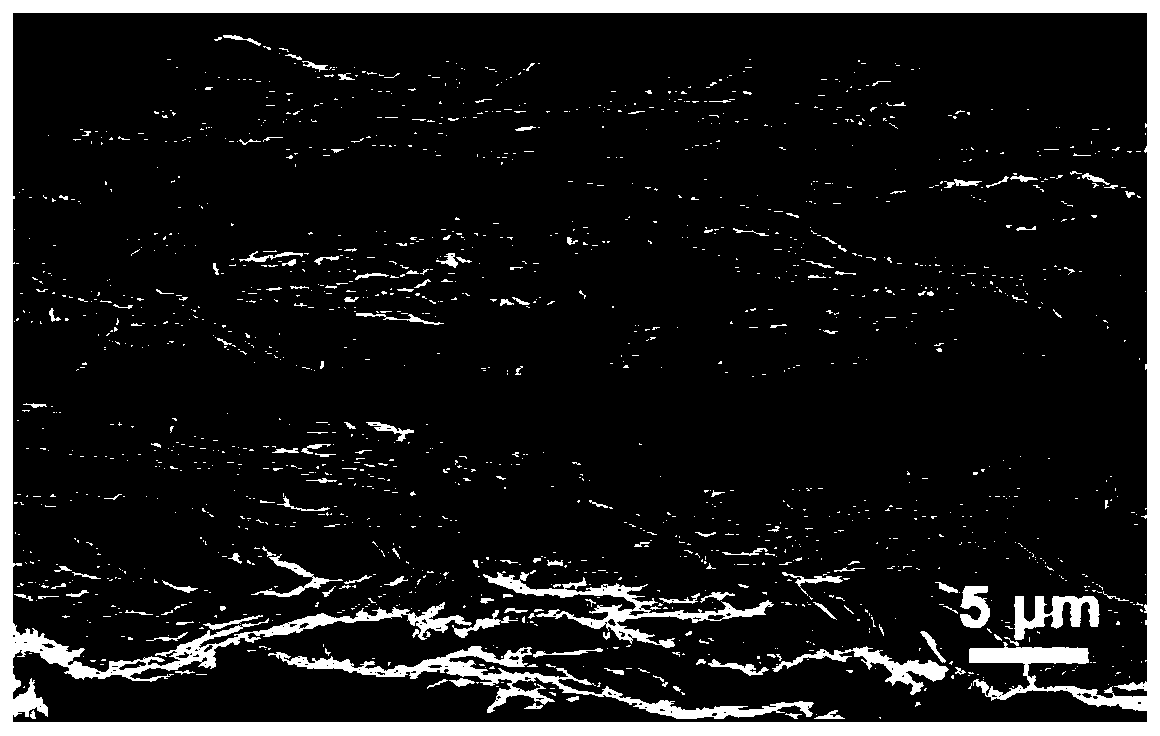

[0044] image 3 For the prepared Ti 3 C 2 - Microstructure of the rGO film, showing a porous structure.

[0045] Figure 4 For the prepared Li-Ti 3 C 2 - Microstructure of rGO thin film, metal lithium is successfully stored between each layer.

[0046] Figure 5 Li-Ti prepared for this example 3 C 2 - Stability comparison of rGO films with current industrially produced pure metal lithium flakes. A...

Embodiment 3

[0049] The steps of this embodiment are basically the same as those of Embodiment 2, except that the Ti in step 1 3 C 2 The ratio with GO is adjusted to 2:1 (Ti 3 C 2 :GO).

[0050] Li-Ti prepared in this example 3 C 2 - The rGO thin film can be stably cycled for more than 1200h at a current density of 1mA / g (1mAh / g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com