Preparation method of high-fine-grain atomized copper alloy powder

A technology of atomizing copper and alloy powder, applied in the field of new materials, can solve the problems of atomized copper powder and its material microstructure, no research reports, no authoritative theory, etc., and achieve the best particle size distribution range , high subdivision rate, and the effect of preventing irregular growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

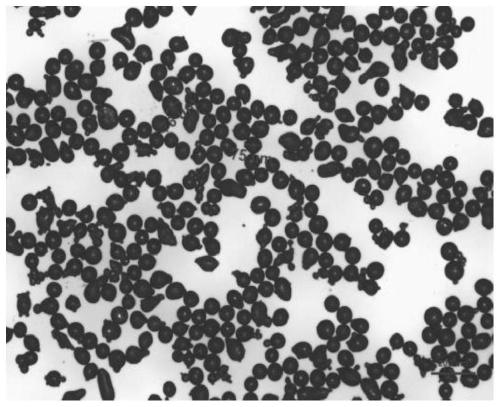

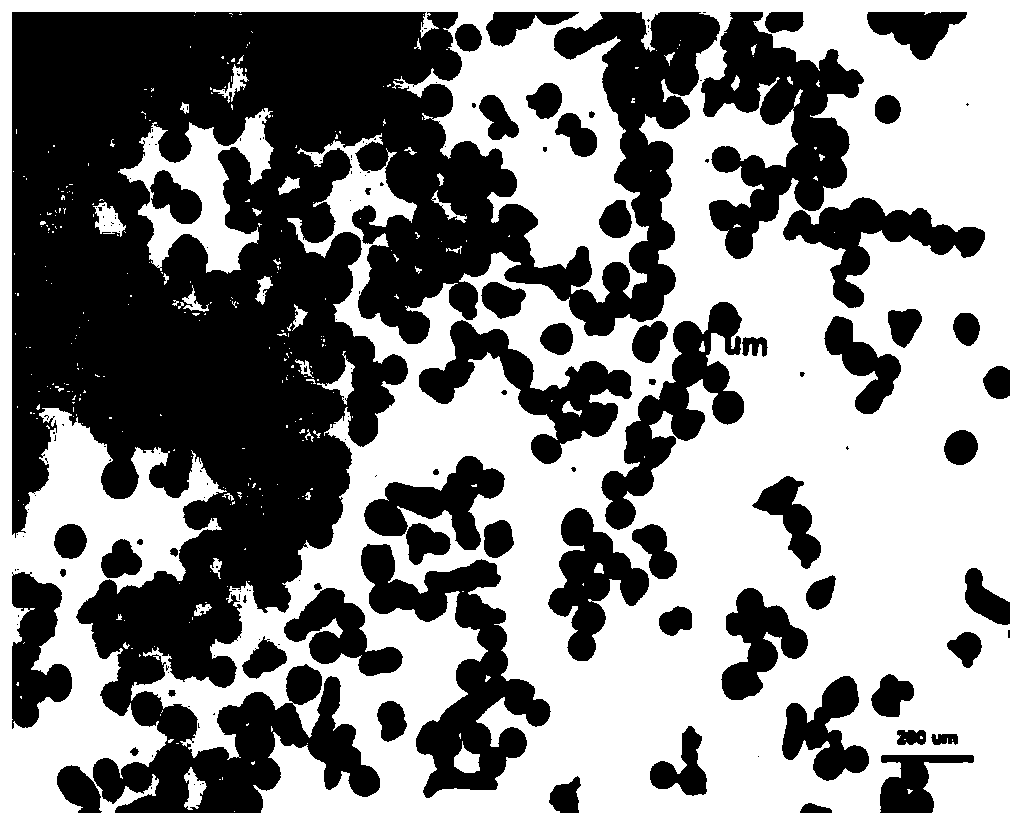

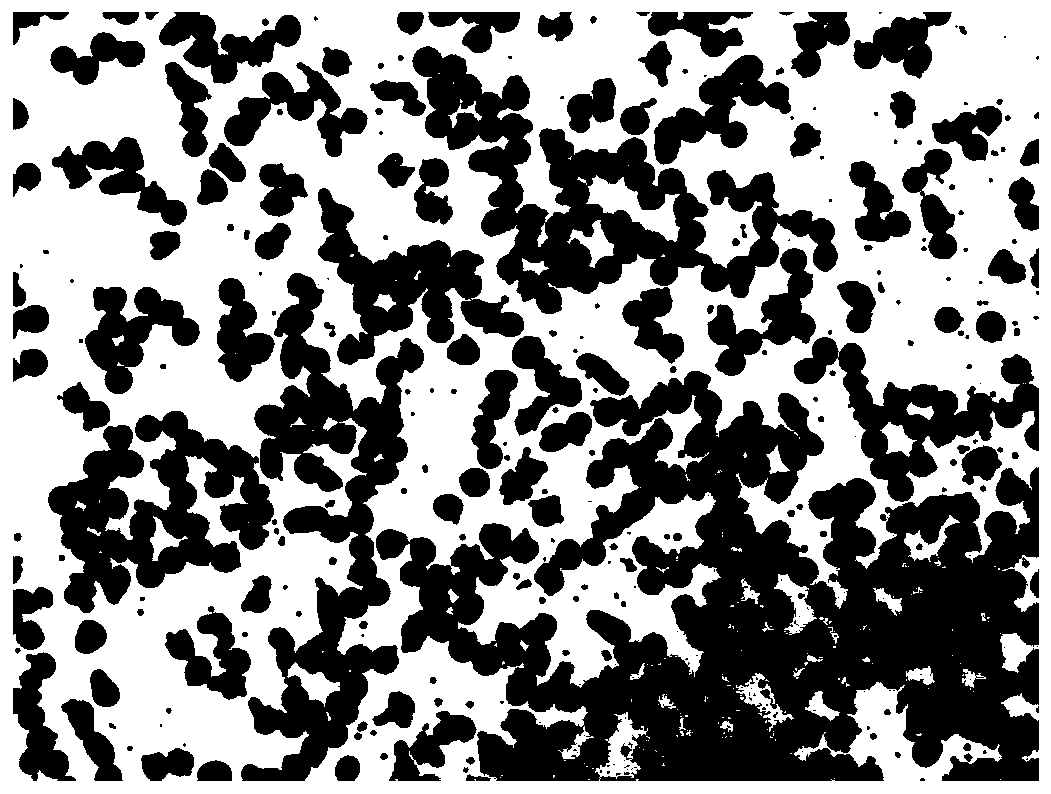

Image

Examples

Embodiment 1

[0058] A preparation method of highly fine-grain atomized copper alloy powder, the alloy includes the following elements by mass percentage: lead Pb%: 5%; tin Sn%: 15%; zinc Zn%: 6%; nickel Ni%: 2%; Surplus is copper Cu, and the preparation method of described high fine-grain atomized copper alloy powder comprises the following steps:

[0059] (1) Taking raw materials according to the above-mentioned alloy composition to complete the batching;

[0060] (2) After batching, the material is smelted and sintered in an intermediate frequency furnace, and rare earth additives and grain growth inhibitors are added during the smelting process;

[0061] (3) atomize in the atomizing system then;

[0062] (4) drying and cooling;

[0063] (5) After screening;

[0064] (6) Copper alloy powder is obtained by batch packaging;

[0065] Wherein, in step (2), the intermediate frequency furnace is smelted, and the raw materials enter the intermediate frequency furnace for smelting at 1300° C...

Embodiment 2

[0083] A preparation method of highly fine-grain atomized copper alloy powder, the alloy includes the following elements by mass percentage: lead Pb%: 27%; tin Sn%: 0.5%; zinc Zn%: 1.0%; Ni%: 9 %; Balance is copper Cu, comprises the following steps:

[0084] (1) Taking raw materials according to the above-mentioned alloy composition to complete the batching;

[0085] (2) After batching, the material is smelted in an intermediate frequency furnace, and rare earth additives and grain growth inhibitors are added during the smelting process;

[0086] (3) atomize in the atomizing system then;

[0087] (4) drying and cooling;

[0088] (5) After screening;

[0089] (6) Copper alloy powder is obtained by batch packaging;

[0090] Wherein, in step (2), the intermediate frequency furnace is smelted, and the raw materials enter the intermediate frequency furnace for smelting at 1400° C. for 60 minutes, and each material metal is alloyed in the intermediate frequency furnace;

[0091...

Embodiment 3

[0108] A method for preparing highly fine-grain atomized copper alloy powder, the alloy includes the following elements by mass percentage: lead Pb%: 8%; tin Sn%: 8%; zinc Zn%: 3%; Ni%: 6% %; Surplus is copper Cu, and the preparation method of described high-fine-grain atomized copper alloy powder comprises the following steps:

[0109] (1) Taking raw materials according to the above-mentioned alloy composition to complete the batching;

[0110] (2) After batching, the material is smelted in an intermediate frequency furnace, and rare earth additives and grain growth inhibitors are added during the smelting process;

[0111] (3) atomize in the atomizing system then;

[0112] (4) After screening;

[0113] (5) Copper alloy powder is obtained by batch packaging;

[0114] Wherein, in step (2), the intermediate frequency furnace is smelted, the raw materials enter the intermediate frequency furnace and are smelted at 1250° C. for 50 minutes, and each material metal is alloyed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com