A method for buffer system to control the viscosity of iron oxide yellow

A technology of iron oxide yellow and buffer system, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, fibrous filler, etc. It can solve the problems of high fluidity resistance of paint, change of pigment hue, and large energy consumption, etc., and reach the particle surface Smooth, reduced aspect ratio, uniform growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

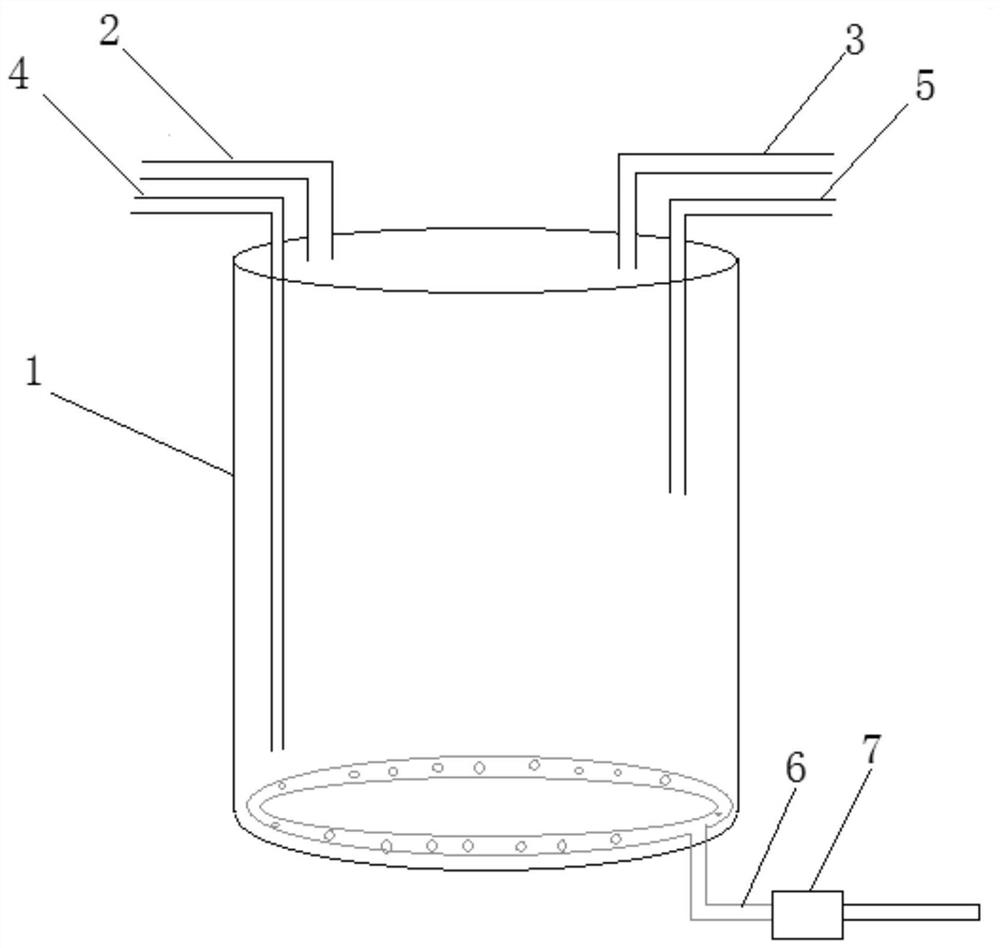

Image

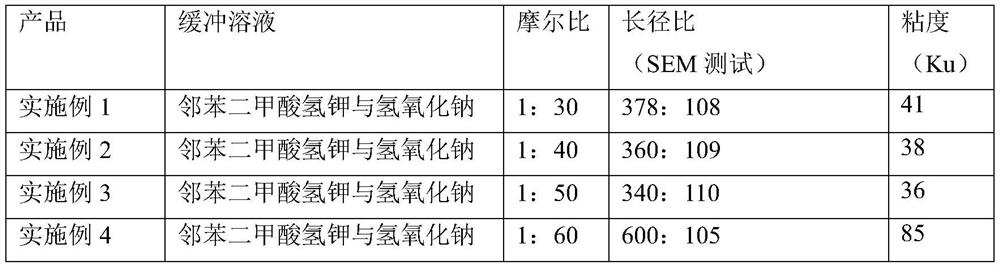

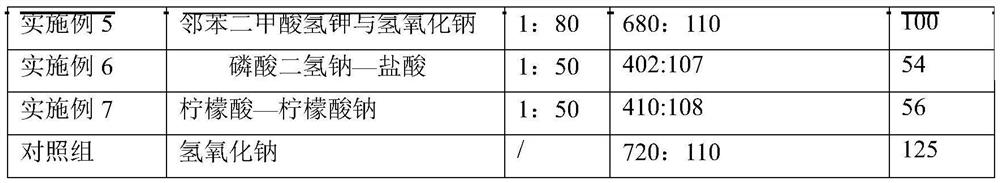

Examples

Embodiment 1

[0034] 1) Seed crystal production:

[0035] A: Raw material configuration: 50m 3 Add ferrous sulfate solution with a concentration of 1.5mol / L into the stainless steel reaction barrel, and then add a volume of 7m 3 Sodium hydroxide solution with a concentration of 2.5mol / L, while controlling the reaction temperature at 25-35°C;

[0036] B: Air volume control: Control the total reaction time to 14-17h, and pass air to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230m 3 / h, after 7-10h, the air volume is controlled at 460m 3 / h. The final material of the reaction is stored separately as a seed crystal;

[0037] 2) Add buffer system for oxidation:

[0038] A: Put the prepared seed crystals into the reaction barrel, then add a certain amount of water to dilute, and control the ferrous iron content between 1.34mol / L and 1.52mol / L;

[0039] B: For the six groups of reaction barrels, the feed liquid is fed into the air from the...

Embodiment 2

[0045] 1) Seed crystal production:

[0046] A: Raw material configuration: 50m 3 Add ferrous sulfate solution with a concentration of 1.5mol / L into the stainless steel reaction barrel, and then add a volume of 7m 3 Sodium hydroxide solution with a concentration of 2.5mol / L, while controlling the reaction temperature at 25-35°C;

[0047] B: Air volume control: Control the total reaction time to 14-17h, and pass air to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230m 3 / h, after 7-10h, the air volume is controlled at 460m 3 / h. The final material of the reaction is stored separately as a seed crystal;

[0048] 2) Add buffer system for oxidation:

[0049] A: Put the prepared seed crystals into the reaction barrel, then add a certain amount of water to dilute, and control the ferrous iron content between 1.34mol / L and 1.52mol / L;

[0050] B: For the six groups of reaction barrels, the feed liquid is fed into the air from the b...

Embodiment 3

[0056] 1) Seed crystal production:

[0057] A: Raw material configuration: 50m 3 Add ferrous sulfate solution with a concentration of 1.5mol / L into the stainless steel reaction barrel, and then add a volume of 7m 3 Sodium hydroxide solution with a concentration of 2.5mol / L, while controlling the reaction temperature at 25-35°C;

[0058] B: Air volume control: Control the total reaction time to 14-17h, and pass air to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230m 3 / h, after 7-10h, the air volume is controlled at 460m 3 / h. The final material of the reaction is stored separately as a seed crystal;

[0059] 2) Add buffer system for oxidation:

[0060] A: Put the prepared seed crystals into the reaction barrel, then add a certain amount of water to dilute, and control the ferrous iron content between 1.34mol / L and 1.52mol / L;

[0061] B: For the six groups of reaction barrels, the feed liquid is fed into the air from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com