Manufacturing method of nano cerium oxide

A nano-cerium oxide, manufacturing method technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of poor dispersibility, hindering application, insufficient dispersibility of nanomaterials, etc., and achieves reduced separation and good dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 (36nm cerium oxide)

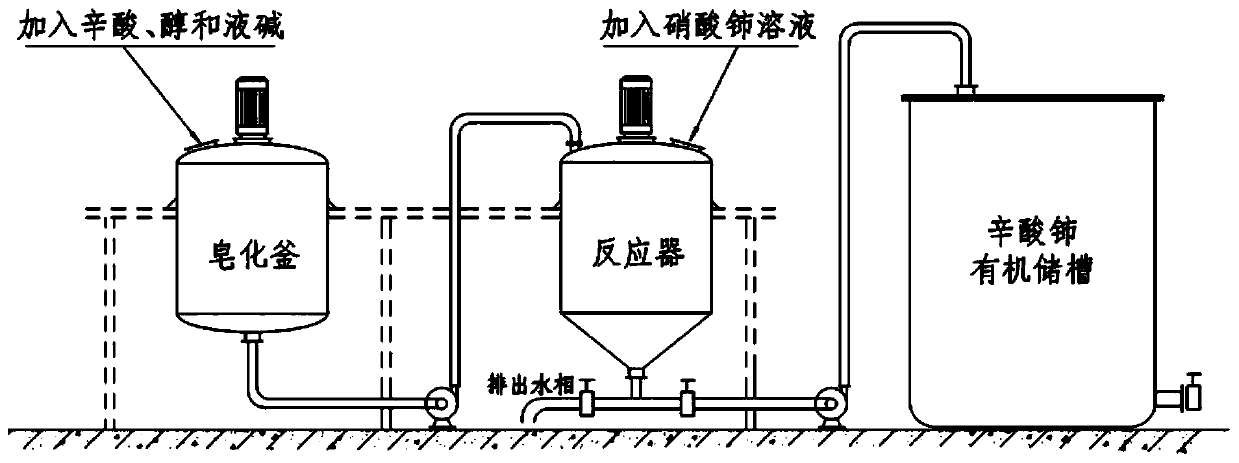

[0027] 1) Preparation of cerium octanoate (such as figure 1 shown)

[0028] Mix 30 liters of octanoic acid and 90 liters of 1-nonanol evenly, add 5.5 liters of 30% sodium hydroxide solution, and add them to the saponification kettle; stir well, and pump the reaction solution into the reactor after the reaction is completed, then add cerium nitrate solution 30 liters (with CeO 2 : 3.2kg), after reacting for 20 to 30 minutes, leave it still; remove the aqueous phase of the lower floor, and the organic phase of the upper floor is the cerium octoate solution, which is pumped into the cerium octoate organic storage tank for subsequent use.

[0029] 2) spray combustion, collection (such as figure 2 shown)

[0030] Introduce cerium octoate into the combustion nozzle, atomize with 1.1Mpa compressed air, and ignite and burn in the combustion chamber at the same time. The flame temperature is 750-850°C. After the combustion exhaust gas pass...

Embodiment 2

[0031] Embodiment 2 (52nm cerium oxide)

[0032] 1) Preparation of cerium octanoate (such as figure 1 shown)

[0033] Mix 30 liters of octanoic acid and 90 liters of 1-nonanol evenly, add 5.5 liters of 30% sodium hydroxide solution, and add them to the saponification kettle; stir well, and pump the reaction solution into the reactor after the reaction is completed, then add cerium nitrate solution 30 liters (with CeO 2 : 3.2kg), after reacting for 20 to 30 minutes, let it stand; remove the water phase of the lower floor, and the organic phase of the upper floor is the cerium octoate solution, which is pumped into the cerium octoate organic storage tank for subsequent use.

[0034] 2) spray combustion, collection (such as figure 2 shown)

[0035] Introduce cerium octoate into the combustion nozzle, atomize with 1.0Mpa compressed air, and ignite and burn in the combustion chamber at the same time. The flame temperature is 750-850°C. The combustion tail gas is introduced int...

Embodiment 3

[0036] Embodiment 3: (18nm cerium oxide)

[0037] 1) Preparation of cerium octanoate (such as figure 1 shown)

[0038] Mix 30 liters of octanoic acid and 90 liters of 1-nonanol evenly, add 5.5 liters of 30% sodium hydroxide solution, and add them to the saponification kettle; stir well, and pump the reaction solution into the reactor after the reaction is completed, then add cerium nitrate solution 30 liters (with CeO 2 : 3.2kg), leave standstill after reacting for 20~30 minutes; Remove the aqueous phase of lower floor, the organic phase of upper strata is cerium octanoate solution, pumps into cerium octanoate organic storage tank for subsequent use;

[0039] 2) spray combustion, collection (such as figure 2 shown)

[0040] The diluted cerium octanoate is introduced into the combustion nozzle, atomized with 1.2Mpa compressed air, and ignited and burned in the combustion chamber at the same time. The flame temperature is 700-800°C. Collected for the second time, the nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com