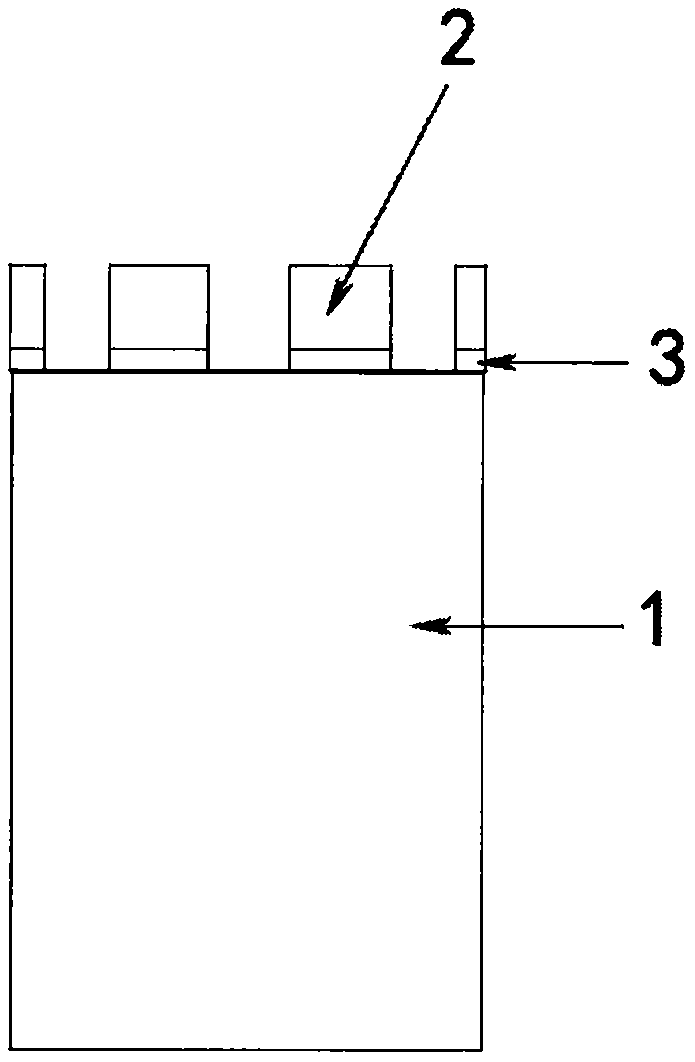

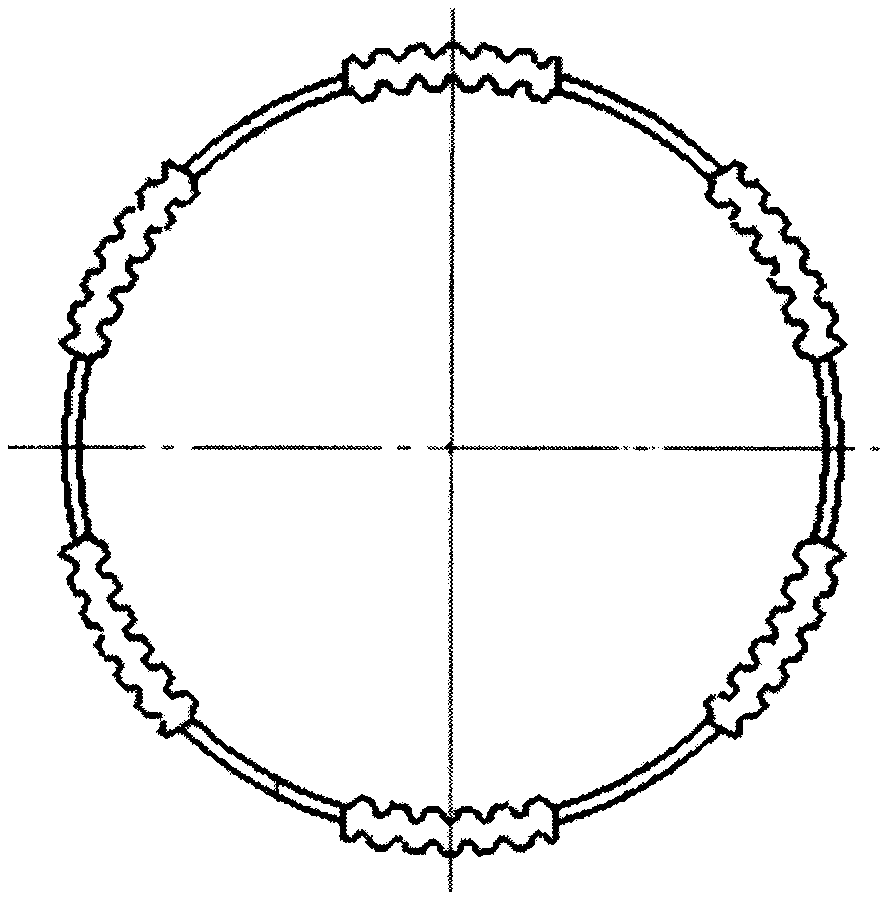

Diamond coring bit and a laser welding preparation process thereof

A coring bit and laser welding technology, applied in drill bits, manufacturing tools, drilling equipment, etc., can solve the problems of difficult coring, slow drilling speed, harsh environmental requirements, etc., and achieve excellent welding strength, smooth water cooling, and safety. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]In this embodiment, the composition (parts by weight) of the raw materials for diamond cutter head preparation: 20 parts of copper, 33 parts of iron, 12 parts of nickel, 29 parts of tungsten, 5.5 parts of tin, 0.5 part of rare earth alloy, 2.2 parts of diamond, and 0.0025 part of liquid paraffin .

[0046] The rare earth alloy is a La-Ni alloy, wherein La is 25wt.%, and the balance is Ni.

[0047] The raw material powder composition of the transition layer in this embodiment is: Co 21.2wt.%, Cu 8wt.%, Ni 3.05wt.%, and the balance is Fe.

[0048] The diamond cutter head and the transition layer are sintered together by hot pressing sintering technology, and the specific process is as follows:

[0049] After mixing the raw materials of the cutter head evenly in proportion, cold press molding is carried out first to obtain a prefabricated cutter head; after the raw material powder of the transition layer is mixed uniformly, cold press molding is also carried out to obtain ...

Embodiment 2

[0069] In this embodiment, the composition (parts by weight) of the raw materials for diamond cutter head preparation: 25 parts of copper, 35 parts of iron, 15 parts of nickel, 31 parts of tungsten, 4.5 parts of tin, 0.25 parts of rare earth alloy, 2.2 parts of diamond, and 0.0042 parts of liquid paraffin .

[0070] Others are all the same as in Example 1.

[0071] The coring diamond drill bit prepared in this embodiment has no macroscopic defects such as air holes and cracks in the weld seam after testing. The bending strength of the cutter head is greater than 1872N / mm 2 , welding strength 45N.m.

Embodiment 3

[0073] In this embodiment, the composition (parts by weight) of the raw materials for diamond cutter head preparation: 21 parts of copper, 30 parts of iron, 11 parts of nickel, 31 parts of tungsten, 4.5 parts of tin, 0.40 parts of rare earth alloy, 2.4 parts of diamond, and 0.0040 parts of liquid paraffin .

[0074] Others are all the same as in Example 1.

[0075] The coring diamond drill bit prepared in this embodiment has no macroscopic defects such as air holes and cracks in the weld seam after testing. The bending strength of the cutter head is greater than 1875N / mm 2 , welding strength 42N.m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com