A core box specially used for producing the core shell of the front pump cover

A technology of covering core and core core, applied in casting and molding equipment and other directions, can solve the problems of easy damage to core core and low core extraction efficiency, and achieve the effect of improving core extraction efficiency, reducing edge damage and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

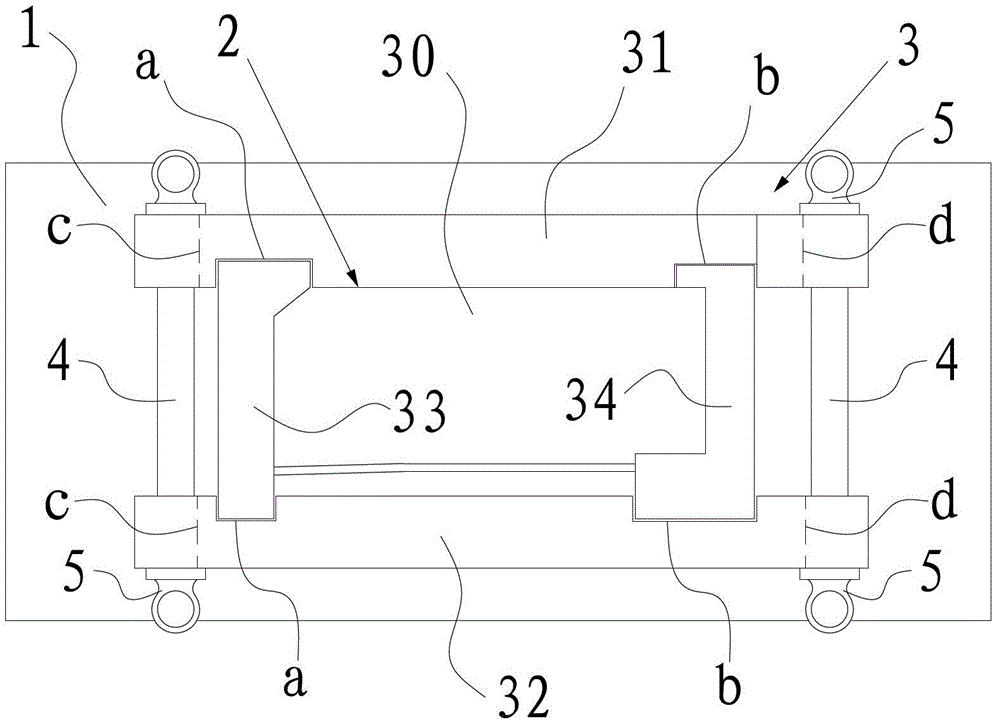

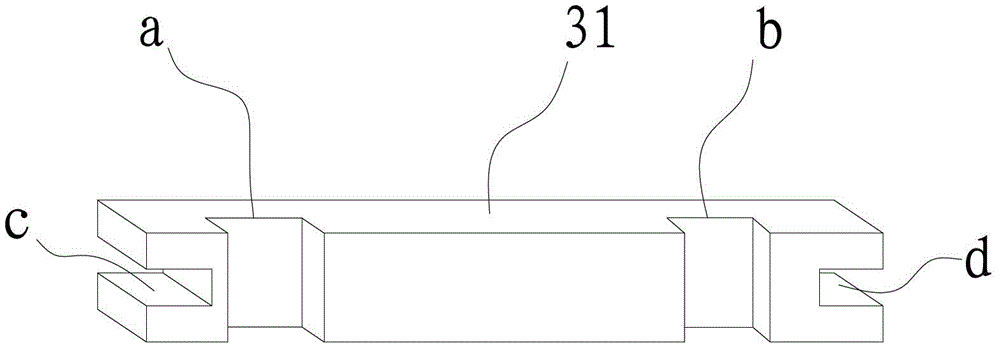

[0017] Such as figure 1 with figure 2 As shown, the core box dedicated to the production of the core shell of the front pump cover of this embodiment includes a bottom plate 1 and a core mold 3 disposed on the bottom plate 1 and forming a cavity 2 with the bottom plate 1, wherein the cavity 2 and the front pump The outer shape of the cover core shell is the same. The core mold 3 includes a bottom mold 30 with the same shape as one side of the front pump cover core shell, and a plurality of modules surrounding the bottom mold 30. The plurality of modules The core box can be detachably connected together, and the core box also includes a locking mechanism for relatively locking a plurality of modules.

[0018] The above-mentioned multiple modules consist of four, and the four modules are the first module 31, the second module 32, the third module 33, and the fourth module 34 respectively arranged along the length and width directions of the cavity 2. The first module 31 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com