Waterborne polyurethane dispersion and single-component waterborne adhesive with same for PVC (polyvinyl chloride) calendered coatings

A water-based polyurethane and dispersion technology, applied in the direction of textiles and papermaking, etc., can solve the problems of reduced service life, strong taste, residue, etc., and achieve the effect of low cost, low solid content, and stable peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

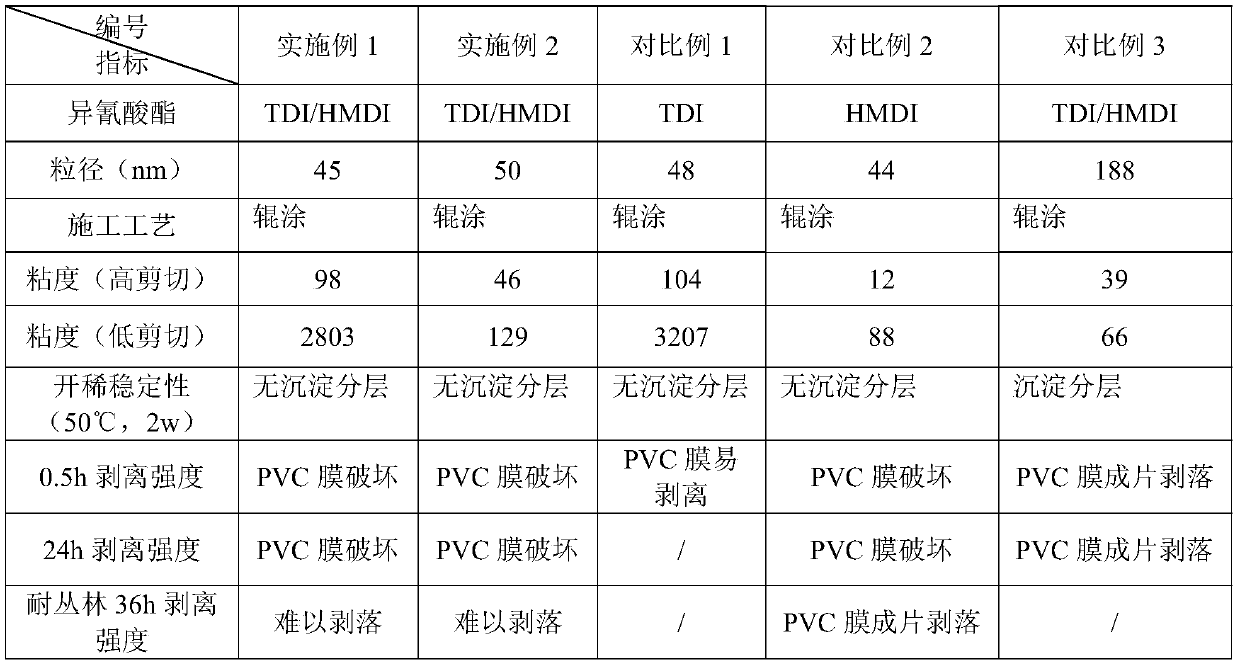

Examples

Embodiment 1

[0044] Add 240g of dehydrated poly(1,4-butylene adipate) (molecular weight: 3000), 50g of TDI-80, 20g of HMDI, 36.5g of acetone, and an appropriate amount of catalyst (bismuth isooctanoate, 100ppm) to the nitrogen inlet and outlet. In a 1 L four-neck round bottom flask, the mixture was stirred at 60-80° C. until NCO reached 6.8%. Add 8g of 1,4-butanediol, 14g of dimethylolpropionic acid and 80g of acetone and continue the reaction at 60°C until NCO reaches 1.70. Then add 200g of acetone to dilute and cool down to 40°C, add 9.51g of triethylamine to neutralize for 10 minutes, add 503g of water under high-speed stirring to stir and disperse, add 3.0g of ethylenediamine to continue stirring for 15 minutes. After separating the acetone from the obtained acetone-containing emulsion by distillation, a solvent-free aqueous polyurethane dispersion with a particle size of 45 nm was obtained.

[0045] Take 100 parts of the obtained water-based polyurethane and add it into the dispersio...

Embodiment 2

[0047] Add 240g of dehydrated poly-1,4-butylene adipate (molecular weight: 2000), 50g of TDI-80, 35g of HMDI, 36.6g of acetone, and an appropriate amount of catalyst (bismuth isooctanoate, 100ppm) into the nitrogen inlet and outlet. In a 1 L four-neck round bottom flask, the mixture was stirred at 60-80° C. until NCO reached 6.99%. Add 8g of 1,4-butanediol, 15g of dimethylolpropionic acid and 80g of acetone and continue the reaction at 60°C until the NCO reaches 1.81. Then add 210g of acetone to dilute and cool down to 40°C, add 10.2g of triethylamine to neutralize for 10min, add 503g of water under high-speed stirring to stir and disperse, add 4.2g of ethylenediamine to continue stirring for 15min. After separating the acetone from the obtained acetone-containing emulsion by distillation, a solvent-free aqueous polyurethane dispersion with a particle size of 50 nm was obtained.

[0048] Take 100 parts of the obtained water-based polyurethane and add it into the dispersion ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com