Hydrochloric acid regenerated flue gas emission system and emission method

A technology for regenerating flue gas and exhaust system, which is applied in the field of hydrochloric acid regeneration flue gas exhaust system, which can solve the problems of hydrogen chloride and dust treatment not up to standard, and achieve the effect of ensuring long-term reliable operation, good corrosion resistance, and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

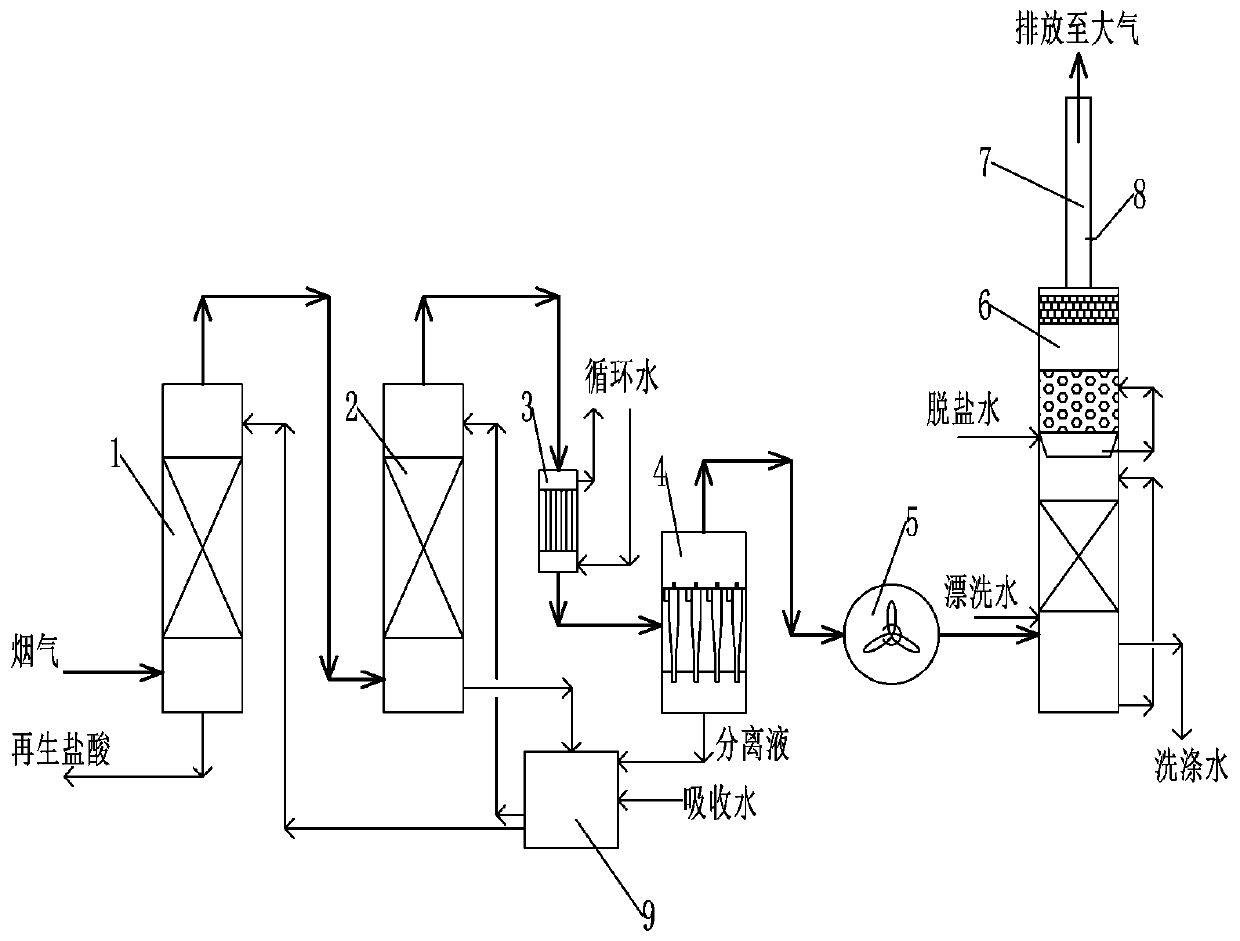

[0054] Utilize the hydrochloric acid regeneration flue gas ultra-low discharge system provided by the present invention to be 3.5m 3 / h hydrochloric acid regeneration unit for processing, among which, the device parameters involved in the hydrochloric acid regeneration flue gas ultra-low emission system are as follows:

[0055] The inlet temperature of the primary absorption tower 1 is 88-96°C, and the flue gas intake volume of the primary absorption tower 1 is 8700-9500Nm 3 / h, the instant spray volume is 3.5m 3 / h of absorbed water; the area of flue gas cooler 3 is 350m 2 , the cooling capacity is 1300000Kcal / h; the gas-liquid cyclone separator 4 is equipped with 30 pieces with a rated flow rate of 300m 3 / h ceramic cyclone; the flue gas temperature at the outlet of the flue gas cooler 3 is 55-60°C, the outlet gas temperature of the chimney 7 is 60°C, and the hydrogen chloride content is 13.8mg / m 3 , the concentration of dust particles is 9.5mg / m 3 , to achieve ultra-l...

Embodiment 2

[0058] The hydrochloric acid regeneration flue gas ultra-low emission system provided by the present invention is used to treat the hydrochloric acid regeneration unit with a processing capacity of 6.0m3 / h, wherein the device parameters involved in the hydrochloric acid regeneration flue gas ultra-low emission system are as follows:

[0059] The inlet temperature of the primary absorption tower 1 is 88-96°C. The flue gas intake volume of the primary absorption tower 1 is 14000-16000Nm 3 / h, the instant spray volume is 6.0m 3 / h of absorbed water. The area of flue gas cooler 3 is 600m 2 , the cooling capacity is 2300000Kcal / h. The gas-liquid cyclone separator 4 is assembled by 32 with a rated flow rate of 500m 3 / h ceramic cyclone sub. The outlet gas temperature of flue gas cooler 3 is 55-60°C, the outlet flue gas temperature of chimney 7 is 60°C, and the hydrogen chloride content is 15.4mg / m 3 , the concentration of dust particles is 8.9mg / m 3 , to achieve ultra-low s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com