Roasting furnace cover and manufacturing method thereof

A technology for a roasting furnace and a furnace cover, which is applied to the field of roasting furnace cover and its preparation, can solve the problems of buried roasting furnace operation, increased energy consumption of roasting furnace operation, and increased use cost of furnace cover, and achieves remarkable thermal insulation effect. ,Easy to open and handle,reduce the effect of running energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing the furnace cover of the roasting furnace described in the above technical solution, comprising the following steps:

[0031] a) melting and fiberizing the ceramic fiber raw materials to obtain ceramic fiber filaments;

[0032] b) Collecting the ceramic fiber filaments to obtain a ceramic fiber blank;

[0033] c) performing drum needle punching on the ceramic fiber blank to obtain an integral ceramic fiber module;

[0034] d) Cutting and calcining the integral ceramic fiber module to obtain the furnace cover of the roasting furnace.

[0035] In the preparation method provided by the invention, the ceramic fiber raw material is firstly melted. Wherein, the ceramic fiber raw material preferably includes Al 2 o 3 , SiO 2 and ZrO 2 ; The Al 2 o 3The content in the ceramic fiber raw material is preferably 32 to 56 parts by weight, specifically 32 parts by weight, 33 parts by weight, 34 parts by weight, 35 par...

Embodiment 1

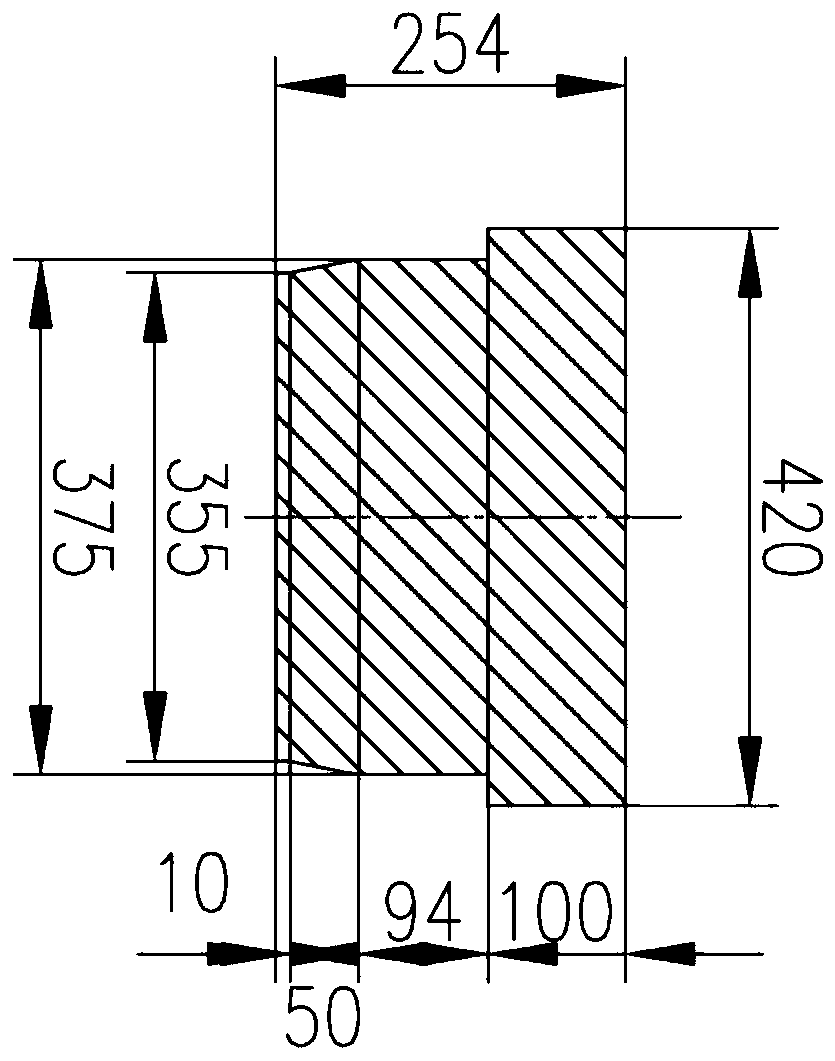

[0044] The required raw materials alumina, silica powder according to Al 2 o 3 : SiO 2 = The ratio of 44:56 is mixed evenly; then it is melted at 2100°C, and the obtained melt is spun in a spinning machine, the roller frequency of the spinning machine is set at 52Hz, and the fiber forming distance is 1000mm, and the diameter is obtained. 3.4μm ceramic fiber filaments; then the ceramic fiber filaments are processed in the cotton collector to form ceramic fiber blanks with a thickness of 100mm; then the formed ceramic fiber blanks are needle-punched on a drum needle punching machine, and the formed products are needle-punched Density at 10 needles / cm 2 , bulk density is 220kg / m 3 , with a thickness of 200mm; then the formed product is cut into water-cut (water-cut pressure 22MPa) as figure 1 the shape shown, figure 1 It is a schematic diagram of the side view structure of the furnace cover provided by Embodiment 1 of the present invention, figure 1 The units corresponding ...

Embodiment 2

[0051] The required raw materials alumina, silica powder, zircon sand according to Al 2 o 3 : SiO 2 : ZrO 2 = 36:44:20 mixing ratio evenly; then melted at 2100°C, and the obtained melt was spun in a spinning machine, the roller frequency of the spinning machine was set at 53Hz, and the fiber forming distance was 1000mm, and the obtained Ceramic fiber filaments with a diameter of 3.2μm; then the ceramic fiber filaments are processed in a cotton collector to form a ceramic fiber blank with a thickness of 100mm; then the formed ceramic fiber blanks are needled in a drum needle punching machine, and the formed product Needling density is 12 needles / cm 2 , bulk density is 240kg / m 3 , with a thickness of 200mm; then the formed product is water-cut with a water-cut pressure of 22MPa; then calcined at 1100°C for 3 hours; finally, the calcined product is engraved into such as figure 2 The carbon roaster furnace cover shown. figure 2 It is a schematic diagram of the side view st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com