Heavy raw oil hydrocracking method and system

A hydrocracking and raw oil technology, applied in chemical instruments and methods, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of adding fixed bed hydrotreating reactors, high cost, etc., and achieve conversion rate and selectivity The effect of high and low hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

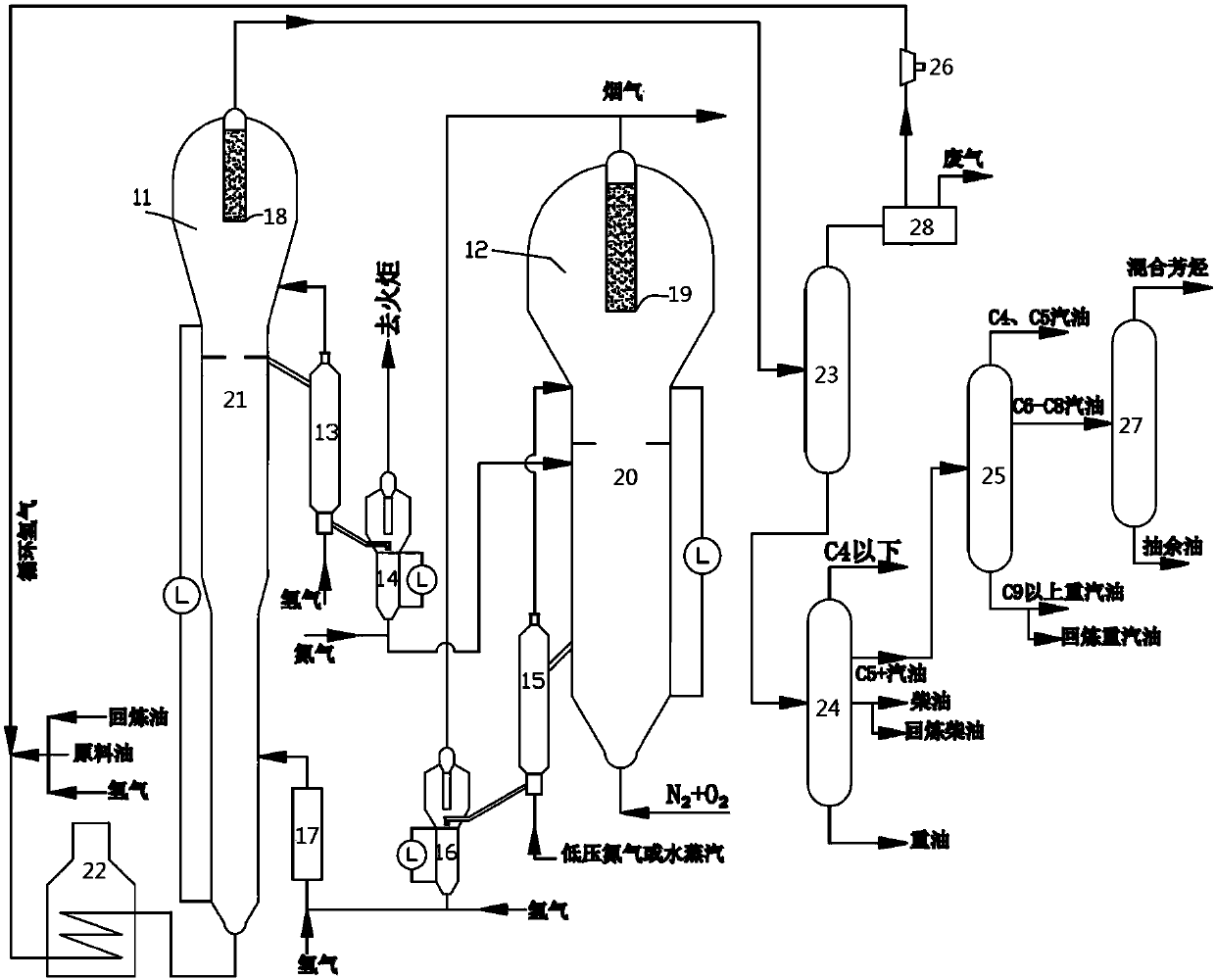

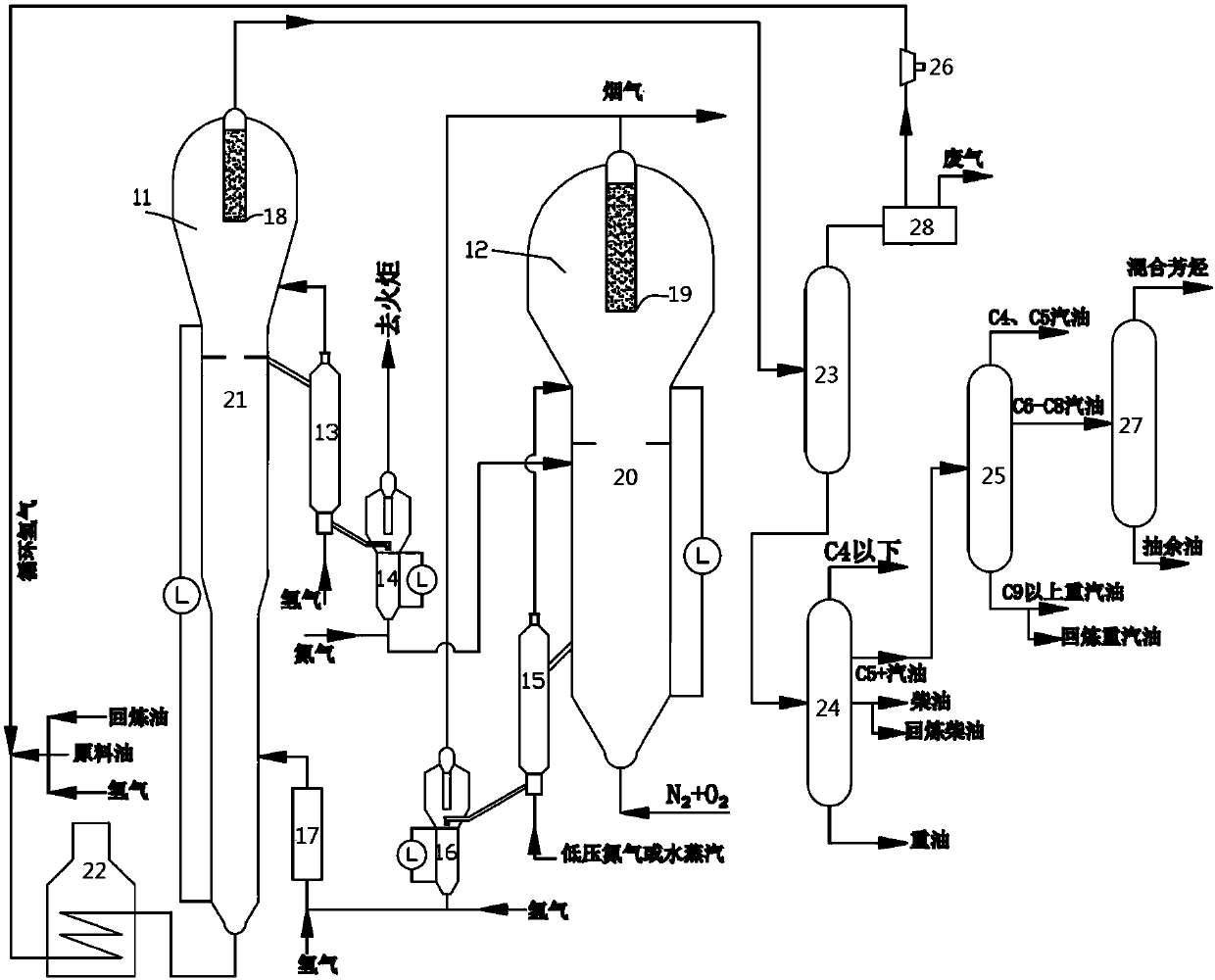

Method used

Image

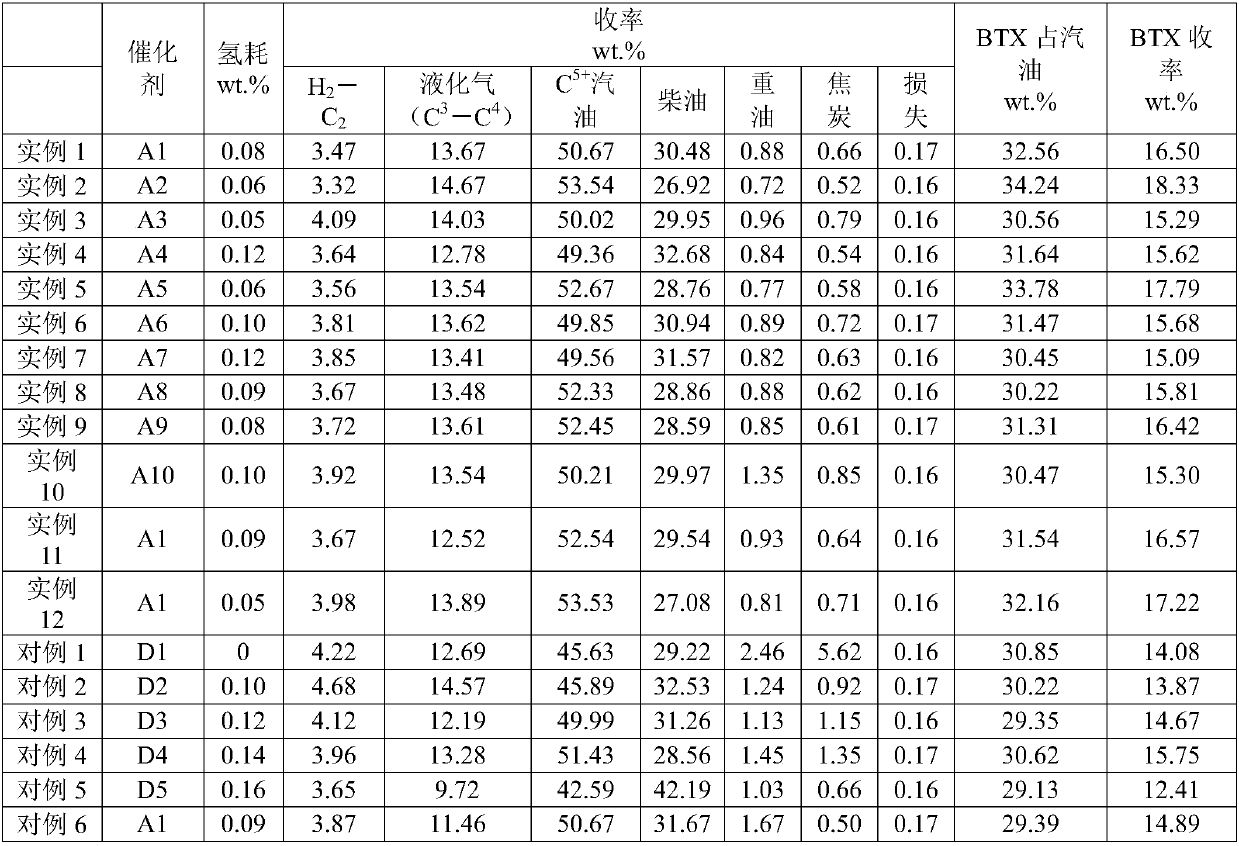

Examples

preparation example Construction

[0072] The silicon oxide source can be the silicon oxide source commonly used in the preparation of binders in the art, such as diatomaceous earth, expanded perlite, kaolin, siliceous rock, layered clay, hydrolyzed silica, macroporous oxide One or more of silicon and silica gel.

[0073] According to the present invention, the amount of the alumina source and the silica source is preferably such that the content of the binder in the resulting catalyst is within the range described above, preferably such that the weight ratio of alumina and silica in the binder is 100: 20-150, preferably 100:30-100. For example, the weight ratio of alumina source and silica source is 100:50-150, preferably 100:55-120, more preferably 100:60-100.

[0074] According to the invention, the binder precursor slurry is acidified, wherein the acid preferably brings the binder precursor slurry to a pH of 1-5. The acid may be one or more of organic acids and inorganic acids, such as one or more of hydr...

Embodiment 1

[0152] This example is used to illustrate the hydrocracking catalyst and its preparation method of the present invention.

[0153] (1) USY molecular sieves (purchased from Sinopec Catalyst Qilu Branch, with a dry basis content of 3kg), ZSM-5 molecular sieves (purchased from Sinopec Catalyst Qilu Branch, with a dry basis content of 0.8kg), oxidation Zinc powder (purchased from Headhorse Company, purity 99.7%, 0.66kg) was mixed with 6.57kg deionized water, and after stirring for 30 minutes, a mixed slurry containing USY molecular sieve, ZSM-5 molecular sieve and zinc oxide was obtained;

[0154] (2) kaolin (purchased from Suzhou Kaolin Factory S1 series, with a dry basis content of 1.5kg) and pseudoboehmite (purchased from Aluminum Corporation of China Shandong Branch, with a dry basis content of 1.35kg) were stirred and mixed, and then added 5.6kg of deionized water was mixed evenly, and then 500mL of hydrochloric acid (concentration of 30% by weight, purchased from Beijing Che...

Embodiment 2

[0159] This example is used to illustrate the hydrocracking catalyst and its preparation method of the present invention.

[0160] (1) PREHY molecular sieve (purchased from Sinopec Catalyst Qilu Branch, with a dry basis content of 4.6kg), ZRP molecular sieve (purchased from Sinopec Catalyst Qilu Branch, with a dry basis content of 1.2kg), magnesium oxide Powder (purchased from Weifang Lihe Powder Technology Co., Ltd., with a purity of more than 95%, 1.26 kg) was mixed with 8.6 kg of deionized water, and stirred for 30 minutes to obtain a mixed slurry containing PREHY molecular sieve, ZRP molecular sieve and magnesium oxide;

[0161] (2) Expanded perlite (purchased from Mantanghong Abrasives Factory in Gongyi City, with a dry basis content of 2.06kg, 30-60 mesh) and pseudo-boehmite (purchased from China Aluminum Shandong Branch, with a dry basis content of 1.48kg) was stirring and mixing, then added 5.6kg of deionized water and mixed evenly, then added 500mL of hydrochloric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com