Illite/smectite clay containing anti-PID functional master batch for photovoltaic packaging film and preparation method for illite/smectite clay containing anti-PID functional master batch

A technology for encapsulating films and functional masterbatches, applied in the direction of films/sheets without carriers, adhesives, non-polymer adhesive additives, etc., can solve the problems of no anti-PID function, low battery performance, etc. Burning effect, excellent compatibility, and density-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

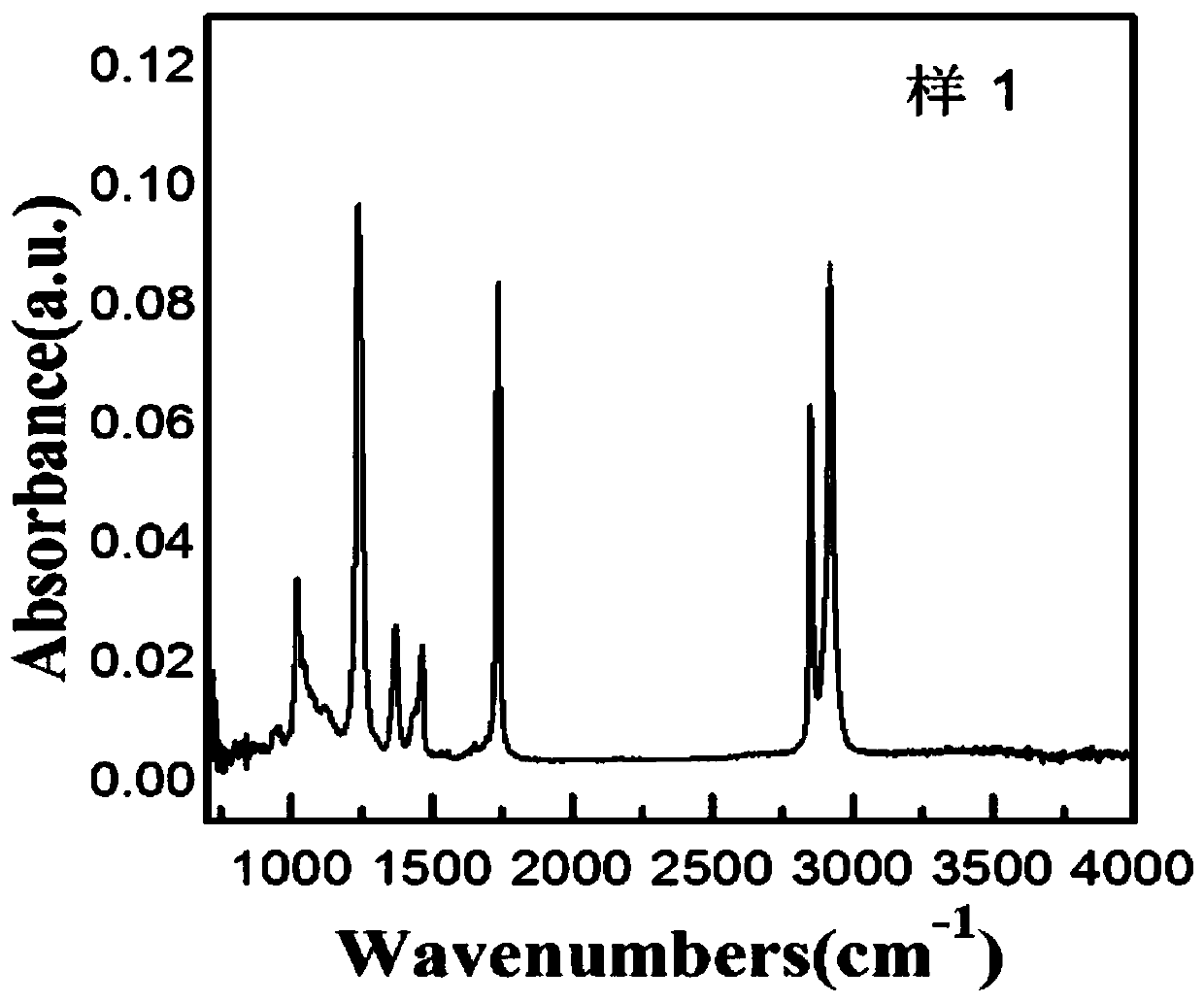

Embodiment 1

[0044] An anti-PID functional masterbatch for photovoltaic encapsulation films containing Il / Mongolian clay, said masterbatch is composed of the following components in terms of weight percentage: EVA resin (E280PV (SAMSUNG TOTAL)) with a vinyl acetate content of 25% 50 %, modified zirconium phosphate crystal (Mianzhu Yaolong Chemical Co., Ltd.) 20%, crosslinking agent (di(4-methylbenzoyl) peroxide) 6%, silane coupling agent (methyl vinyl dimethyl Oxysilane) 1.5%, Nanoil / Mongolian clay with a particle size of 25nm (Zhejiang Kaideli Chemical Co., Ltd.) 15%, co-crosslinking agent (methyl triallyl isocyanurate) 5.5%, anti-ultraviolet Absorbent (2,4-dihydroxybenzophenone) 0.50%, light stabilizer (PR-31) (Clariant) 2.5%, and antioxidant BHT 1.5%.

[0045] The preparation method of the anti-PID functional masterbatch for the photovoltaic encapsulation film containing Iraqi / Mongolian clay is as follows:

[0046] (1) Preparation of modified zirconium phosphate crystals: Pour 50mL of ...

Embodiment 2

[0051] An anti-PID functional masterbatch for photovoltaic encapsulation films containing Iraqi / Mongolian clay, said masterbatch is composed of the following components in terms of weight percent: EVA resin (E262PV (Hanwha Total)) with a vinyl acetate content of 28% 88%, modified zirconium phosphate crystal (Mianzhu Yaolong Chemical Co., Ltd.) 4%, crosslinking agent (dicumyl peroxide) 0.5%, silane coupling agent (vinyl triethoxysilane) 0.5%, particle size 95nm nano-yi / Mongolian clay (Zhejiang Kaideli Chemical Co., Ltd.) 5%, co-crosslinking agent (triallyl isopolycyanate) 0.5%, anti-ultraviolet absorber (2-hydroxyl-4-normal octyloxybenzophenone) 0.1%, light stabilizer 944 (Clariant) 0.6% and antioxidant 1076 0.8%.

[0052] The preparation method of the anti-PID functional masterbatch for the photovoltaic encapsulation film containing Iraqi / Mongolian clay is as follows:

[0053] (1) Preparation of modified zirconium phosphate crystals: Pour 50mL of silane coupling agent into 15...

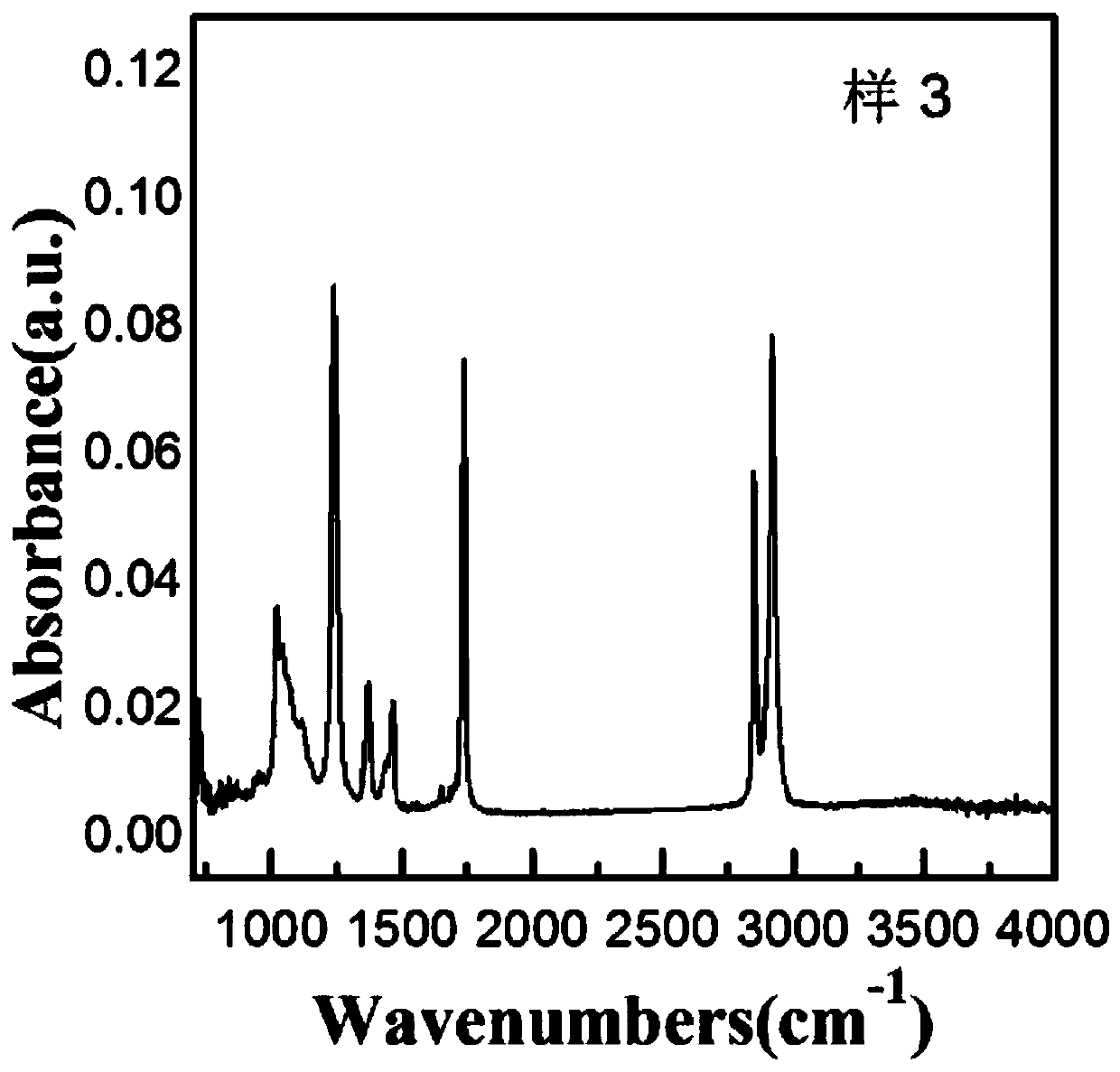

Embodiment 3

[0058] An anti-PID functional masterbatch for photovoltaic encapsulation films containing Il / Mongolian clay, said masterbatch is composed of the following components in terms of weight percentage: EVA resin (E280PV (SAMSUNG TOTAL)) with a vinyl acetate content of 28% 74 %, modified zirconium phosphate crystal (Mianzhu Yaolong Chemical Co., Ltd.) 15%, crosslinking agent (tert-butyl carbon peroxide-2-ethylhexyl ester) 4%, silane coupling agent (vinyltrimethoxysilane ) 0.5%, particle size is 50nm nanometer Yi / Mongolia clay (Zhejiang Kaideli Chemical Co., Ltd.) 3%, co-crosslinking agent (triallyl isopolycyanate) 2.5%, anti-ultraviolet absorber (2- Hydroxy-4-n-octyloxybenzophenone) 0.1%, light stabilizer (PR-25) (Clariant) 0.5%, and antioxidant 264 0.4%.

[0059] The preparation method of the anti-PID functional masterbatch for the photovoltaic encapsulation film containing Iraqi / Mongolian clay is as follows:

[0060] (1) Preparation of modified zirconium phosphate crystals: Pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com