Self-lubricating ceramic tool material with nickel-coated hexagonal boron nitride nanosheet composite powder added and preparation method thereof

A technology of hexagonal boron nitride and composite powder, which is applied in the field of ceramic tool materials, can solve the problems of inability to balance friction reduction performance and mechanical performance, and achieve the effects of improving mechanical performance and cutting performance, improving effect, and improving sensitization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

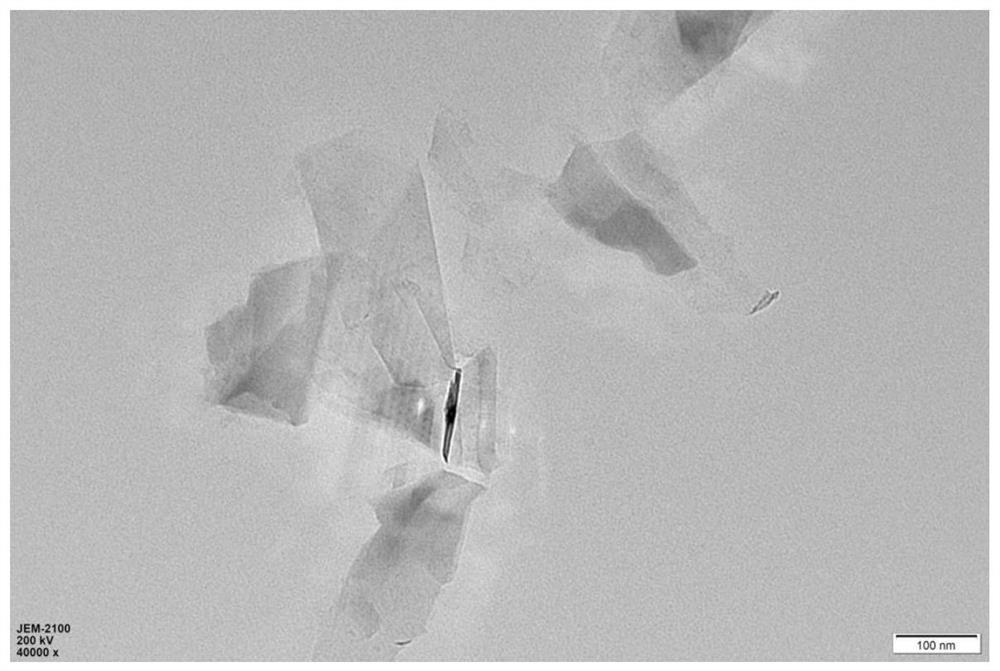

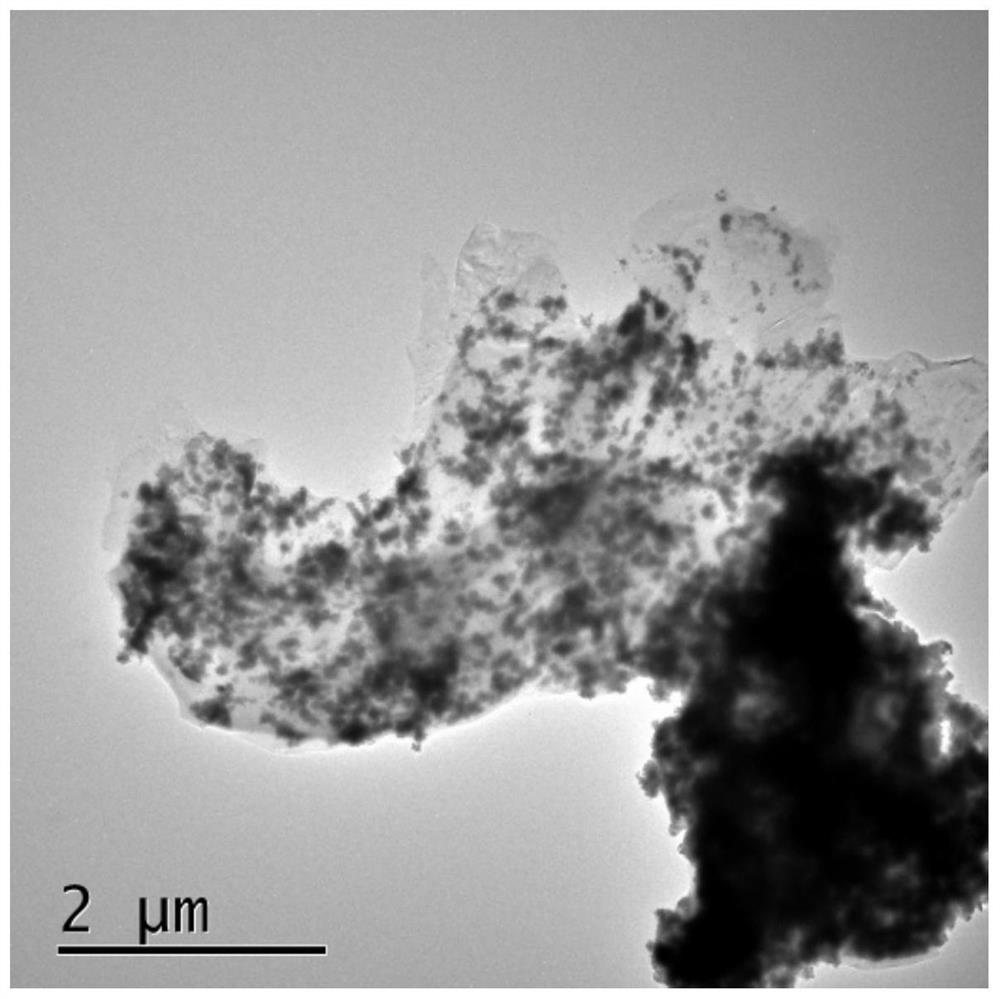

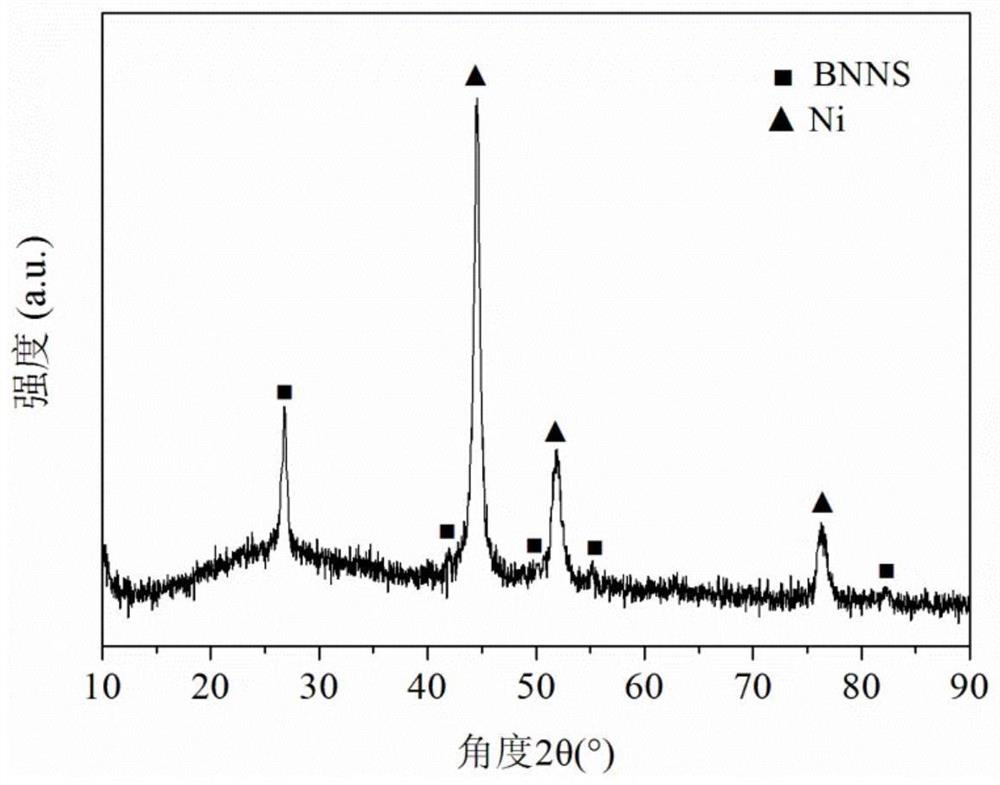

[0059] Example 1: A self-lubricating ceramic tool material with nickel-coated hexagonal boron nitride nanosheet composite powder added, the mass percentage of each component is: α-Al 2 o 3 32.65%, (W,Ti)C 66%, BNNS@Ni 0.35% based on the mass of BNNS in the composite powder, MgO 0.5%, Y 2 o 3 0.5%. The preparation method is as follows:

[0060] (1) Weigh 3.5g SnCl 2 2H 2 O, add 100mL of isopropanol, stir to dissolve, add isopropanol to 350mL, ultrasonically oscillate and stir evenly to obtain a sensitized solution, then add 3g of tin particles; weigh 0.35g of BNNS powder and add it to 300mL of isopropanol for ultrasonication Disperse for 20 minutes, centrifuge and add to the sensitization solution, ultrasonically shake and stir for 10 minutes, filter out the tin particles, centrifuge and wash once with distilled water to obtain sensitized BNNS powder.

[0061] (2) Weigh 0.15g PdCl 2 , add 3mL concentrated hydrochloric acid, stir to dissolve, add distilled water to 500m...

Embodiment 2

[0072] Example 2: A self-lubricating ceramic tool material with nickel-coated hexagonal boron nitride nanosheet composite powder added, the mass percentage of each component is: α-Al 2 o 3 34%, (W,Ti)C 64.5%, BNNS@Ni 0.5% based on the mass of BNNS in the composite powder, MgO 0.5%, Y 2 o 3 0.5%. The preparation method is as follows:

[0073] (1) Weigh 6g SnCl 2 2H 2 O, add 200mL of isopropanol, stir to dissolve, add isopropanol to 500mL, ultrasonically oscillate and stir evenly to obtain a sensitized solution, then add 4g of tin particles; weigh 0.5g of BNNS powder and add it to 400mL of isopropanol for ultrasonication Disperse for 25 minutes, centrifuge and add to the sensitization solution, ultrasonically shake and stir for 12 minutes, filter out tin particles, centrifuge and wash once with distilled water to obtain sensitized BNNS powder.

[0074] (2) Weigh 0.2g PdCl 2 , add 4mL concentrated hydrochloric acid, stir to dissolve, add distilled water to 500mL, then ad...

Embodiment 3

[0082] Example 3: A self-lubricating ceramic tool material with nickel-coated hexagonal boron nitride nanosheet composite powder added, the mass percentage of each component is: α-Al 2 o 3 38.3%, (W,Ti)C 60%, BNNS@Ni 0.7% based on the mass of BNNS in the composite powder, MgO 0.5%, Y 2 o 3 0.5%. The preparation method is as follows:

[0083] (1) Weigh 7.5g SnCl 2 2H 2O, add 300mL of isopropanol, stir to dissolve, add isopropanol to 500mL, ultrasonically oscillate and stir evenly to obtain a sensitized solution, then add 5g of tin particles; weigh 0.7g of BNNS powder and add it to 500mL of isopropanol for ultrasonication Disperse for 30 minutes, centrifuge and add to the sensitization solution, ultrasonically shake and stir for 15 minutes, filter out the tin particles, centrifuge and wash once with distilled water to obtain sensitized BNNS powder.

[0084] (2) Weigh 0.4g PdCl 2 , add 8mL concentrated hydrochloric acid, stir to dissolve, add distilled water to 800mL, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com