Preparation method for copper calcium titanate

A copper calcium titanate and calcium source technology, applied in the field of dielectric ceramic materials, can solve the problems of easy impurity, segregation, and high cost, and achieve the effects of simple operation process, high catalytic activity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

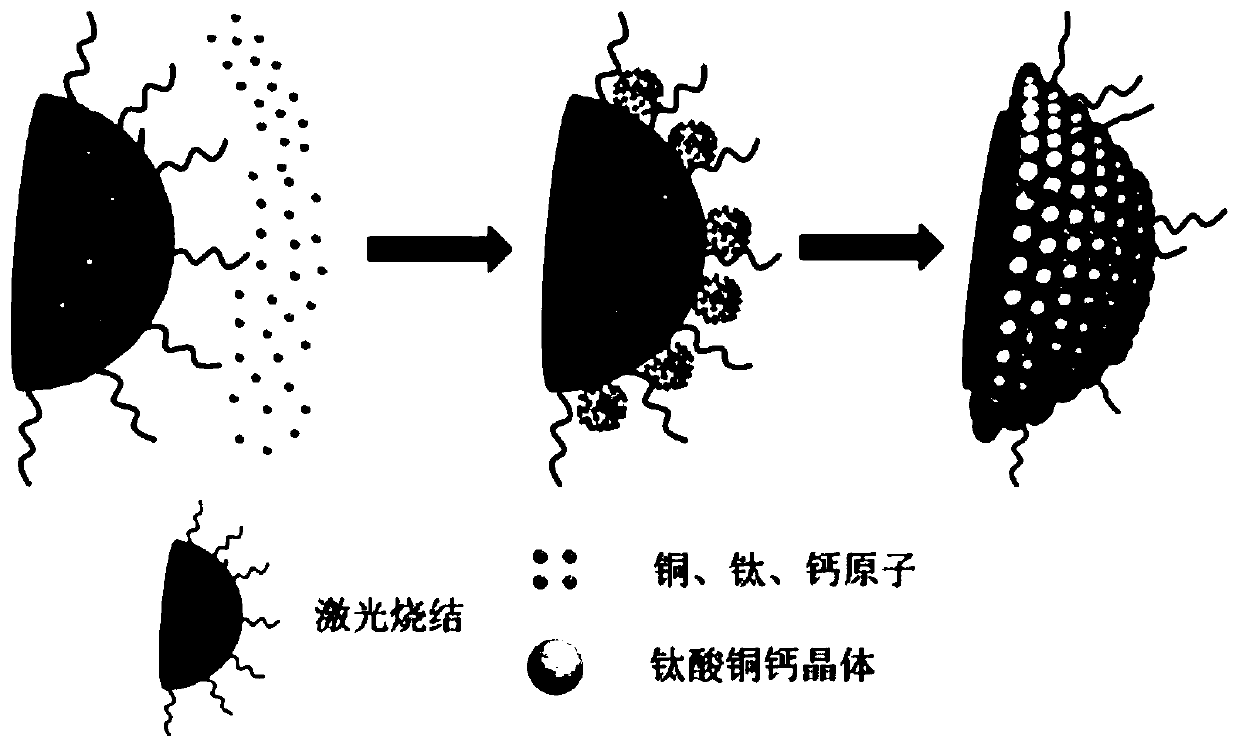

[0036] Such as figure 1 Shown, a kind of preparation method of calcium copper titanate comprises the steps:

[0037] (a), after mixing calcium source, copper source and titanium source, carry out grinding treatment, obtain mixed material;

[0038] (b) performing laser excitation on the mixed material obtained in step (a) under laser irradiation and self-propagating sintering until the mixed material forms black crystals, thus obtaining the calcium copper titanate;

[0039] Wherein, the calcium source, copper source and titanium source are mixed in a molar ratio of calcium, copper and titanium elements of 1:3:4.

[0040] In step (a), the manner of grinding treatment is ball milling for 3 hours at a rotational speed of 200 rad / min.

[0041] The calcium source is calcium oxide; the copper source is copper; the titanium source is titanium dioxide.

[0042] In the step (b), the laser wavelength of the laser irradiation is 980nm.

[0043] In the step (b), the process of laser ir...

Embodiment 2

[0047] A preparation method of calcium copper titanate, comprising the steps of:

[0048] (a), after mixing calcium source, copper source and titanium source, carry out grinding treatment, obtain mixed material;

[0049] (b) performing laser excitation on the mixed material obtained in step (a) under laser irradiation and self-propagating sintering until the mixed material forms black crystals, thus obtaining the calcium copper titanate;

[0050] Wherein, the calcium source, copper source and titanium source are mixed in a molar ratio of calcium, copper and titanium elements of 1:2.8:3.5.

[0051] In step (a), the manner of grinding treatment is to grind for 6 hours at a rotational speed of 100 rad / min.

[0052] The calcium source is calcium carbonate; the copper source is copper oxide; the titanium source is titanium dioxide.

[0053] In the step (b), the laser wavelength of the laser irradiation is 800nm.

[0054] In the step (b), the process of laser irradiation is that ...

Embodiment 3

[0058] A preparation method of calcium copper titanate, comprising the steps of:

[0059] (a), after mixing calcium source, copper source and titanium source, carry out grinding treatment, obtain mixed material;

[0060] (b) performing laser excitation on the mixed material obtained in step (a) under laser irradiation and self-propagating sintering until the mixed material forms black crystals, thus obtaining the calcium copper titanate;

[0061] Wherein, the calcium source, copper source and titanium source are mixed in a molar ratio of calcium, copper and titanium elements of 1:3.5:4.6.

[0062] In step (a), the manner of grinding treatment is to grind for 2 hours at a rotational speed of 300 rad / min.

[0063] The calcium source is calcium chloride; the copper source is copper and copper oxide compounded at a molar ratio of 2:1; the titanium source is titanium dioxide.

[0064] In the step (b), the laser wavelength of the laser irradiation is 1000nm.

[0065] In the step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com