Friction nano generator based on biomembrane materials and suitable for being used in high humidity environment and preparation method and application thereof

A nano-generator and biofilm technology, applied in the direction of friction generators, etc., can solve the problems of reduced output, reduced sensitivity, cumbersome process, etc., and achieve the effects of enhanced positive charge, low price, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

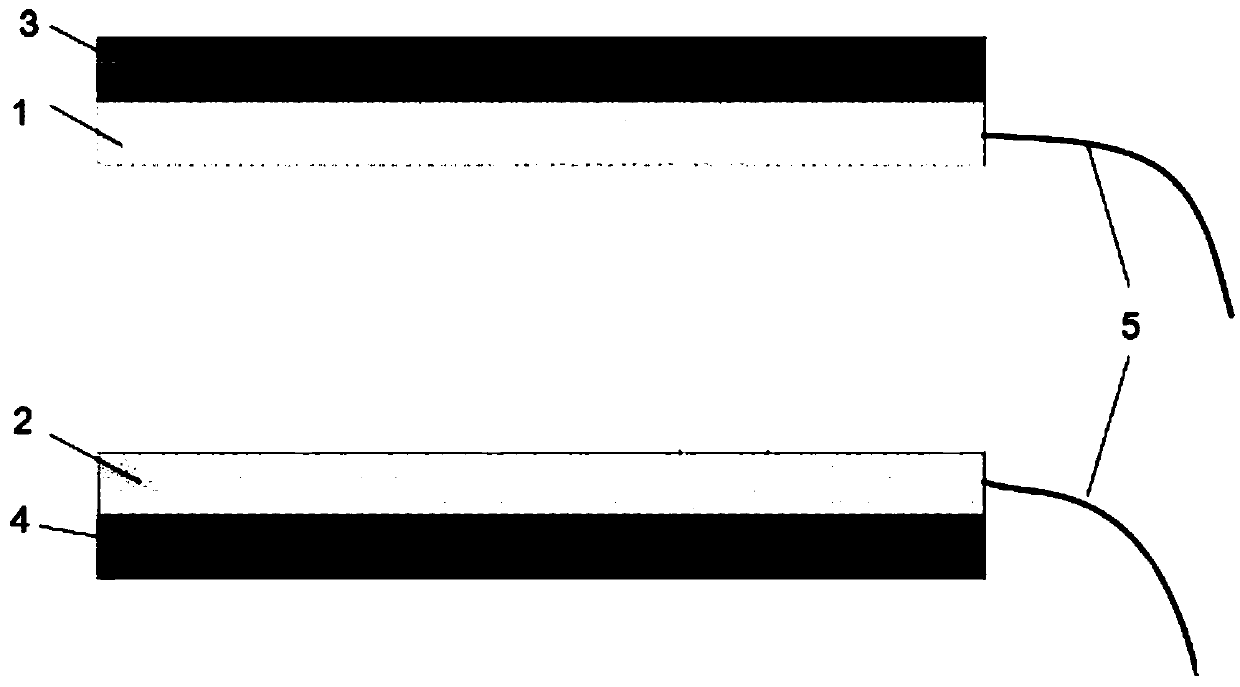

[0037] The present invention also provides a method for preparing a biofilm material-based triboelectric nanogenerator suitable for use in a high-humidity environment described in the above technical solution, comprising the following steps:

[0038] Prepare a polymer whose layered surface is modified by oxygen groups, fluorine groups or nitrogen groups, that is, a friction layer; paste the first metal electrode layer on one side of the friction layer, and lead out wires to obtain a friction layer electrode;

[0039] The polymer material is dissolved and coated to obtain an anti-friction layer; a second metal electrode layer is pasted on one side of the anti-friction layer, and a wire is drawn out to obtain an anti-friction layer electrode.

[0040] The present invention prepares a high polymer modified by oxygen groups, fluorine groups or nitrogen groups on the layered surface of the film, that is, the friction layer; pastes the first metal electrode layer on one side of the ...

Embodiment 1

[0051] A method for preparing a biofilm material-based triboelectric nanogenerator suitable for use in a high-humidity environment, comprising the following steps:

[0052] (1) After the starch granules are hydroxypropylated, gelatinize them into a film with a thickness of 0.5mm, cut into a size of "4cm x 4cm", stick copper foil on the back and lead out a wire to obtain a triboelectrode;

[0053] (2) Select PTFE as the anti-friction layer, and also cut it into a size of "4cm×4cm", with a thickness of 0.5mm, paste copper foil on the back and lead copper wires to obtain the anti-friction layer electrode;

[0054] In an environment with a humidity of 95%, the friction layer electrode and the counter friction layer electrode collide with an external force of 60N, and the friction layer and the counter friction layer realize contact and separation. The output current reaches 18μA, the output voltage reaches 380V, and after 40,000 cycles After that, the output remains stable without...

Embodiment 2

[0056] A method for preparing a biofilm material-based triboelectric nanogenerator suitable for use in a high-humidity environment, comprising the following steps:

[0057] (1) Take a cellulose film with a thickness of 0.2 mm, carry out fluorination treatment with perfluorooctyltrichlorosilane on one surface of the cellulose film, and obtain a cellulose film modified by fluorine groups on the surface, i.e. a friction layer, Cut the friction layer into a size of "4cm×4cm", paste the aluminum foil electrode on the back and lead out the copper wire to obtain the friction layer electrode;

[0058] (2) Cut the polytetrafluoroethylene with a thickness of 0.5mm into a size of "4cm x 4cm" to obtain a counter-friction layer; paste aluminum foil on the back of the counter-friction layer and lead out copper wires to obtain an anti-friction layer electrode;

[0059] Water vapor was continuously fed into the airtight box, so that the humidity continued to rise until 100%. The triboelectric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com