A kind of solid-phase extractant of p204 doped polyaniline and method for extracting light rare earths thereof

A solid phase extraction agent and light rare earth technology, applied in the direction of improving process efficiency, can solve the problems of complex separation operation, volatilization of organic solvents, secondary pollution, etc., and achieve the effect of simple separation operation, high stability and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

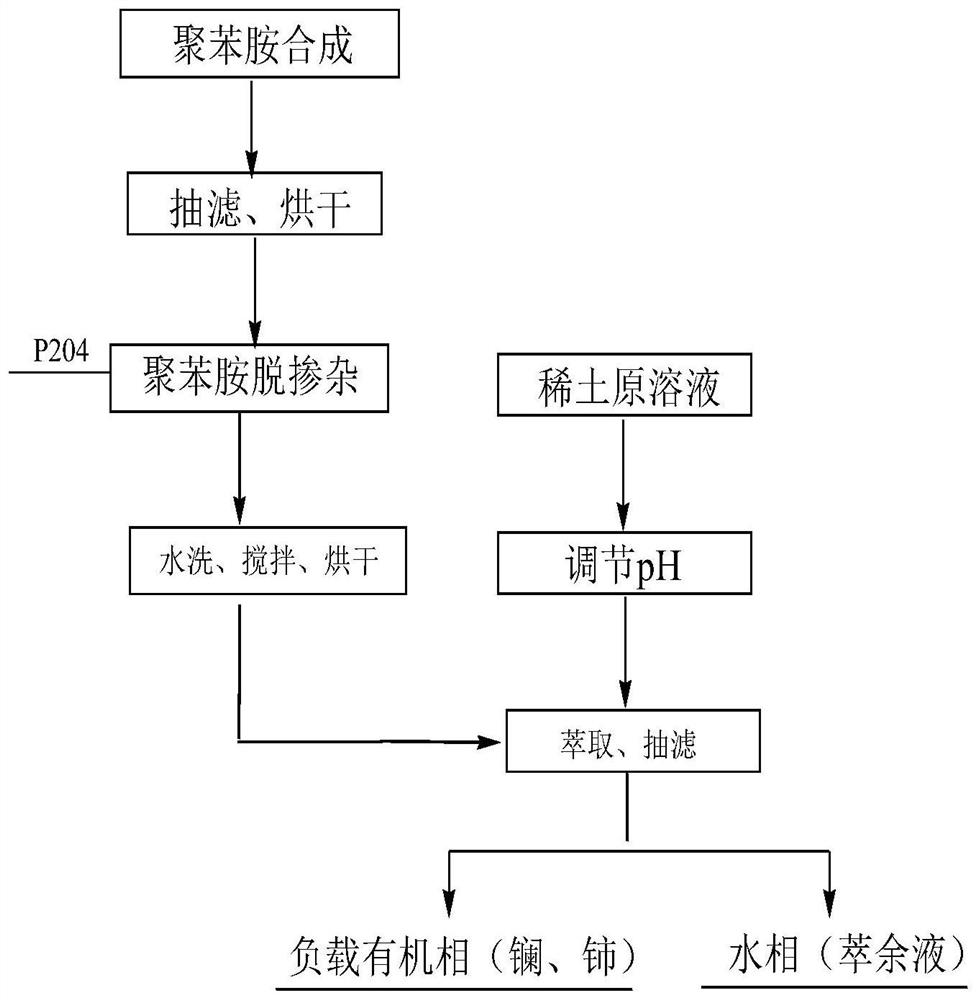

Method used

Image

Examples

Embodiment 1

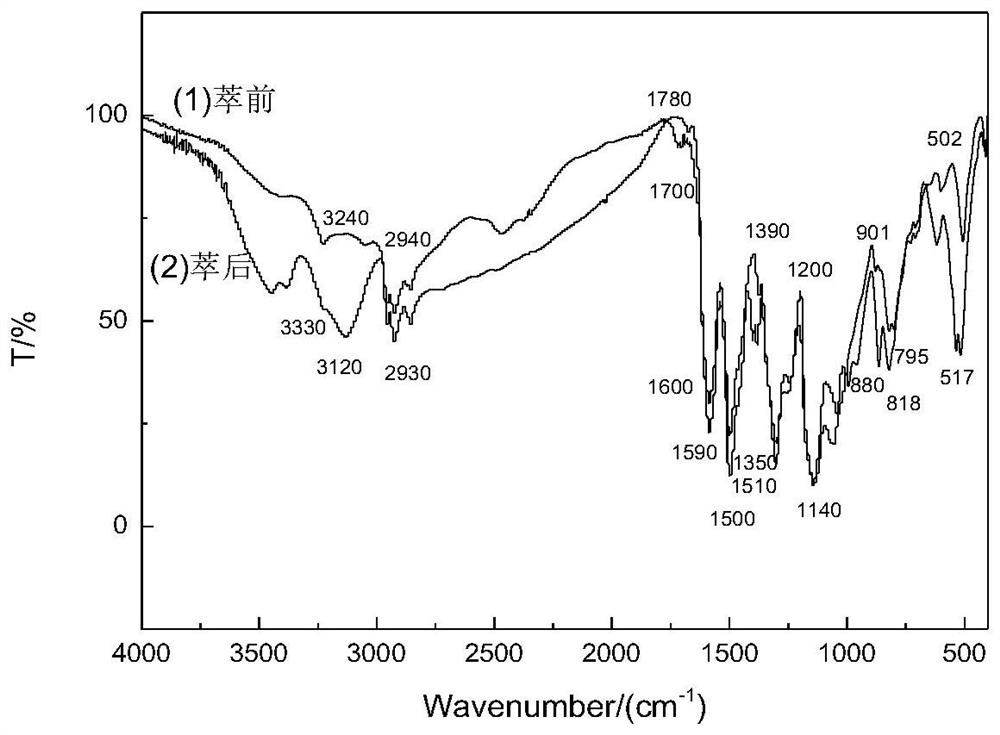

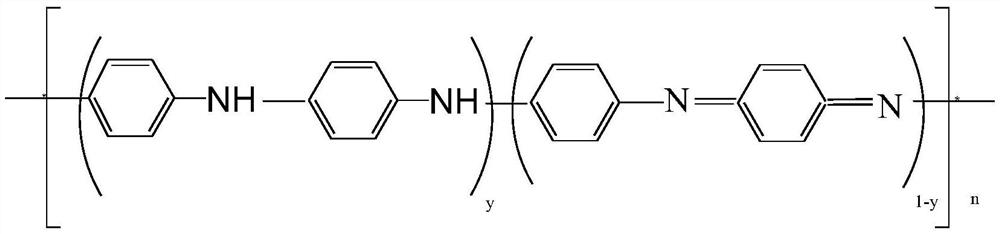

[0038] Preparation of P204-doped polyaniline solid phase extractant.

[0039]Dissolve ammonium persulfate and aniline in 1mol / L hydrochloric acid solution at a ratio of 30:1g / L to obtain ammonium persulfate solution and aniline solution. Slowly add it dropwise to the aniline solution at a ratio of 1:1, place it in a constant temperature magnetic stirrer water bath and react at room temperature for 10 hours. Wash with water several times until the filtrate is clear, put it into a drying oven at 120° C. and dry until the quality is constant to obtain polyaniline.

[0040] Slowly add the above-mentioned polyaniline into the alkali solution during the stirring process, the ratio between the polyaniline and the alkali solution is 1:4g / mL, the alkali solution used in this example is 2mol / L NaOH aqueous solution, and it is subjected to dedoping reaction , washed with water, and dried to obtain intrinsic polyaniline. The intrinsic polyaniline and P204 were doped with the ratio of in...

Embodiment 2

[0044] Preparation of P204-doped polyaniline solid phase extractant. Firstly, intrinsic state polyaniline was prepared, and the preparation method was the same as that in Example 1. The intrinsic polyaniline and P204 were doped with the ratio of intrinsic polyaniline and P204 being 10:1 g / L to obtain a solid phase extractant.

[0045] The rare earth solution prepared with lanthanum chloride-heptahydrate compound is the raw material liquid, which is the raw material liquid of this embodiment, La 3+ The concentration of the concentration is 0.01mol / L, adopts mineral acid (HCl) to adjust the solution pH to be 4;

[0046] The rare earth raw material liquid is mixed with a solid extractant for extraction, the amount of solid extractant is 0.3g, the amount of rare earth raw material liquid is 10ml, the rotation speed is 200r / min, the extraction time is 30min, and the extraction temperature is 25°C. After the extraction is completed, the raffinate and the solid-phase extractant are...

Embodiment 3

[0048] Preparation of P204-doped polyaniline solid phase extractant. Firstly, intrinsic state polyaniline was prepared, and the preparation method was the same as that in Example 1. Mix intrinsic polyaniline with P204, the ratio of intrinsic polyaniline to P204 is 10:1g / L, to obtain solid phase extractant.

[0049] Rare earth solution prepared with lanthanum chloride-heptahydrate compound as raw material solution, La 3+ The concentration is 0.01mol / L, adopts mineral acid (sulfuric acid) to regulate solution pH to be 5;

[0050] The rare earth raw material liquid is mixed with a solid extractant for extraction, the dose of solid phase extraction is 0.5g, the amount of rare earth raw material liquid is 10ml, the rotation speed is 400r / min, the extraction time is 30min, and the extraction temperature is 25°C. After the extraction is completed, the raffinate and the solid-phase extractant are separated by suction filtration through a suction filtration device. The rare earth co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com