Flexible conductive film with gas sensitivity performance and application thereof

A flexible conductive, gas-sensitive technology, applied to the conductive layer on the insulating carrier, organic material conductors, non-metallic conductors, etc., can solve problems such as limited applications, improve gas sensitivity, ensure food safety and human health, and facilitate Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Cut the PET film with a thickness of 0.1mm into a surface area of 0.49cm 2 3-4 mg of flake-shaped molybdenum trioxide is coated on it, the preferred size of molybdenum trioxide is 5-10 nm in thickness, 20-50 nm in width, and 3-5 μm in length, and the ratio of aniline to molybdenum trioxide is 1 :10, 1:3, 10:1 mixed, under the catalysis of ammonium persulfate in acidic solution, aniline is attached to the acidic active sites on the surface of molybdenum trioxide to polymerize to generate protonated polyaniline, and a flexible conductive film is obtained. The electron microscope images of the flexible conductive film are as follows: figure 2 Shown in Figures a, b, and c.

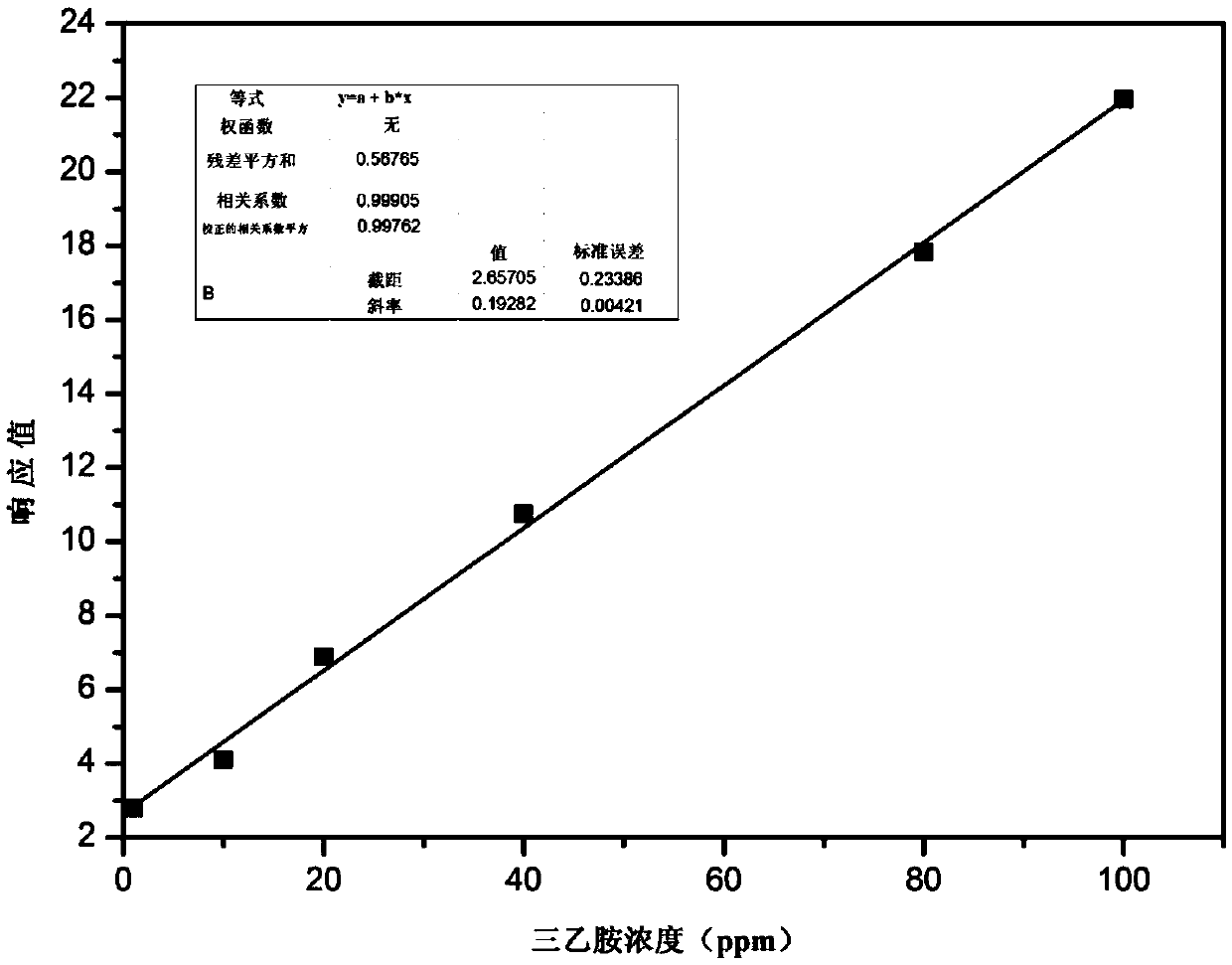

[0036] Gained flexible conductive film is tested the triethylamine concentration in the scope of 0ppm~100ppm at room temperature, and the minimum monitoring concentration of triethylamine is 0.5ppm and its response value is 1.2, and when 1ppm, response value is 2.8 (response value is flexible conduc...

Embodiment 2

[0038] Cut the PET film with a thickness of 0.1mm into a surface area of 0.49cm 2 0.5-1.5 mg of rod-shaped tungsten trioxide is coated on it. The preferred size of tungsten trioxide is 10-20 nm in diameter and 1.5-2 μm in length. Aniline and tungsten trioxide are mixed at a weight ratio of 1:2. Under the catalysis of ammonium persulfate, aniline adhered to the surface of tungsten trioxide and polymerized into protonated polyaniline to prepare a flexible conductive film.

[0039] Gained flexible conductive film is tested at room temperature to the response value of 100ppm triethylamine, ethylenediamine, ammonia, ethanol, acetone, test result is as follows Figure 4 .

Embodiment 3

[0041] Use a PET film with a thickness of 0.1mm and cut it into a surface area of 0.49cm 2 A square film of 0.5-1.5 mg, a hollow tubular tin oxide with a wall thickness of 1-10 nm and a length greater than 1 μm is coated on it, and pyrrole and tin oxide are mixed at a weight ratio of 1:2, and ammonium persulfate is mixed in an acidic solution. Under the catalysis, pyrrole is polymerized on the surface of hollow tubular tin oxide to form polypyrrole, and a flexible conductive film is prepared.

[0042] Gained flexible conductive film is tested ammonia gas concentration data at room temperature as Figure 5 , to monitor the change of ammonia concentration in the environment during the petrochemical production process by monitoring the change of the resistance of the flexible conductive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com