Preparation method of magnesium alloy surface anticorrosive coating

An anti-corrosion coating, magnesium alloy technology, applied in metal material coating process, coating, melting spray plating and other directions, can solve the problems of low corrosion resistance, can not meet the requirements of use, low hardness of aluminum coating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing a magnesium alloy surface anticorrosion coating, comprising the following steps:

[0022] (1) Pretreating the magnesium alloy matrix;

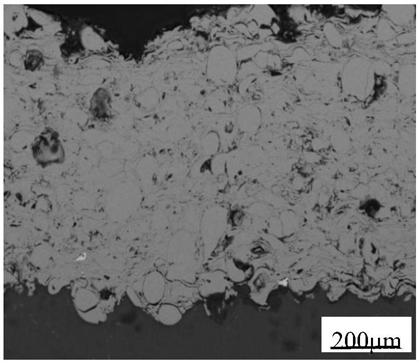

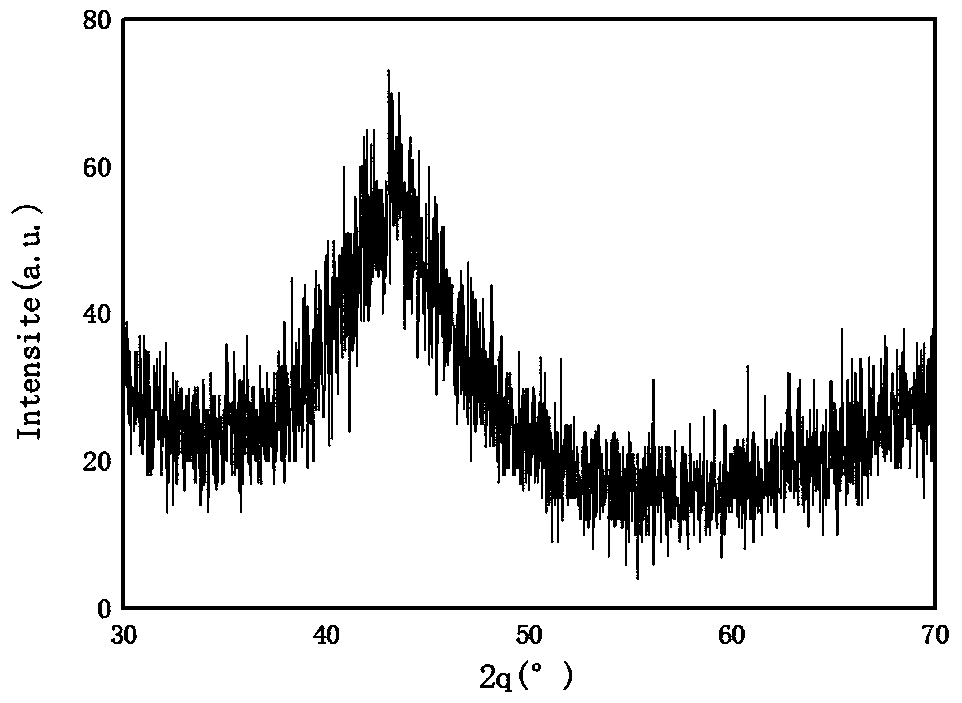

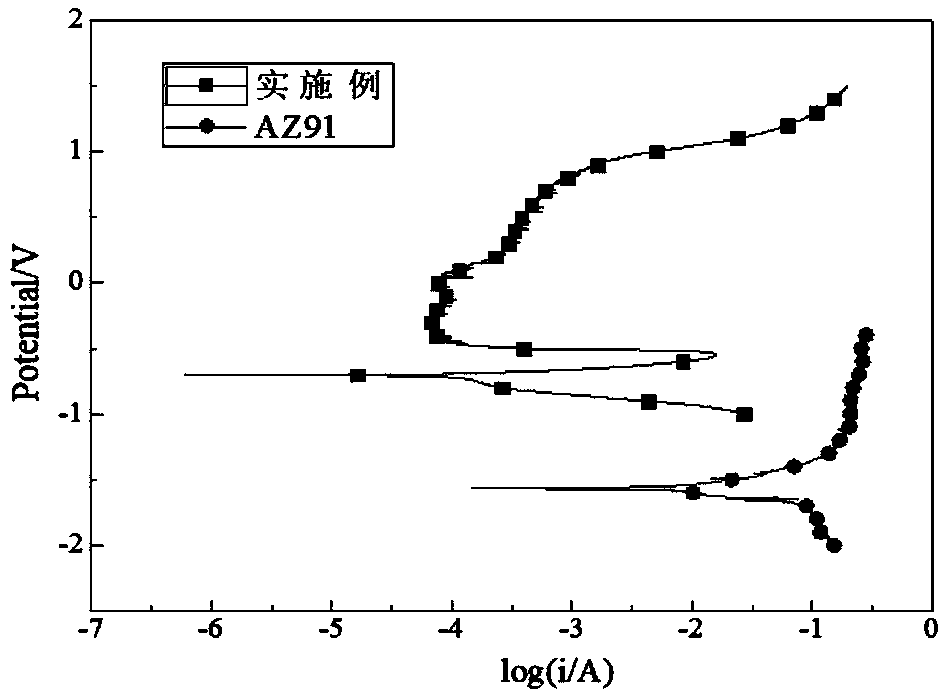

[0023] (2) heating up the magnesium alloy substrate pretreated in the step (1) to 60-100°C, then maintaining the temperature of the magnesium alloy substrate at 60-100°C, using iron-based amorphous alloy particles as the coating to be sprayed, Supersonic flame spraying is carried out on the surface of the magnesium alloy substrate, and an iron-based amorphous alloy anti-corrosion coating is obtained on the surface of the magnesium alloy substrate.

[0024] In the invention, the magnesium alloy substrate is pretreated.

[0025] In the present invention, the pretreatment preferably includes cleaning, sandblasting and grinding performed in sequence. In the present invention, the cleaning in the pretreatment process can remove the oil stain on the surface of the magnesium alloy substrate, and ...

Embodiment 1

[0041] (1) Place the AZ91 magnesium alloy substrate in ethanol for ultrasonic cleaning;

[0042] (2) 1 hour before spraying, the AZ91 magnesium alloy substrate after ultrasonic cleaning was subjected to dry sandblasting treatment, the abrasive used in the sandblasting treatment was 20# white corundum sand, and the pressure of the sandblasting treatment was 0.65MPa. The speed of sandblasting is 0.5cm / s, and the time of sandblasting is 5min;

[0043] (3) Use a steel brush to polish the surface of the AZ91 magnesium alloy substrate after dry blasting, remove particulate matter, and obtain a clean AZ91 magnesium alloy substrate;

[0044](4) Drying 250-300 mesh iron-based amorphous alloy particles under vacuum conditions at 100° C. for 1 hour to obtain dry iron-based amorphous alloy particles;

[0045] (5) fixing the AZ91 magnesium alloy substrate obtained in step (3); putting the dry iron-based amorphous alloy particles obtained in step (4) into supersonic flame spraying equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com