a porous co 3 o 4 / al 2 sio 5 Low-density wave-absorbing composite phase ceramics and preparation method thereof

A composite ceramic and low-density technology, which is applied in the field of porous Co3O4/Al2SiO5 low-density wave-absorbing type composite ceramics and its preparation, can solve the problems of limited application of wave-absorbing materials, complex preparation process, and long preparation cycle, and achieve improved Interface polarization and dielectric loss capability, improved absorbing performance, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

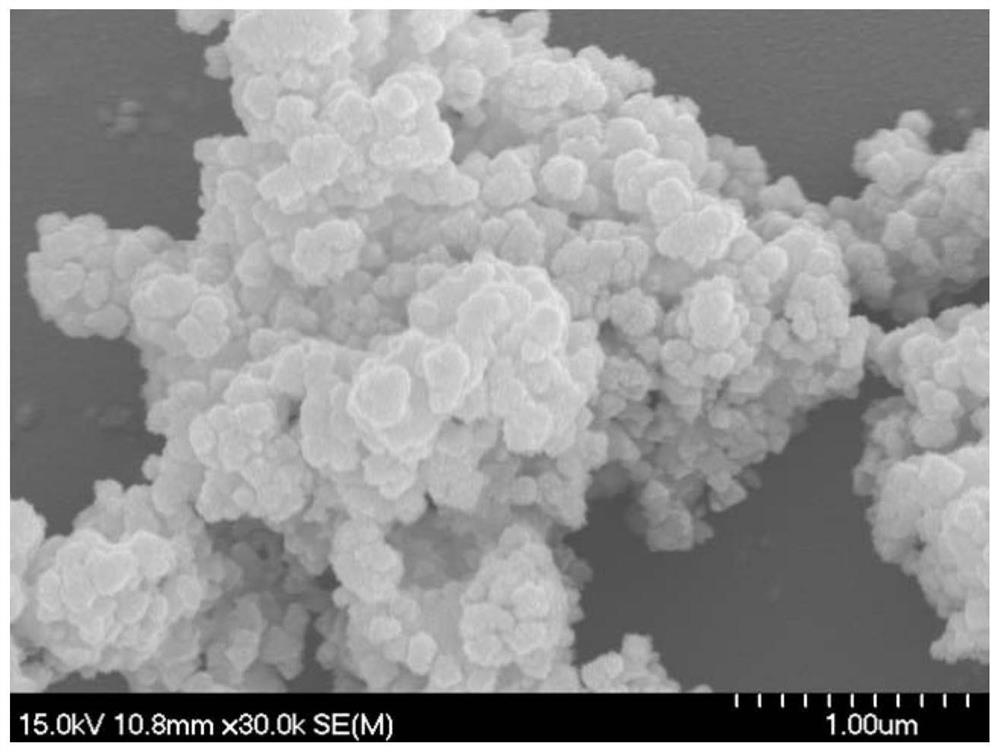

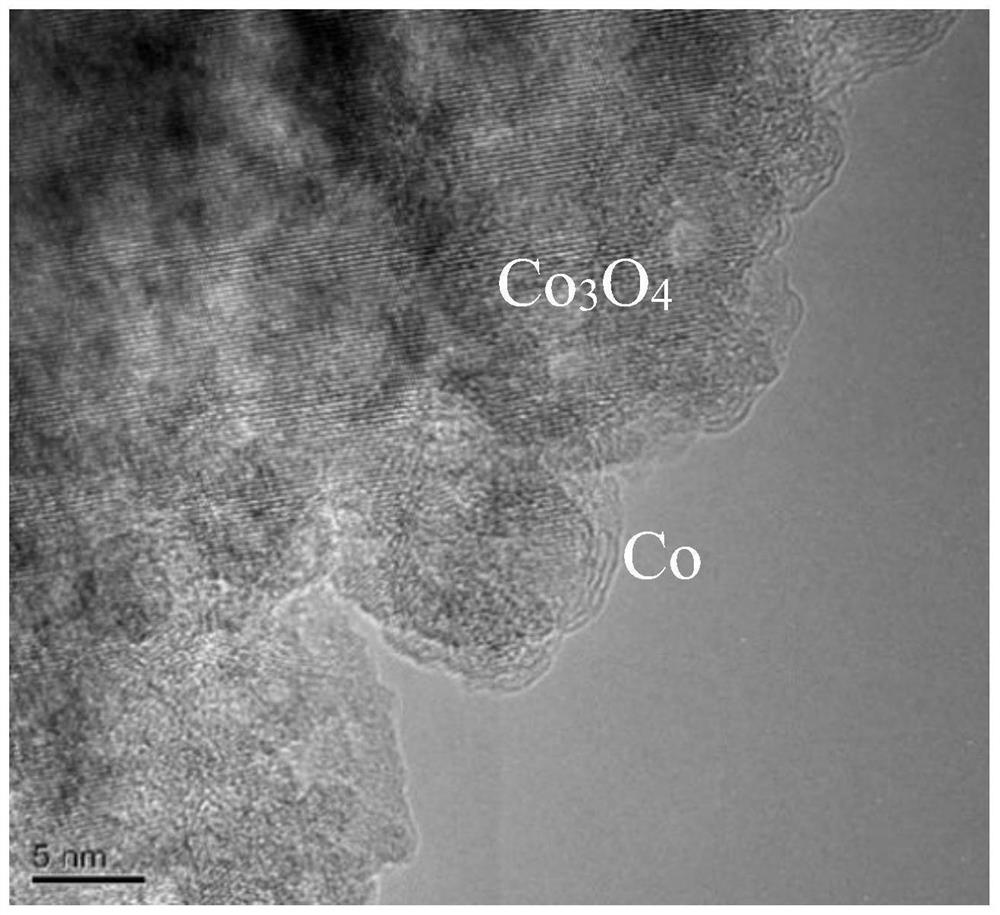

[0041] 1) Add cobalt acetate tetrahydrate and monoethanolamine into absolute ethanol at a molar ratio of 1:1, the molar concentration of cobalt acetate is 0.1mol / L, and stir magnetically for 1 hour at 30°C to obtain a precursor solution;

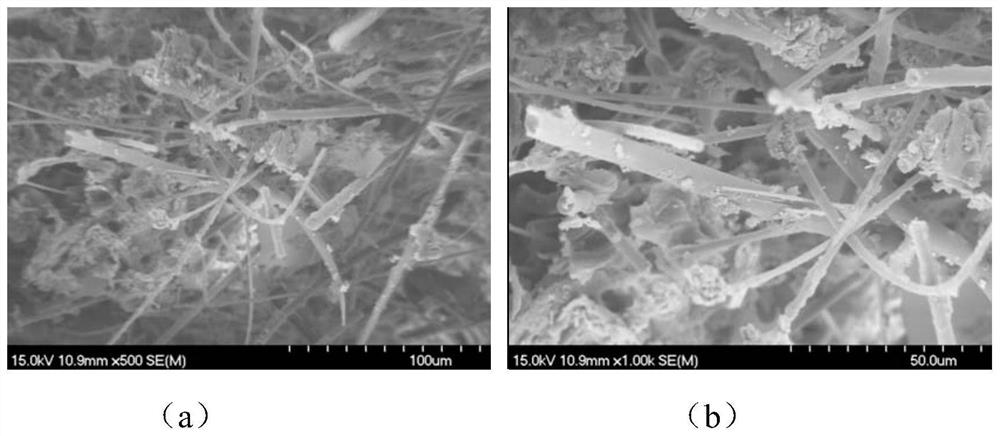

[0042] 2) Cut the porous Al into the desired size 2 SiO 5 Immerse the ceramic fiber board into the solution in step 1) for 0.5h under vacuum impregnation, the vacuum degree is less than 50Pa, and prepare a preform. The prepared preform is dried at 100°C for 0.5h, and then heat-treated at 200°C for 0.5h. The heating rate is at 1°C / min, one-time impregnated porous Co 3 o 4 / Al 2 SiO 5 For composite ceramics, the above process does not require a protective atmosphere and is carried out in an air environment;

[0043] 3) Immerse the multiphase ceramics in step 2) into the solution of step 1), and perform drying and heat treatment according to step 2), and cycle 15 times in this way, the Co in the multiphase ceramics 3 o 4 The content is 15%...

Embodiment 2

[0047] 1) Add cobalt acetate tetrahydrate and monoethanolamine into absolute ethanol at a molar ratio of 1:1, the molar concentration of cobalt acetate is 0.2mol / L, and stir magnetically for 1 hour at 30°C to obtain a precursor solution;

[0048] 2) Cut the porous Al into the desired size 2 SiO 5 Immerse the ceramic fiber board into the solution in step 1), and immerse it at a high pressure of 1Mpa for 0.5h to prepare a preform, dry the prepared preform at 100°C for 0.5h, and then heat treat it at 300°C for 1h, with a heating rate of 2°C / min, to obtain a porous Co impregnated once 3 o 4 / Al 2 SiO 5 For composite ceramics, the above process does not require a protective atmosphere and is carried out in an air environment;

[0049] 3) Immerse the multiphase ceramics in step 2) into the solution of step 1), and perform drying and heat treatment according to step 2), and cycle 12 times in this way, the Co in the multiphase ceramics 3 o 4 The content is 27.5%;

[0050] 4) ...

Embodiment 3

[0053] 1) Add cobalt acetate tetrahydrate and monoethanolamine into absolute ethanol at a molar ratio of 1:1, the molar concentration of cobalt acetate is 0.3mol / L, and stir magnetically at 30°C for 1 hour to obtain a precursor solution;

[0054] 2) Cut the porous Al into the desired size 2 SiO 5 Immerse the ceramic fiber board into the solution in step 1), and immerse it at a high pressure of 5MPa for 0.5h to prepare a preform, dry the prepared preform at 100°C for 0.5h, and then heat treat it at 300°C for 0.5h, with a heating rate of 2°C / min, get impregnated porous Co once 3 o 4 / Al 2 SiO 5 For composite ceramics, the above process does not require a protective atmosphere and is carried out in an air environment;

[0055] 3) Immerse the multiphase ceramics in step 2) into the solution of step 1), and perform drying and heat treatment according to step 2), and cycle 10 times in this way, the Co in the multiphase ceramics 3 o 4 The content is 42.5%;

[0056] 4) Place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com