High temperature resistant boron nitride-cerium feldspar ceramic matrix composite material and preparation method thereof

A composite material, strontium feldspar technology, applied in the field of high temperature resistant boron nitride-strontium feldspar ceramic matrix composite material and its preparation, can solve the problems of low density, low thermal expansion coefficient, limited application of strontium feldspar, poor processability, etc. Achieve high density, inhibit abnormal grain growth, good dielectric and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

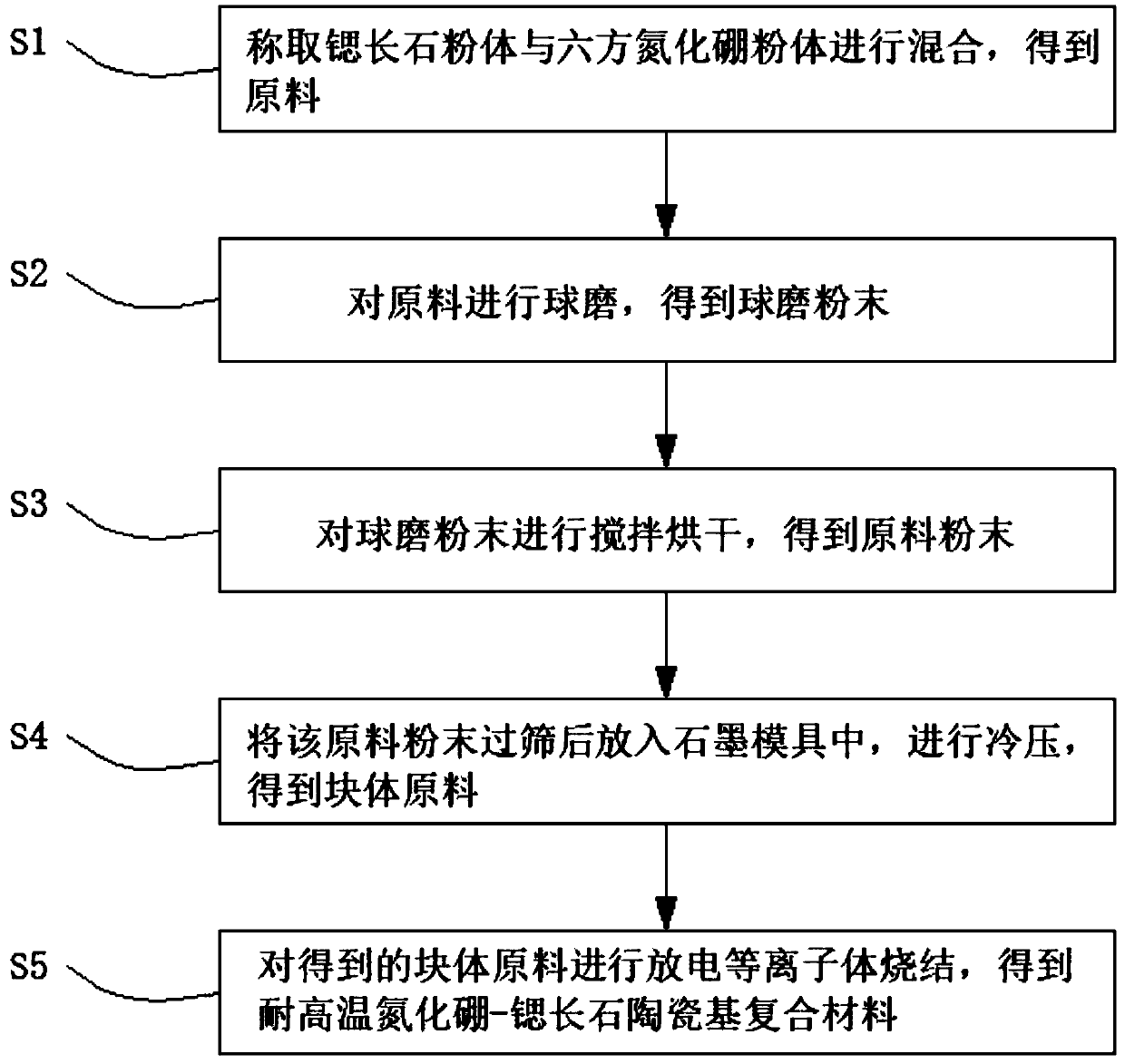

[0032] In order to solve the problem of poor machinability of strontium feldspar, the present invention provides a high temperature resistant boron nitride-strontium feldspar ceramic matrix composite material and the preparation method of the composite material, see figure 1 As shown, wherein the preparation method of high temperature resistant boron nitride-strontium feldspar ceramic matrix composite material comprises the following steps:

[0033] S1: weighing strontium feldspar powder and hexagonal boron nitride powder and mixing to obtain raw materials;

[0034] S2: ball milling the raw materials to obtain ball milling powder;

[0035] S3: stirring and drying the ball mill powder to obtain raw material powder;

[0036] S4: Put the raw material powder into a graphite mold after sieving, and perform cold pressing to obtain a block raw material;

[0037] S5: performing discharge plasma sintering on the obtained bulk raw material to obtain a high temperature resistant boron ...

Embodiment 1

[0060] This embodiment provides a method for preparing a high temperature resistant boron nitride-strontium feldspar ceramic matrix composite material, the method comprising:

[0061] S1: Weighing 77.35 g of strontium feldspar powder with a particle size of 200 mesh and 13.68 g of hexagonal boron nitride powder with a particle size of 100 mesh and a purity of 99 wt%, and mixing them to obtain raw materials;

[0062] S2: placing the obtained raw materials in a polytetrafluoroethylene ball milling tank, using alumina balls as a ball milling medium, adding absolute ethanol to carry out wet ball milling for 24 hours to obtain a ball milling powder;

[0063] S3: stirring and drying the ball-milled powder at 60° C. for 4 hours to obtain raw material powder;

[0064] S4: Pass the raw material powder through a 100-mesh sieve, put it into a graphite mold, and cold press it at a pressure of 30 MPa for 3 minutes to obtain a block raw material;

Embodiment 2

[0077] This embodiment provides a method for preparing a high temperature resistant boron nitride-strontium feldspar ceramic matrix composite material, the method comprising:

[0078] S1: 56.4 g of strontium feldspar powder with a particle size of 200 mesh was weighed and mixed with 37.6 g of hexagonal boron nitride powder with a particle size of 100 mesh and a purity of 99 wt%, to obtain raw materials;

[0079] S2: placing the obtained raw materials in a polytetrafluoroethylene ball milling tank, using alumina balls as a ball milling medium, adding absolute ethanol to carry out wet ball milling for 12 hours to obtain a ball milling powder;

[0080] S3: stirring and drying the ball-milled powder at 60° C. for 6 hours to obtain raw material powder;

[0081] S4: Put the raw material powder through a 100-mesh sieve and put it into a graphite mold with an inner diameter of 20 mm and a boron nitride-coated inner wall, and cold press it at a pressure of 15 MPa for 5 minutes to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com