Modified epoxide resin and preparing method thereof and high-throwing-power cathode electrophoretic coating

A technology of epoxy resin and epoxy resin emulsion, which is applied in the direction of electrophoretic coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of not being able to satisfy the uniform coating ability, achieve good application prospects, and improve durability Performance such as corrosion, effects of excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0040] Embodiment 1~3, modified epoxy resin of the present invention and preparation thereof

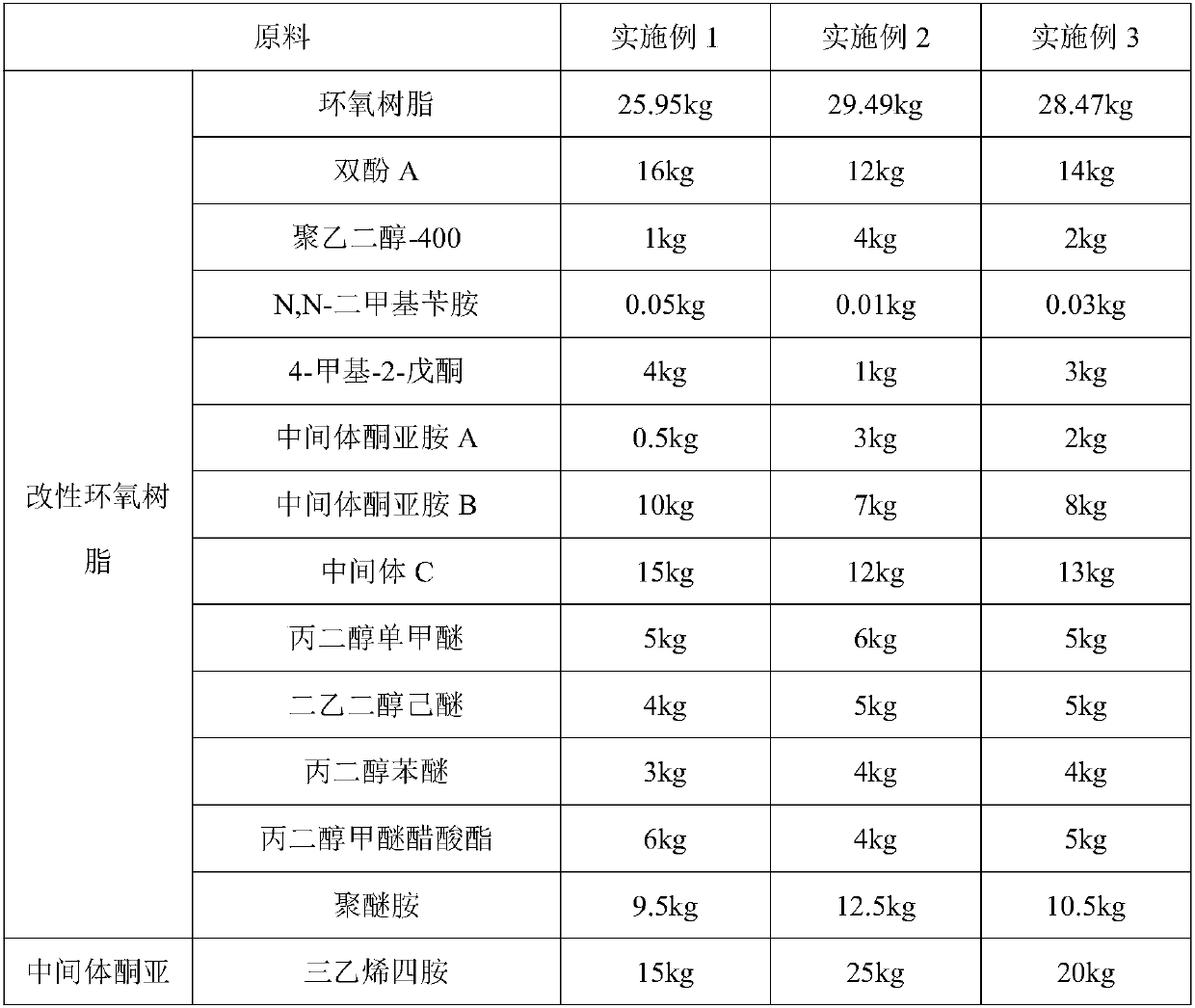

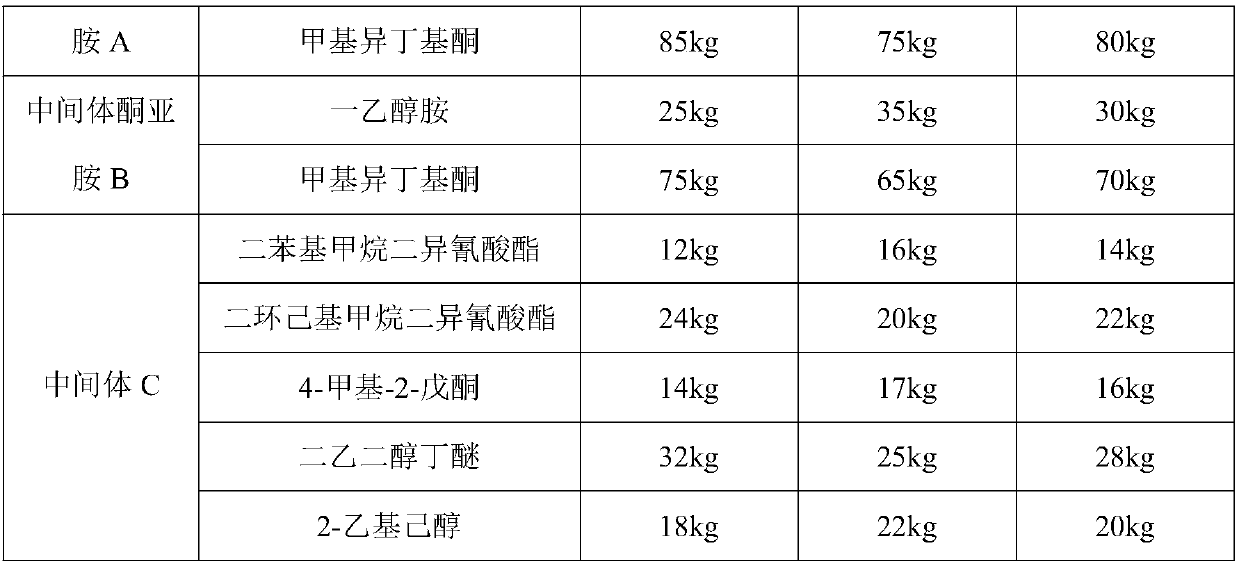

[0041] The formulations of the modified epoxy resins of Examples 1 to 3 of the present invention are shown in Table 1 below.

[0042] The formula of table 1 embodiment 1~3 modified epoxy resin

[0043]

[0044]

[0045] The epoxy resin is a bisphenol A type epoxy resin with an epoxy equivalent of 184-190 g / eq and a viscosity of 12000-15000 cps / 25°C. The specific model is epoxy resin 128E, which is a commercially available product.

[0046] The preparation method of embodiment 1~3 modified epoxy resin is as follows:

[0047] A1. Preparation of intermediate ketimine A: Add triethylenetetramine and methyl isobutyl ketone in the formula amount to the reactor, react at 160-180°C for reflux for 12 hours, keep at 160-180°C, and 80 ± 10) kPa negative pressure under reflux dehydration 24h, made the intermediate ketimine A;

[0048] A2. Preparation of the intermediate ketimine B: add ...

Embodiment 4~6

[0055] Embodiments 4-6, cathodic electrophoretic coating with high throwing power of the present invention and its preparation

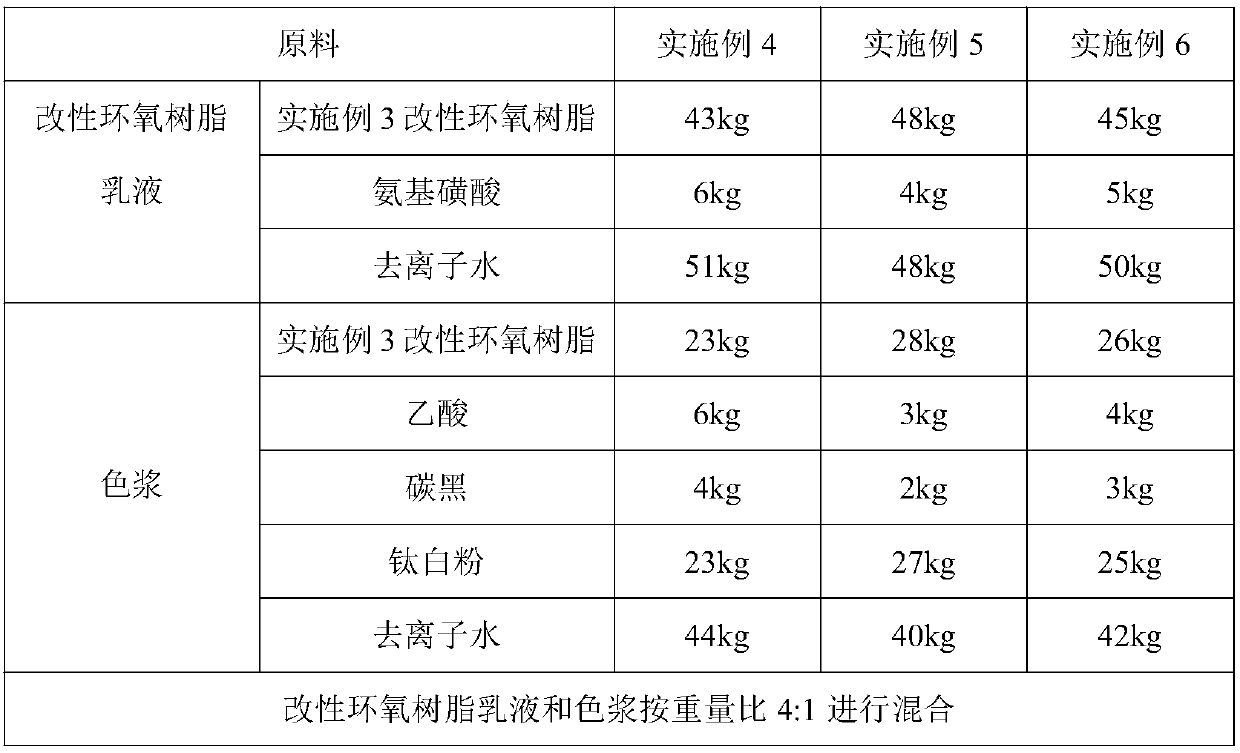

[0056] The formulations of cathodic electrophoretic coatings with high throwing power in Examples 4 to 6 of the present invention are shown in Table 2 below.

[0057] The formula of table 2 embodiment 4~6 cathodic electrophoretic coating with high throwing power

[0058]

[0059] The preparation method of embodiment 4~6 cathodic electrophoretic paint with high throwing power is as follows:

[0060] S1. Preparation of modified epoxy resin emulsion: add the modified epoxy resin in the amount of formula into the reactor, and add the aminosulfonic acid and deionized water in the amount of formula in the stirring state at a temperature of 50-60°C, and keep warm After 4 hours, add deionized water for emulsification, lower the temperature to 45°C to 50°C, and extract the solvent for 5 hours under a negative pressure of -(80±10)kPa to prepare a modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com