Graphene composite nano-Fe3O4 radar wave absorption material and preparation method thereof

A technology of graphene composite and absorbing materials, which is applied in the field of graphene composite nano Fe3O4 radar wave absorbing materials and graphene composite nano Fe3O4 radar wave absorbing materials, which can solve the problems of microwave absorption performance, wide application, high conductivity and electromagnetic The parameters cannot meet the impedance matching and other problems, and it is suitable for large-scale mass production, the preparation method is simple and easy to operate, and the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

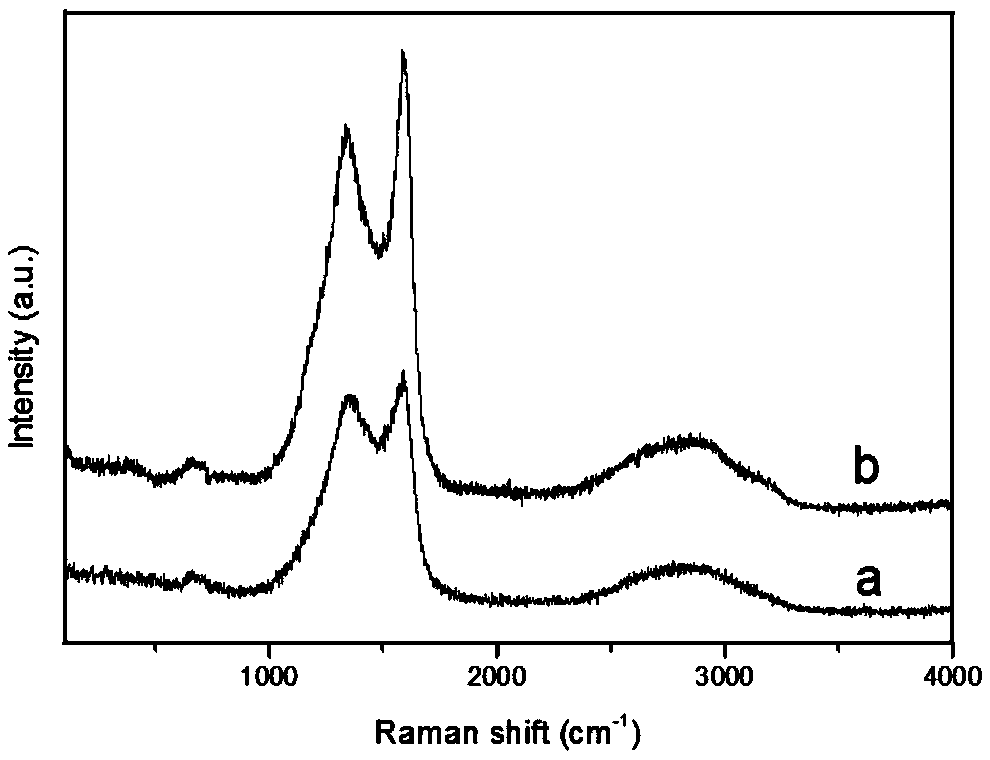

Image

Examples

preparation example Construction

[0040] The present invention proposes a graphene composite nano-Fe 3 o 4 The preparation method of the radar wave absorbing material. The preparation method comprises the following steps:

[0041] dissolving the ferrous salt and the ferric salt in water, and stirring to obtain an iron salt solution;

[0042] Dispersing the reduced graphene oxide solution in an organic alcohol solvent, stirring to obtain a dispersion;

[0043] mixing the iron salt solution and the dispersion, and adding a precipitating agent to obtain a mixed solution;

[0044] The mixed solution is moved into a reaction kettle, and heated to obtain a reaction product;

[0045] The obtained reaction product is separated, washed and dried to obtain graphene composite nano-Fe 3 o 4 ;

[0046] The graphene composite nano-Fe 3 o 4 Grinding and filling into the matrix to obtain the graphene composite nano-Fe 3 o 4 Radar absorbing material.

[0047] Specifically, first, a certain amount of ferrous salt and ...

Embodiment 1

[0071] First, weigh 9.73g FeCl 3 ·6H 2 O and 5.56 g FeSO 4 ·7H 2 O was dissolved in 10mL of ultrapure water, then 4.8g of urea was added, and stirred to obtain a uniform solution. Take 16mL of RGO solution with a concentration of 4mg / mL and disperse it in a mixed solution of 23mL of ethylene glycol and 1mL of polyethylene glycol-400, stir and ultrasonically obtain the dispersion for 20min and pour it into the homogeneous solution obtained above, and mix and stir for a certain time. After a period of time, it was slowly transferred to a 100mL polytetrafluoroethylene-lined stainless steel autoclave, placed in a constant temperature drying oven, heated and reacted at 160°C for 5h, and then naturally cooled to room temperature after taking out the autoclave. The reaction product obtained after the reaction is a black solution, which is magnetically separated and washed 3-4 times with a mixture of ethanol and ultrapure water at a volume ratio of 1:1, and then placed in a vacuum ...

Embodiment 2

[0073] First, weigh 9.73g FeCl 3 ·6H 2 O and 5.56 g FeSO 4 ·7H 2 O was dissolved in 10mL of ultrapure water, then 4.8g of urea was added, and stirred to obtain a uniform solution. Take 16mL of RGO solution with a concentration of 34mg / mL and disperse it in a mixed solution of 23mL of ethylene glycol and 1mL of polyethylene glycol-400, stir and ultrasonically obtain the dispersion for 20min and pour it into the homogeneous solution obtained above, mix and stir for a certain time. After a period of time, it was slowly transferred to a 100mL polytetrafluoroethylene-lined stainless steel autoclave, placed in a constant temperature drying oven, heated and reacted at 160°C for 5h, and then naturally cooled to room temperature after taking out the autoclave. The reaction product obtained after the reaction is a black solution, which is magnetically separated and washed 3-4 times with a mixture of ethanol and ultrapure water at a volume ratio of 1:1, and then placed in a vacuum dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum reflection loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com