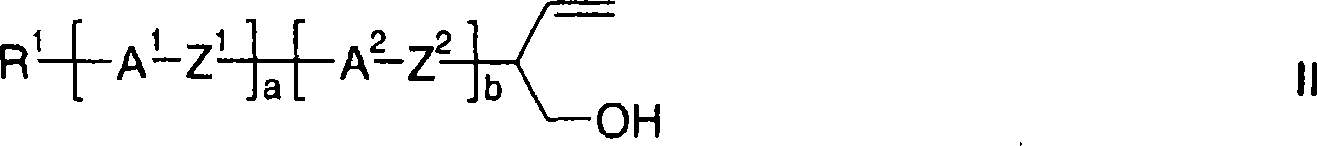

Method for producing tetrahydropyran derivatives

A technology for tetrahydropyran derivatives and compounds, applied in the direction of organic chemistry, etc., can solve the problems of low convergence and divergence, and achieve the effects of high chemical and stereoselectivity, simple method and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0181]

[0182] No. 3a,b - Table 1 A1 A2

[0183] 156 g (0.487 mol) of 4-bromo-2-(4-bromophenyl)tetrahydropyran (mixture of isomers 2,4-cis:2,4-trans) of number 3a,b in Table 1 formula = 84:16) and 87.2 ml (0.73 mol) of 1,5-diazabicyclo[4.3.0]non-5-ene (DBN) in 330 ml of toluene with stirring at reflux for 3 hours, where During this time a suspension was formed. After cooling, the mixture was adjusted to pH 3 with 400 ml of water and dilute sulfuric acid and mixed vigorously. The organic phase was separated off with water and NaHCO 3 The solution was washed, filtered through silica gel and evaporated to give 105 g of a product mixture comprising A1 and A2 in a ratio of 65:35.

Embodiment B

[0185]

[0186] No. 2 - Table 3 B1

[0187] 49.7 g (0.15 mol) of isomer-pure 4-bromo-2-(4-bromophenyl)-5-methyltetrahydropyran numbered 2 in Table 3 were combined with 27.8 g (0.225 mol) of DBN was stirred in 200 ml of toluene at reflux for 4 h. The mixture was then cooled to 0°C and the salt precipitate was removed by filtration, and the filtrate was concentrated and filtered through silica gel using toluene / heptane (1:1). The filtrate was evaporated and the residue was crystallized from ethanol. The only isomer obtained was 4,5-dihydro-5-methyltetrahydropyran B1; yield (not optimized): 15.6 g (73%)

Embodiment C

[0189]

[0190] No. 3 - Table 3 C1

[0191] Similar to Example B, the tetrahydropyran derivative No. 3 in Table 3 (isomer mixture 2,4-cis:2,4-trans=85:15; 32.9 g, 0.107 mol) gave C1 , yield (without optimization): 89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com