Carbon dioxide capturing agent and application thereof

A carbon dioxide and collector technology, applied in alkali metal oxides/hydroxides, reagents, inorganic chemistry, etc., can solve the problems of high cost, complex preparation process, low capture efficiency, etc., and achieve low cost, wide range of sources, The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

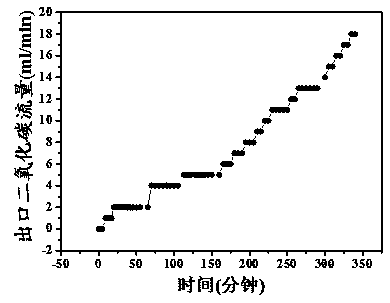

Image

Examples

Embodiment 1

[0026] 1) Preparation of carbon dioxide capture agent:

[0027] Select waste concrete from construction waste, use a small hammer crusher for primary crushing and control the output particle size to ≤10mm, put the waste concrete after primary crushing into a corundum crucible and put it into a box-type resistance furnace at different temperature systems Pre-burn at 500°C; take it out after the furnace temperature drops below 100°C, and then crush and separate it in an electromagnetic vibrating pulverizer after cooling to room temperature, and control the vibrating pulverization time to 3~ After shaking for 10 seconds, pour it into a 60-325-mesh square-hole sieve, and separate the coarse aggregate and fine powder in the waste concrete through sieving. The smaller waste concrete fine powder passes through the sieve holes to become the undersize, and the fine particles that pass through the sieve are collected to obtain the hardened gel.

[0028] Since the above-mentioned preparat...

Embodiment 2

[0034] 1) Preparation of carbon dioxide capture agent:

[0035] Select waste concrete from construction waste, use a small hammer crusher for primary crushing and control the output particle size to ≤10mm, put the waste concrete after primary crushing into a corundum crucible and put it into a box-type resistance furnace at different temperature systems Pre-burn at 600°C; take it out after the furnace temperature drops below 100°C, and crush and separate it in an electromagnetic vibrating pulverizer after cooling to room temperature, and control the vibrating pulverization time to 3 ~ After shaking for 10 seconds, pour it into a 60-325-mesh square-hole sieve, and separate the coarse aggregate and fine powder in the waste concrete through sieving. The smaller waste concrete fine powder passes through the sieve holes to become the undersize, and the fine particles that pass through the sieve are collected to obtain the hardened gel.

[0036] Since the above-mentioned preparatio...

Embodiment 3

[0044] 1) Preparation of carbon dioxide capture agent:

[0045] Select waste concrete from construction waste, use a small hammer crusher for primary crushing and control the output particle size to ≤10mm, put the waste concrete after primary crushing into a corundum crucible and put it into a box-type resistance furnace at different temperature systems Pre-burning at a temperature of 700°C; take it out after the furnace temperature drops below 100°C, and crush and separate it in an electromagnetic vibrating pulverizer after cooling to room temperature, and control the vibrating pulverization time to 3 ~ After shaking for 10 seconds, pour it into a 60-325-mesh square-hole sieve, and separate the coarse aggregate and fine powder in the waste concrete through sieving. The smaller waste concrete fine powder passes through the sieve holes to become the undersize, and the fine particles that pass through the sieve are collected to obtain the hardened gel.

[0046] Since the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com