Method for screening riboflavin in food and medicine by connecting high-performance thin-layer chromatography with surface-enhanced Raman spectrum

A high-efficiency thin-layer chromatography and surface-enhanced Raman technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as unsuitable for screening a large number of samples, high processing requirements, and instrument damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of riboflavin standard solution: Use ammonia water with a mass concentration of 1% as a solvent, dilute with methanol to prepare a riboflavin standard solution with a concentration of 0.01mg / mL;

[0023] (2) Preparation of nano-silver colloid: silver colloid was prepared according to the classic method of synthesizing nano-silver colloid with sodium borohydride as reducing agent. Take 5mL of the original silver colloid and centrifuge (4000r / min, 10min), discard 4.5mL of the supernatant, place 0.5mL of the remaining liquid on a mixer and shake it for 1min to resuspend it, and obtain a 10-fold concentrated nano Silver colloid.

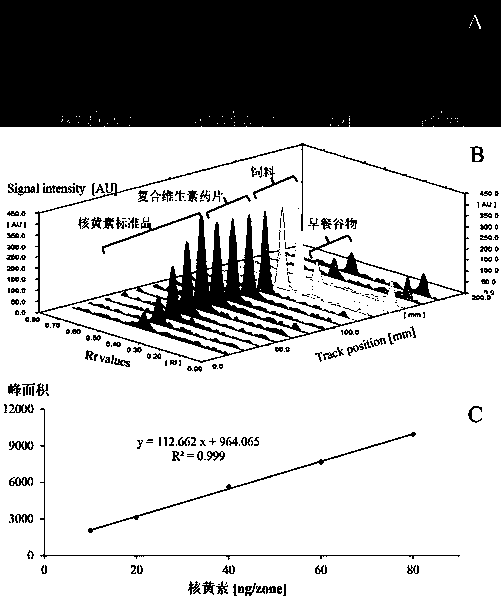

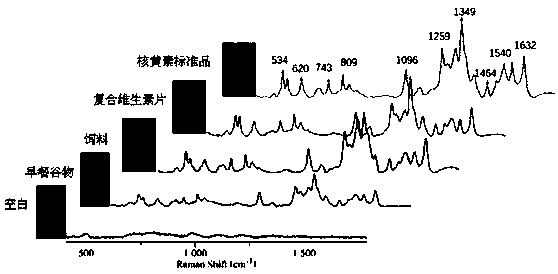

[0024] (3) High-efficiency thin-layer chromatography separation: 2-8μL riboflavin standard solution is accurately spotted with Linomat 5, and after sample spotting is completed, use a developing solution (methanol / ethyl acetate / triethylamine / water=2 / 8 / 1.5 / 1 (v / v)) to expand, expand 60 mm upwards, take out the silica gel plate ...

Embodiment 2

[0029] Riboflavin in multivitamin tablets, breakfast cereals and feed was tested separately.

[0030] (1) Pretreatment of multivitamin tablets: Grind the tablet into powder, weigh 0.5 g and dissolve it in 10 mL of 1% ammonia water, take it out after ultrasonication for 20 min, centrifuge at 3500 r / min for 10 min, pass through a 0.45 μm water film to obtain the tablet Samples were refrigerated at 4°C.

[0031] Pretreatment of breakfast cereals: Grind the cereals separately, weigh 2.5 g, add 10 mL of 0.1 mol / L hydrochloric acid, and heat in an autoclave at 121 °C for 15 min. Take it out and cool it to room temperature, adjust the pH to 6.8-7.2 with 1 mol / L sodium hydroxide, add 1 mL of peak amylase and place it at 37°C for 4 h. After finishing, dilute to 50 mL with methanol. After centrifugation, the supernatant was passed through a membrane to obtain a grain sample, which was refrigerated at 4°C.

[0032] Feed pretreatment is the same as breakfast cereals.

[0033] (2) Thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com