Method for preparing equiaxed alpha-phase silicon nitride powder

A technology of phase silicon nitride powder and phase silicon nitride, which is applied in the field of inorganic non-metallic materials, can solve the problems of difficult densification of ceramic products, reduce the mechanical properties and thermal properties of silicon nitride ceramics, etc. Shape and size, the effect of easy control of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Pour 500 volumes of diluent xylene and 200 volumes of liquid ammonia into the reaction kettle at -60°C; add 25 volumes of silicon tetrachloride diluted with 125 volumes of toluene into the reaction kettle through the feeding tube, four Silicon chloride and liquid ammonia react at the liquid phase interface at -50°C for 1 hour to obtain a fluffy white solid substance; after washing the white solid substance with liquid ammonia, vacuum it at 120°C (vacuum degree is 5×10 -2 Pa) drying for 8 hours to obtain silicon imine;

[0064] Pour the dried white solid silicon imide into a graphite crucible, place it in a tube furnace, and thermally decompose it under the conditions of 900°C, heat preservation for 2h, and nitrogen flow rate of 40mL / min to obtain white fluffy amorphous silicon nitride powder ;

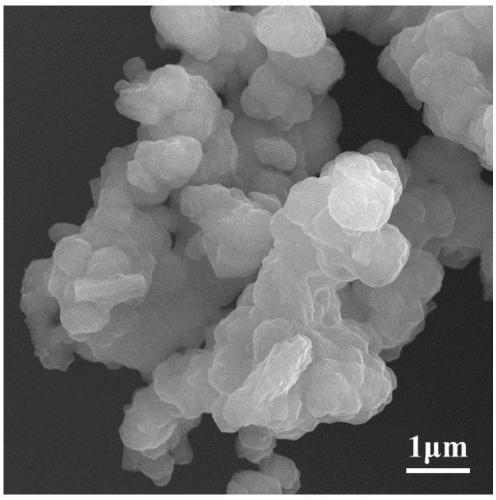

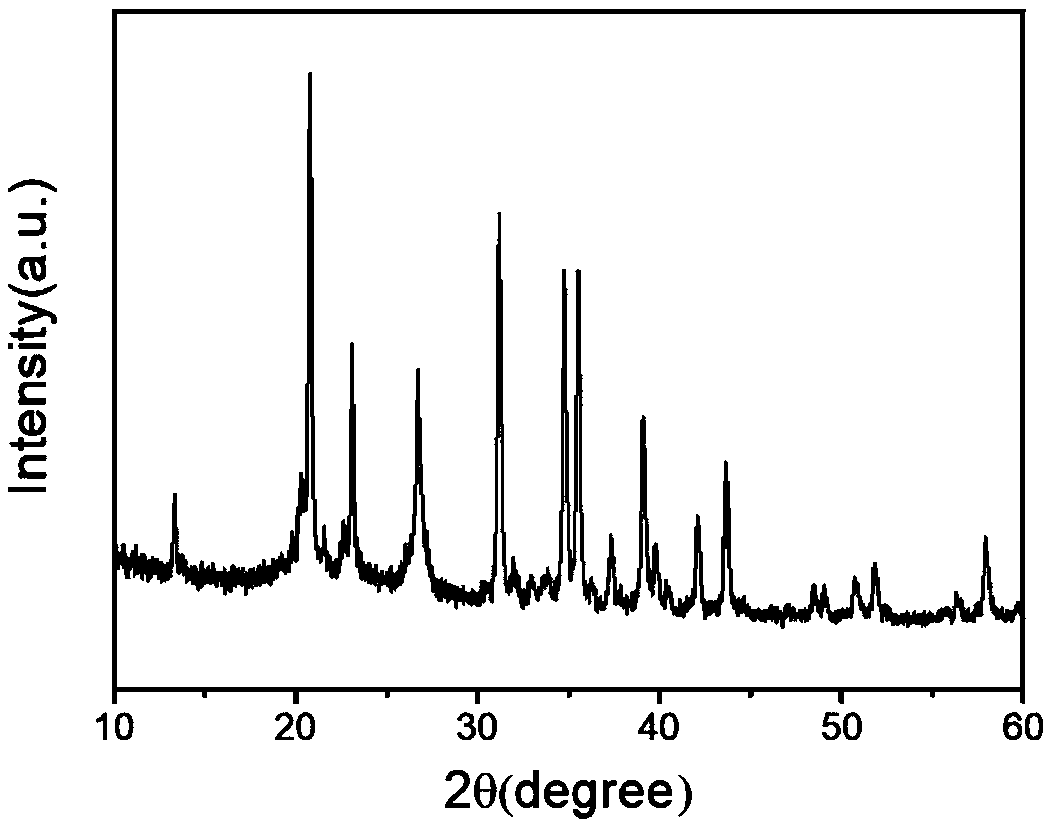

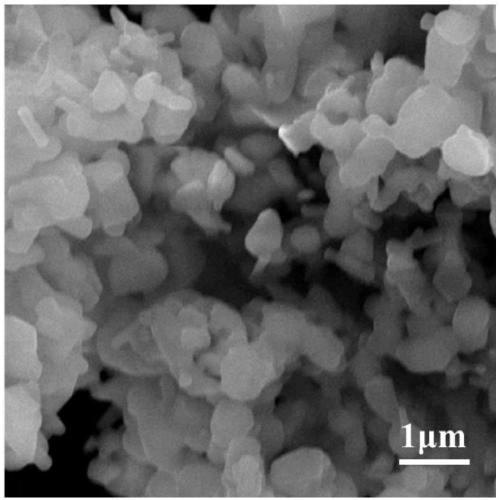

[0065] 15wt% α-Si 3 N 4 Mix with 75wt% amorphous silicon nitride powder, ball mill for 20min at 20°C, the ball milling speed is 100rpm, the particle size of the amorphous sil...

Embodiment 2

[0068] Pour 500 volumes of toluene and 200 volumes of liquid ammonia into the reaction kettle at -20°C; add 25 volumes of silicon tetrachloride diluted with 125 volumes of toluene into the reaction kettle through the feeding tube, silicon tetrachloride React with liquid ammonia at -50°C for 0.5h at the liquid phase interface to obtain a fluffy white solid substance; after washing the white solid substance with liquid ammonia, vacuum it at 120°C (vacuum degree is 5×10 -2 Pa) drying for 8 hours to obtain silicon imine;

[0069] Pour the dried white solid into a graphite crucible, place it in a tube furnace, and thermally decompose it under the conditions of 1000°C, heat preservation for 1h, and ammonia flow rate of 60mL / min to obtain white fluffy amorphous silicon nitride powder;

[0070] 15wt% α-Si 3 N 4 Mix with 75wt% amorphous silicon nitride powder, ball mill for 20min at 20°C, the ball milling speed is 100rpm, the particle size of the amorphous silicon nitride powder afte...

Embodiment 3

[0073] Pour 500 volumes of a mixed solution of toluene and cyclohexane with a volume ratio of 300:200 and 200 volumes of liquid ammonia into a reaction kettle at -50°C; 25 volumes of silicon tetrachloride diluted with 125 volumes of toluene, Add it into the reaction kettle through the feeding tube, and react silicon tetrachloride and liquid ammonia at the liquid phase interface at -45°C for 1 hour to obtain a fluffy white solid substance; after washing the white solid substance with liquid ammonia, vacuum it at 120°C (vacuum degree is 5×10 -2 Pa) drying for 8 hours to obtain silicon imine;

[0074] Pour the dried white solid into a boron nitride crucible, place it in a tube furnace, and thermally decompose it under the conditions of 1000°C, heat preservation for 3h, and nitrogen flow rate of 40mL / min to obtain white fluffy amorphous silicon nitride powder;

[0075] 10wt% KCl and 90wt% amorphous silicon nitride powder were ball-milled at 20°C for 20 minutes, the milling speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com