Preparation method of high-purity tricresyl phosphate

A high-purity technology of tricresyl phosphate, which is applied in the field of preparation of high-purity tricresyl phosphate, can solve problems such as slow hydrolysis of tricresyl phosphate, difficult environmental protection process improvement, and impact on storage stability, etc., to achieve economical and fast High purity, low loss, and loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In a 5000mL three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer, a condenser, and a hydrogen chloride tail gas absorption device, 2703 g of m-p-cresol was added (o-cresol was not detected, and the total content of m-p-cresol was 99.53%. The molar ratio of phenol to p-cresol is 6.5:3.5), phosphorus oxychloride 1128g, catalyst anhydrous aluminum chloride 3.8g, start stirring and slowly heat up to 150°C, and react at this temperature for 12 hours. After the reaction product was distilled under reduced pressure at 150° C. and 5 kPa vacuum for 10 h, its acid value was detected. When detecting that its acid value is 2.64mgKOH / g, stop vacuum distillation.

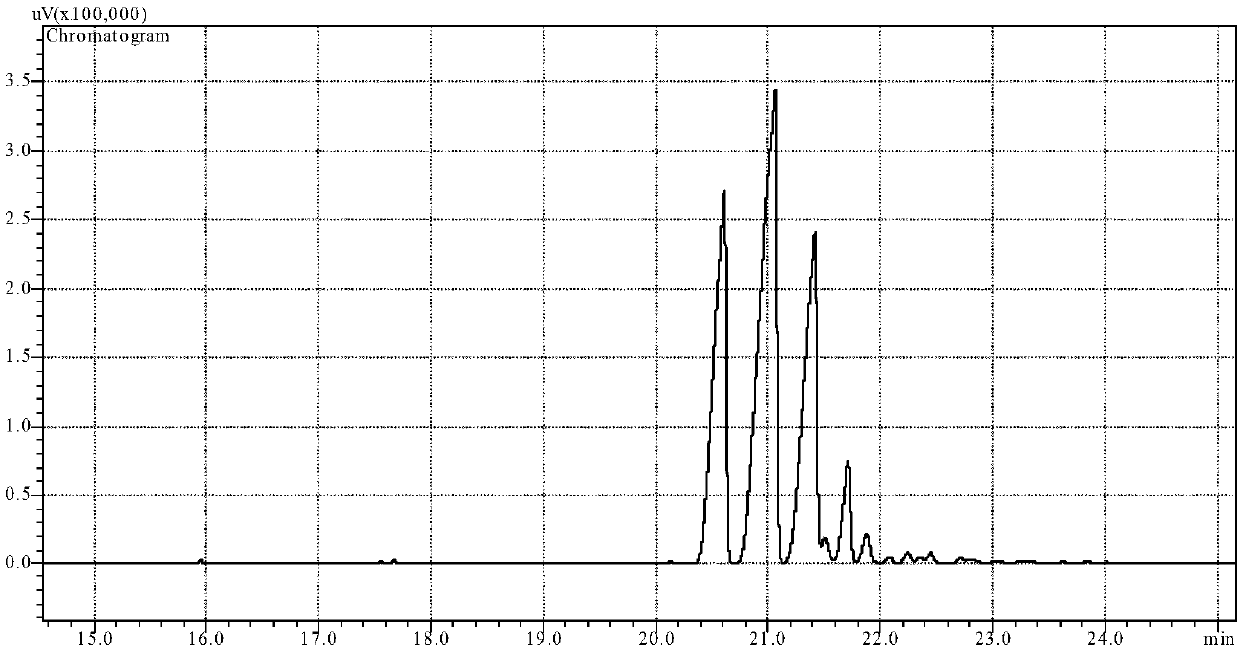

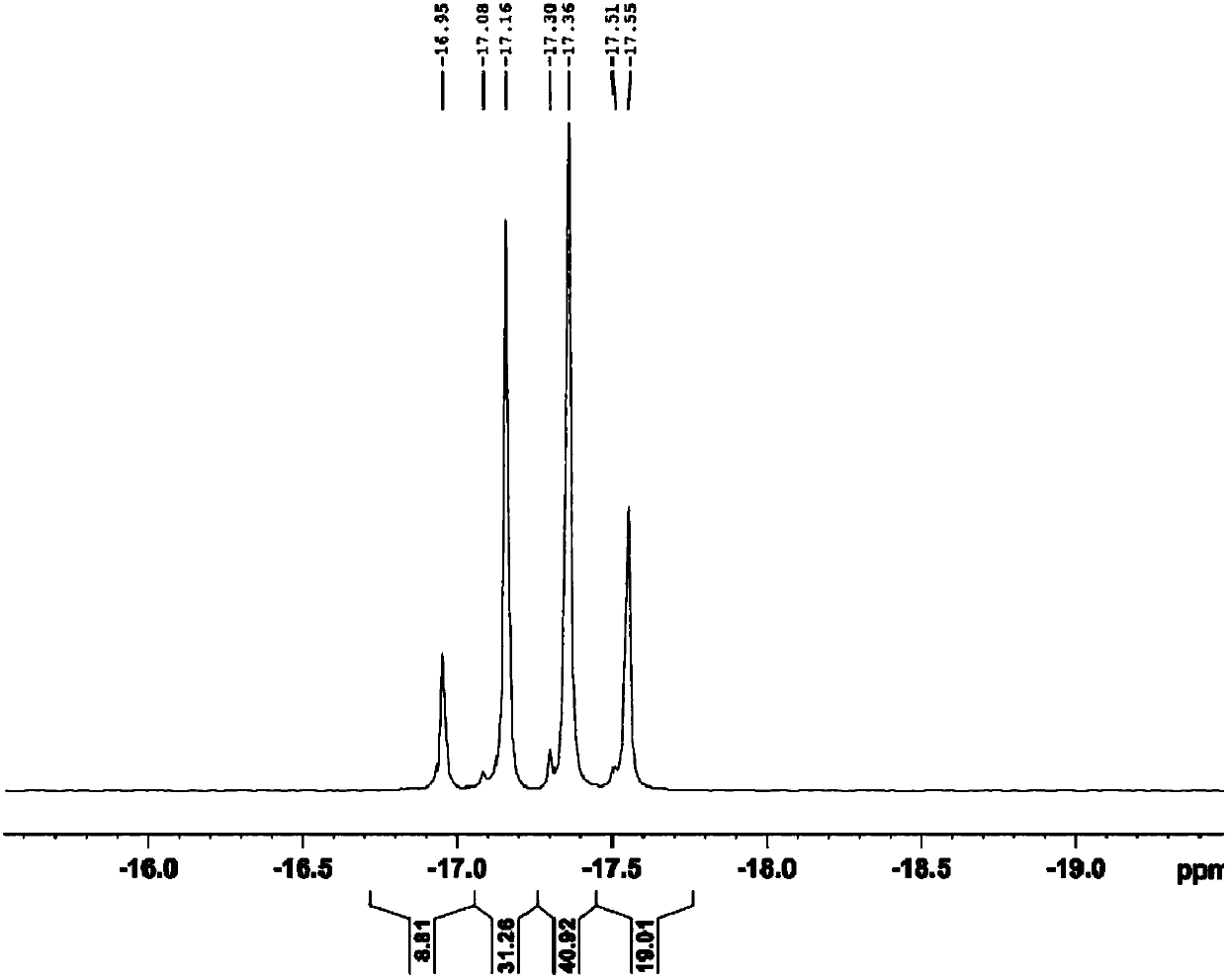

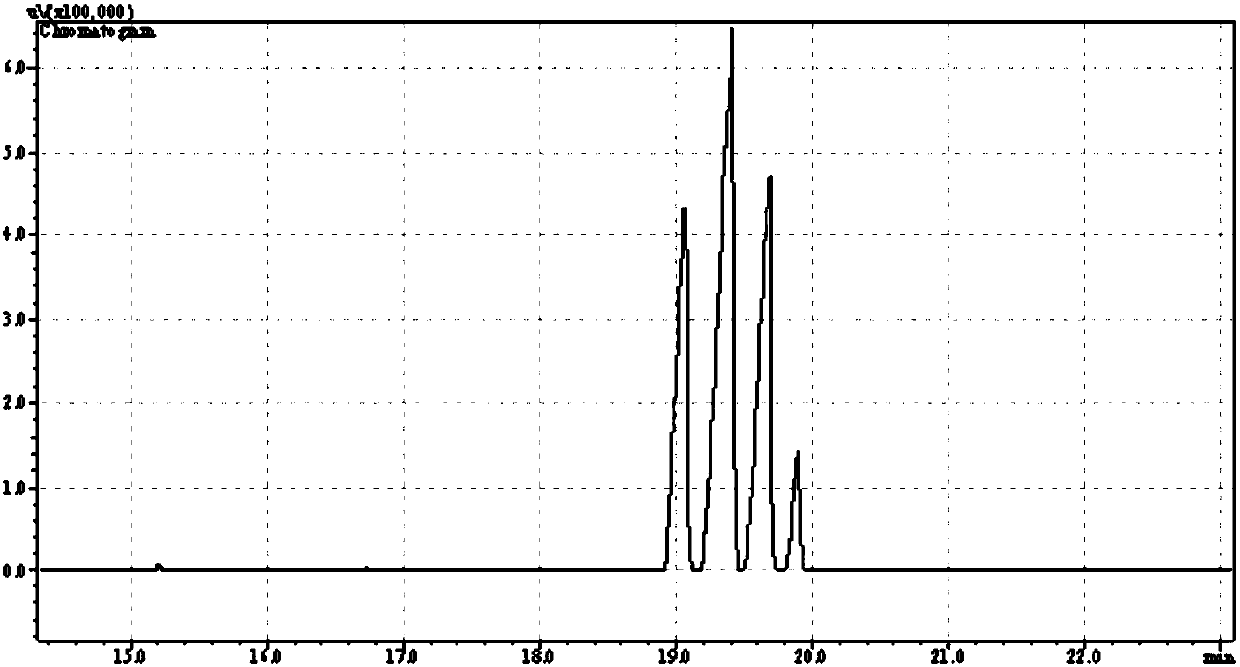

[0045] The above-mentioned crude product is introduced into molecular distillation equipment for the first stage of light phase impurity removal treatment. Set the evaporation temperature at 155°C and the vacuum degree at 15Pa, adjust the other molecular distillation parameters, and keep the...

Embodiment 2

[0048] In a 5000mL three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer, a condenser, and a hydrogen chloride tail gas absorption device, add 2703 g of m-p-cresol (o-cresol has not been detected, and the total content of m-p-cresol is 99.76%, and m-p-cresol The molar ratio of phenol to p-cresol is 7:3), phosphorus oxychloride 1100g, catalyst anhydrous aluminum chloride 3.8g, start stirring and slowly heat up to 150°C, and react at this temperature for 12 hours. After the reaction product was distilled under reduced pressure at 140° C. and 5 kPa vacuum for 10 h, its acid value was detected. When the acid value was detected to be 2.71 mgKOH / g, the vacuum distillation was stopped.

[0049] The above-mentioned crude product is introduced into molecular distillation equipment for the first stage of light phase impurity removal treatment. Set the evaporation temperature at 155°C and the vacuum degree at 10Pa, adjust the other molecular distillation pa...

Embodiment 3

[0052] In a 5000mL three-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer, a condenser, and a hydrogen chloride tail gas absorption device, add m-p-cresol 2703g (o-cresol is not detected, and the total content of m-p-cresol is 99.46%, m-p-cresol The molar ratio of phenol to p-cresol is 6.3:3.7), phosphorus oxychloride 1100g, catalyst anhydrous aluminum chloride 3.8g, start stirring and slowly heat up to 150°C, and react at this temperature for 12 hours. After the reaction product was distilled under reduced pressure at 150° C. and 4 kPa vacuum for 10 h, its acid value was detected. When the acid value was detected to be 1.34 mgKOH / g, the vacuum distillation was stopped.

[0053] The above-mentioned crude product is introduced into molecular distillation equipment for the first stage of light phase impurity removal treatment. Set the evaporation temperature at 156°C and the vacuum degree at 2Pa, adjust the other molecular distillation parameters, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com