A kind of flux-free vacuum casting high-purity magnesium alloy and its preparation method

A vacuum casting and magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems of less shrinkage porosity and ingot defects, and achieve the effects of less shrinkage porosity, less ingot defects, and avoiding oxidation inclusions and flux slag inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

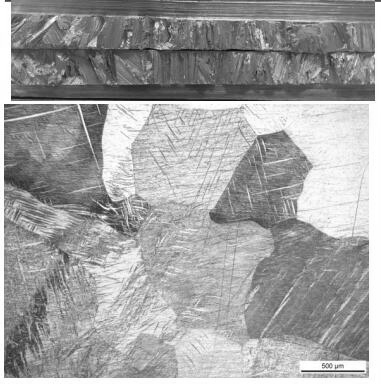

Image

Examples

Embodiment 1

[0034] A preparation method of a high-purity magnesium alloy for flux-free vacuum casting, the specific implementation steps are as follows:

[0035] The selected alloy composition (mass percentage) is: 13% Gd, 3.8% Y, 1.8% Zn, 0.5% Ca, 0.6% Zr, of which the total amount of impurity elements Fe, Ni, Si, etc. is less than 0.1%, and the balance is Mg.

[0036] Its preparation process is:

[0037] (1) Preheating of raw materials: batching is carried out according to the ratio of the above elements. The raw materials used in batching are semi-continuous pure magnesium, pure zinc, pure calcium, Mg-30Gd and Mg-30Y (wt.%) master alloy and Mg-30Zr ( wt.%) master alloy, first remove the surface oxide skin of pure magnesium, pure zinc, pure calcium, magnesium rare earth master alloy and magnesium-zirconium master alloy, and then put it into a desktop furnace for preheating, the preheating temperature is 150 ℃;

[0038] (2) Vacuuming: The melting and casting equipment adopts a power fre...

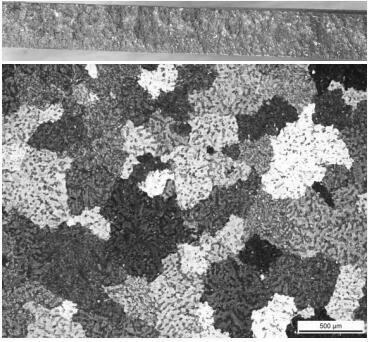

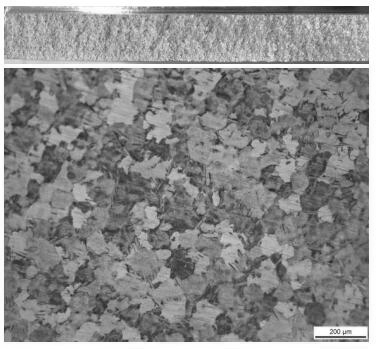

Embodiment 2

[0048] A preparation method of a high-purity magnesium alloy for flux-free vacuum casting, the specific implementation steps are as follows:

[0049] The selected alloy composition (mass percentage) is: 11% Gd, 1%Y, 1%Ce, 1.2% Zn, 0.3% Ca, 0.5%Zr, of which the total amount of impurity elements Fe, Ni, Si, etc. is less than 0.1%, and the balance for Mg.

[0050] Its preparation process is:

[0051] (1) Preheating of raw materials: batching is carried out according to the ratio of the above elements. The raw materials used in batching are semi-continuous pure magnesium, pure zinc, pure calcium, Mg-30Gd, Mg-30Y and Mg-30Ce (wt.%) master alloy and Mg-30Zr (wt.%) master alloy, first remove the surface oxide skin of pure magnesium, pure zinc, pure calcium, magnesium rare earth master alloy and magnesium-zirconium master alloy, and then put it into a table furnace for preheating, the preheating temperature is 120°C;

[0052] (2) Vacuumize. The melting and casting equipment adopts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com