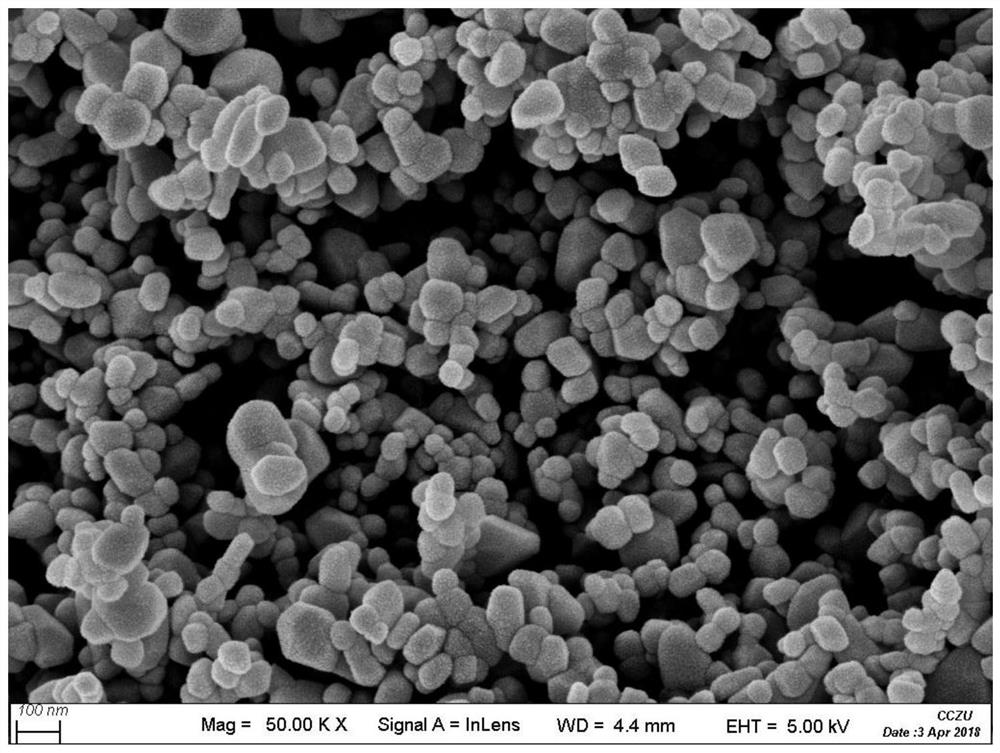

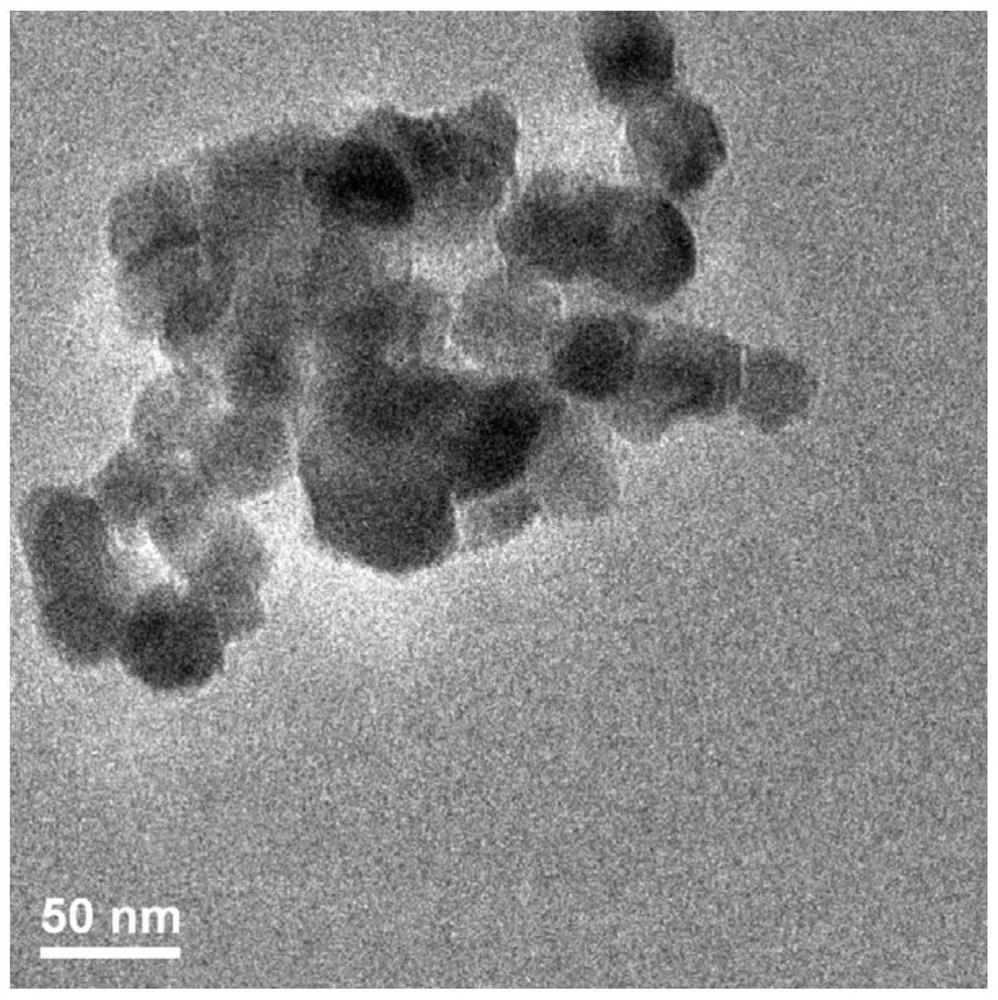

Preparation method of raw material low-Fe-ion and low-Ca-ion nano oxide for MLCC

A nano-oxide and ion technology, applied in the preparation/processing of rare earth metal compounds, nanotechnology for materials and surface science, rare earth metal oxides/hydroxides, etc., can solve the problem of high impurities, difficult to dry, Cost increase and other issues, to achieve the effect of reducing impurity content and high purity of precipitant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) preparation concentration is the yttrium chloride feed liquid of 0.4mol / l, and the acidity of control yttrium chloride feed liquid is less than 0.3mol / l;

[0025] (2) According to the mol ratio of yttrium chloride and precipitating agent, add sodium carbonate at 1:1.6, the concentration of sodium carbonate solution is 0.5mol / l, then add 2% dispersant PEG2000, add dropwise precipitation; sodium carbonate solution It needs to be filtered through membrane filtration equipment before use. Time required to filter sodium carbonate solution: 1.5h.

[0026] (3) After the dropwise addition, control the pH of the precipitate to be 6.5-7, stir for 1h, and age for 2h;

[0027] (4) Put the slurry into the plate and frame filter press first, press the mother liquor as dry as possible, then put the filter cake into the suction filter barrel, stir and wash with water at a temperature of 50°C, and wash until the waste water is titrated with silver nitrate without precipitation . ...

Embodiment 2

[0030] 1) preparation concentration is the holmium cerium chloride feed liquid of 0.3mol / l, and the control holmium chloride feed liquid acidity is less than 0.3mol / l;

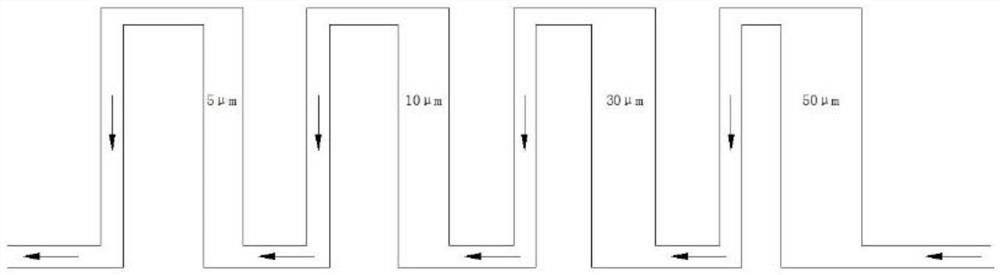

[0031] (2) According to the molar ratio of holmium chloride and precipitant: add sodium bicarbonate at 1:1.5, the concentration of sodium bicarbonate solution is 0.5mol / l, then add 2.5% dispersant PEG2000, add dropwise precipitation; The sodium hydrogen solution needs to be filtered through an improved membrane filtration device before use, and the time required to filter the sodium carbonate solution: 1h.

[0032] (3) After the dropwise addition, control the pH of the precipitate to be 6.5-7, stir for 1h, and age for 2h;

[0033] (4) Put the slurry into the plate and frame filter press first, press the mother liquor as dry as possible, then put the filter cake into the suction filter barrel, stir and wash with water at a temperature of 55°C, and wash until the waste water is titrated with silver nitrate witho...

Embodiment 3

[0036] (1) preparation concentration is the erbium chloride feed liquid of 0.6mol / l, and the control erbium chloride feed liquid acidity is less than 0.3mol / l;

[0037] (2) According to the mol ratio of erbium chloride and precipitating agent, add sodium carbonate at 1:1.6, the concentration of sodium carbonate solution is 0.6mol / l, then add 3% dispersant PEG2000, add dropwise precipitation; sodium carbonate solution It needs to be filtered through improved membrane filtration equipment before use. Time required to filter sodium carbonate solution: 1.5h.

[0038] (3) After the dropwise addition, control the pH of the precipitate to be 6.5-7, stir for 1h, and age for 2h;

[0039] (4) Put the slurry into the plate and frame filter press first, press the mother liquor as dry as possible, then put the filter cake into the suction filter barrel, stir and wash with water at a temperature of 60°C, and wash until the waste water is titrated with silver nitrate without precipitation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com