Preparation method of a sintered NdFeB magnet

A NdFeB magnet technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems that it is impossible to prepare large magnets, it is difficult to ensure the magnetic properties of NdFeB magnets, and it is difficult to grind. Achieve excellent comprehensive magnetic properties, suppress magnetization reversal process, and high intrinsic coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

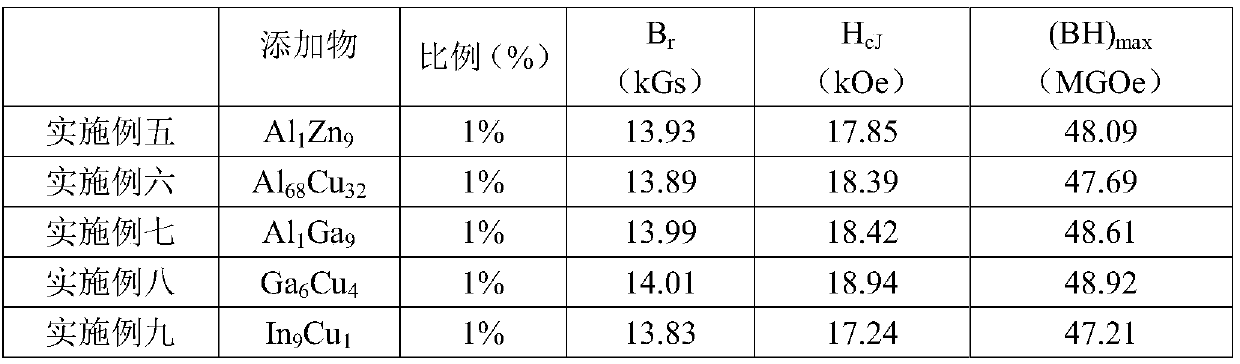

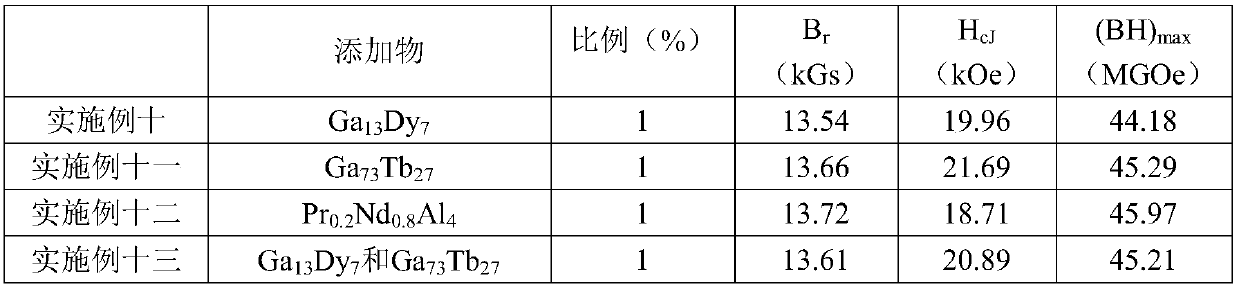

Examples

Embodiment 1

[0018] Embodiment one: a kind of preparation method of sintered NdFeB magnet, comprises the following steps:

[0019] (1) According to the composition (PrNd) 30.5 Fe bal Al 0.2 Zr 0.1 Cu 0.1 B 1 (percentage by weight) is proportioned, using Pr-Nd, Fe, Co, Al, Zr, Cu and B-Fe alloys with a purity greater than 99% (percentage by weight), and intermediate frequency melting the above materials in an argon atmosphere to obtain a solution , and then the solution is cast on a water-cooled copper roller with a linear speed of 1.5m / s to prepare a neodymium-iron-boron alloy material, which is a quick-setting sheet with an average thickness of 0.28mm;

[0020] (2) Mix quick-setting flakes with low-melting-point metal materials and carry out hydrogen crushing. During the hydrogen crushing process, rotate and stir. The dehydrogenation temperature is 500-700 ° C, and the dehydrogenation time is 4 hours. The mixed alloy is coarsely crushed into a particle size of 0.5 Coarse powder part...

Embodiment 2

[0024] Embodiment 2: This embodiment is basically the same as Embodiment 1, except that in this embodiment, the low melting point metal material is 2 wt.% Ga.

Embodiment 3

[0025] Embodiment 3: This embodiment is basically the same as Embodiment 1, except that in this embodiment, the low melting point metal material is 0.5 wt.% In.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com