Preparation method of neodymium-iron-boron magnet with adjustable grain boundary

A technology of NdFeB and grain boundaries, which is applied in the direction of magnetic objects, inductors/transformers/magnets manufacturing, magnetic materials, etc., can solve the problem that the magnets do not provide effective control of grain boundaries, etc., and achieve reduced production costs and simple experimental conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Take the NdFeB magnet intermediate, the intermediate satisfies the total amount of Pr, Nd, and Ce at 34.67wt%, the ratio of Pr / Nd is 0.16, the Tb content is 1.13wt%, and the total amount of Al, Cu, Ga, and Mg is 2.22wt%, Cu / Al is 1.26, Cu / Ga is 6, the total of Co, Ti, Zn, Sn is 1.42wt%, B content is 1.04wt%, and the high temperature diffusion of NdFeB magnet is 900℃×10 h, the heating rate is 5 °C / min, the aging temperature is 480 °C × 8 h, Ar gas positive pressure circulation cooling, and the cooling pressure is 1500 mbar.

[0051] 2) NdFeB permanent magnet performance: a magnet with an intrinsic coercivity Hcj of 29 Koe, a remanence Br of 12.5 kGs, and a grain boundary width of 800 nm.

Embodiment 2

[0053] 1) Take the NdFeB magnet intermediate, the intermediate meets the total amount of Pr, Nd, and Ce is 32.79 wt%, the ratio of Pr / Nd is 0.05, the Dy content is 0.98 wt%, and the total amount of Al, Cu, Ga, and Mg is 1.62 wt%, Cu / Al is 0.53, Cu / Ga is 2.5, the total of Co, Ti, Zn, Sn is 1.47 wt%, B content is 1.08 wt%, and the high temperature diffusion of NdFeB magnet is 940℃×8 h, the heating rate is 4°C / min, the aging temperature is 500°C×6 h, Ar gas positive pressure circulation cooling, and the cooling pressure is 1000 mbar.

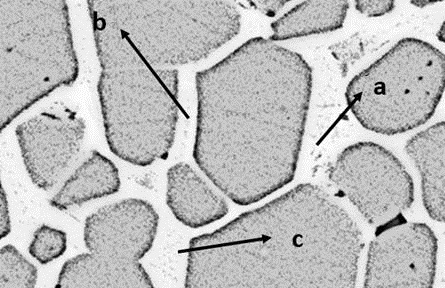

[0054] 2) NdFeB permanent magnet performance: the intrinsic coercive force Hcj is 27 Koe, the remanence Br is 13.2 kGs, and the grain boundary width is 300 nm. See the backscattered electron picture, such as image 3 .

Embodiment 3

[0056] 1) Take the NdFeB magnet intermediate, the intermediate satisfies the total amount of Pr, Nd, Ce is 37.75 wt%, the ratio of Pr / Nd is 0.53, the total amount of Al, Cu, Ga, Mg is 2.35 wt%, Cu / Al is 0.16, Cu / Ga is 0.75, Mg / Al is 1.11, the total amount of Co, Ti, Zn, and Sn is 1.5wt%, and the B content is 1.1wt%. The high temperature diffusion of NdFeB magnet is 850℃×20 h , the heating rate is 6°C / min, the aging temperature is 460°C×10 h, Ar gas positive pressure circulation cooling, and the cooling pressure is 3000 mbar.

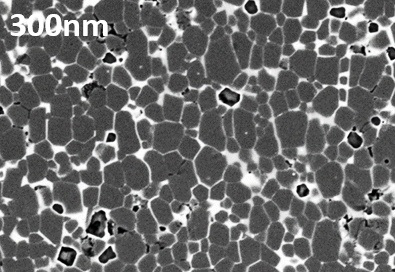

[0057] 2) NdFeB permanent magnet performance: the intrinsic coercive force Hcj is 24Koe, the remanence Br is 12.8 kGs, and the grain boundary width is 600 nm. See the backscattered electron picture, such as Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com