Design and preparation method of a construction waste powder-based ecological ultra-high performance concrete

A construction waste and ultra-high performance technology, which is applied in the design and preparation of construction waste powder-based ecological ultra-high performance concrete, can solve problems such as fluidity, poor pumping performance, impact on engineering construction, and complex composition. achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A design and preparation method of construction waste powder-based ecological ultra-high performance concrete, comprising the following steps:

[0043] Select 52.5P.O. cement (Cement), silica fume (Silica Fume) and fly ash (Fly Ash) (where silica fume and fly ash are used as mineral admixtures), construction waste powder (construction and demolition wastes), River sand, active activator, water, and polycarboxylate superplasticizer are used as raw materials.

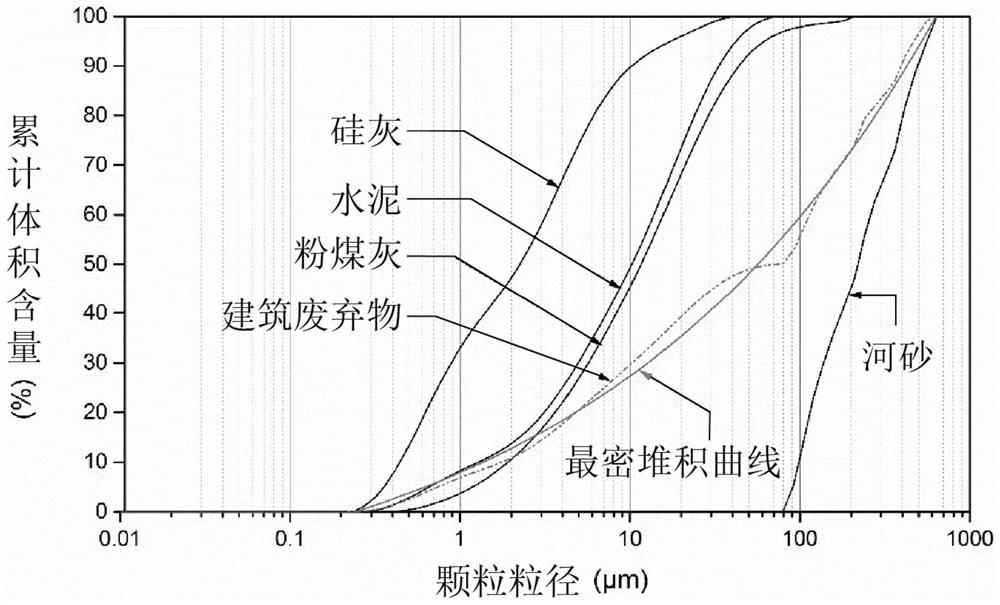

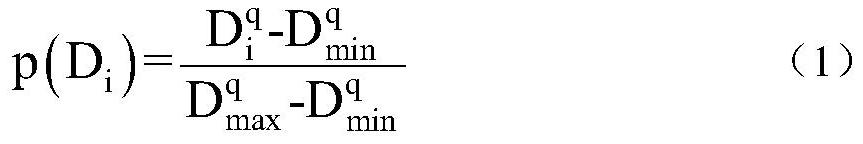

[0044] Step (1), determine the composition and bulk density of the construction waste powder, and test the particle size distribution of the powder, such as figure 1 As shown, determine the particle size and particle size distribution curve corresponding to the volume distribution of 10%, 50%, and 90%;

[0045] The specific implementation process of step (1) is as follows:

[0046] 1.1. Collect construction waste powder;

[0047] 1.2. Determine the composition of the construction waste powder, the specific deter...

Embodiment 2

[0092] The purpose of this embodiment is to also provide a method for determining the composition of raw materials used to prepare construction waste powder-based ecological ultra-high performance concrete, including the following steps:

[0093] Step (1), determine the composition and bulk density of the construction waste powder, and test the particle size distribution of the powder, such as figure 1 As shown, determine the particle size and particle size distribution curve corresponding to the volume distribution of 10%, 50%, and 90%;

[0094] The specific implementation process of step (1) is as follows:

[0095] 1.1. Collect construction waste powder;

[0096] 1.2. Determine the composition of the construction waste powder, the specific determination method is as follows: For example, the composition of the collected construction waste powder can be determined by X-ray energy spectrum or X-ray diffraction or X-ray fluorescence spectrum. In this embodiment, it is determi...

Embodiment 3

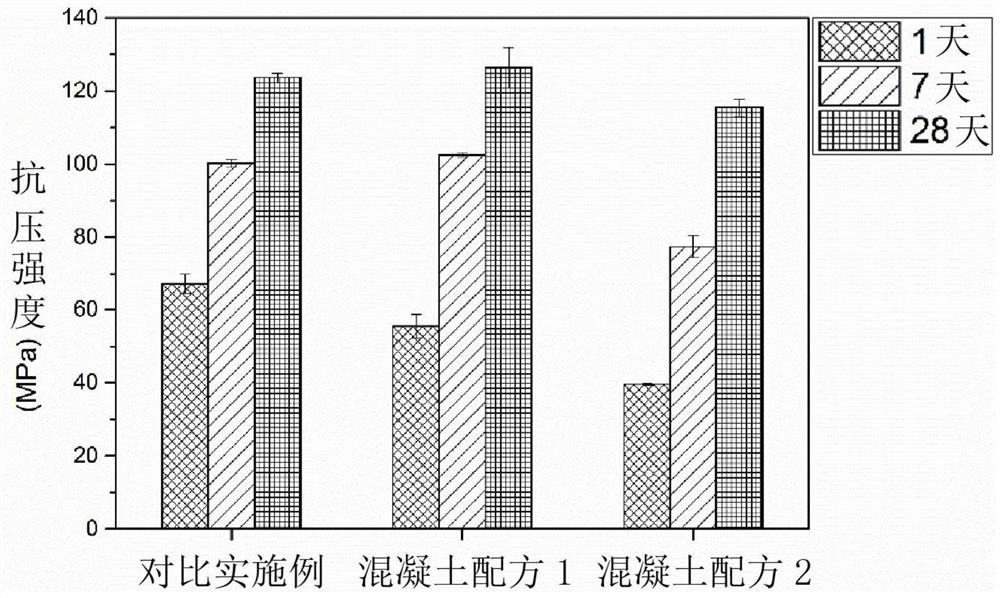

[0143] The purpose of this embodiment is to also provide a kind of construction waste powder-based ecological ultra-high performance concrete. In parts by weight, the composition includes 401-536 parts of cement, 200-202 parts of fly ash, and 186-189 parts of silica fume. 213-432 parts of construction waste powder, 818-904 parts of river sand, 14-31 parts of active activator, 30-31 parts of polycarboxylate superplasticizer and 210-212 parts of water.

[0144] The construction waste powder-based ecological ultra-high-performance concrete disclosed in this embodiment uses construction waste powder to replace cement, which can reduce the amount of cement, and can prepare ultra-high-performance concrete with excellent performance (compressive strength and rheological properties). Realize energy saving and emission reduction and sustainable development of building materials.

[0145] Among them, the construction waste powder can be selected as construction waste with a particle siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com