Color-development-adjustable vanadium dioxide based thermochromic composite material and application thereof

A thermochromic material, a vanadium dioxide-based technology, applied in the field of composite films, can solve the problems of affecting the thermochromic properties of composite materials, adverse effects of publicity and promotion, reducing the total insolation adjustment rate, etc., so as to improve the anti-ultraviolet radiation. Stability and solar regulation rate, improve the stability of anti-ultraviolet radiation, improve the effect of solar energy regulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Weigh 0.1g of vanadium dioxide particles (30-60nm in particle size) and ultrasonically disperse them in 2g of ethanol to form a 5wt% dispersion, then add 4g of silicone resin to it, and form a uniform slurry by magnetic stirring. Apply it on the substrate (glass, etc.), leave it at room temperature for 2 hours to cure (it can also be heated in an oven to accelerate its curing), and obtain a vanadium dioxide-based thermochromic film, which is yellow and has a thickness of 80 μm.

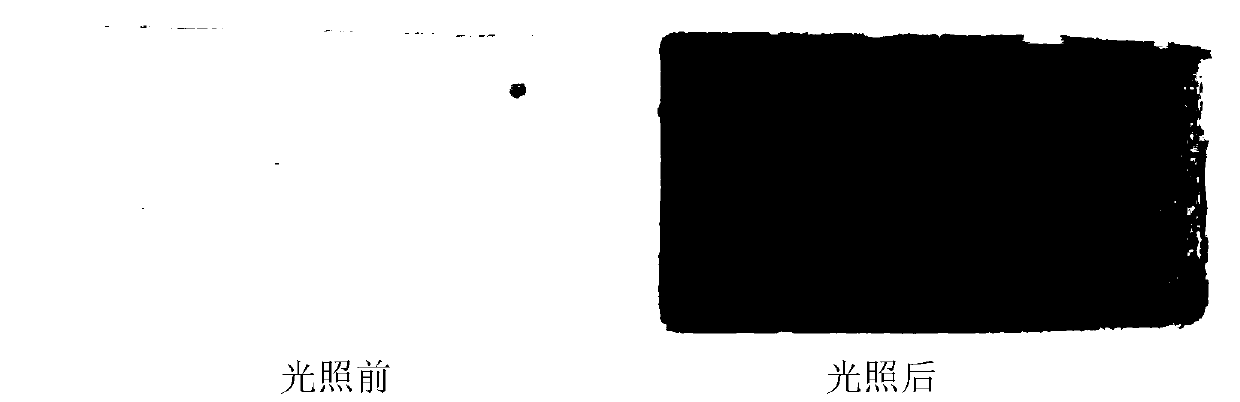

[0057] The photosensitive powder that absorbs ultraviolet light and turns blue uses toluene as a solvent to form a 3wt% dispersion by ball milling, takes 2g of the dispersion and adds 2.5g of polycrystalline resin and 1g of silicone resin to it, and magnetically stirs to form a uniform slurry. And scrape-coat it on the pre-prepared vanadium dioxide-based thermochromic film, and after it is cured, the color of the film (with a total thickness of 200 μm) will change from yellow to blue under sunli...

Embodiment 2

[0059] Add vanadium dioxide particles according to the mass ratio: photosensitive powder=2:1 and add in the ball mill, use toluene as solvent and mix with appropriate dispersant, obtain the mixed dispersion liquid containing vanadium dioxide-based thermochromic composite material, its concentration is respectively 5wt% and 2.5wt%, then take 2g of the dispersion and add 4g of silicone resin to it, form a uniform slurry by magnetic stirring, apply it on the substrate by scraping, and wait for it to solidify to obtain a thickness of 120μm Vanadium dioxide-based thermochromic composite film.

Embodiment 3

[0061] Prepare a vanadium dioxide-based thermochromic film according to Example 1, with a thickness of 80 μm;

[0062] Use toluene as a solvent to form a 3wt% dispersion by ball milling the photosensitive powder that absorbs ultraviolet light and turns blue. Take 0.5, 1, 3, and 4 g of the dispersion, and add 2.5 g of polycrystalline resin and 1 g of silicone resin to it, magnetically Stir to form a uniform slurry, and scrape-coat it on the pre-prepared vanadium dioxide-based thermochromic film to obtain a film with adjustable depth of discoloration (the total thickness is 200 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com