A kind of manufacture method and manufacture equipment of water-based leduv light-cured coating

A technology of photocuring coatings and manufacturing methods, which is applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as toughness difference, environmental protection and luster stability, etc., to achieve improved flexibility, good toughness and fullness, and curing speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of manufacture method of water-based LEDUV photocurable paint, is characterized in that, comprises the following steps:

[0037] S1. Select water-based polyurethane acrylate emulsion, water-based polyurethane acrylate dispersion, N-vinylpyrrolidone monomer, compound light stabilizer EVERSORBAQ7, LED photoinitiator, 2,4,6-trimethylbenzoyl- Diphenylphosphine oxide, defoamer, wetting agent, leveling agent and deionized water are used as raw materials;

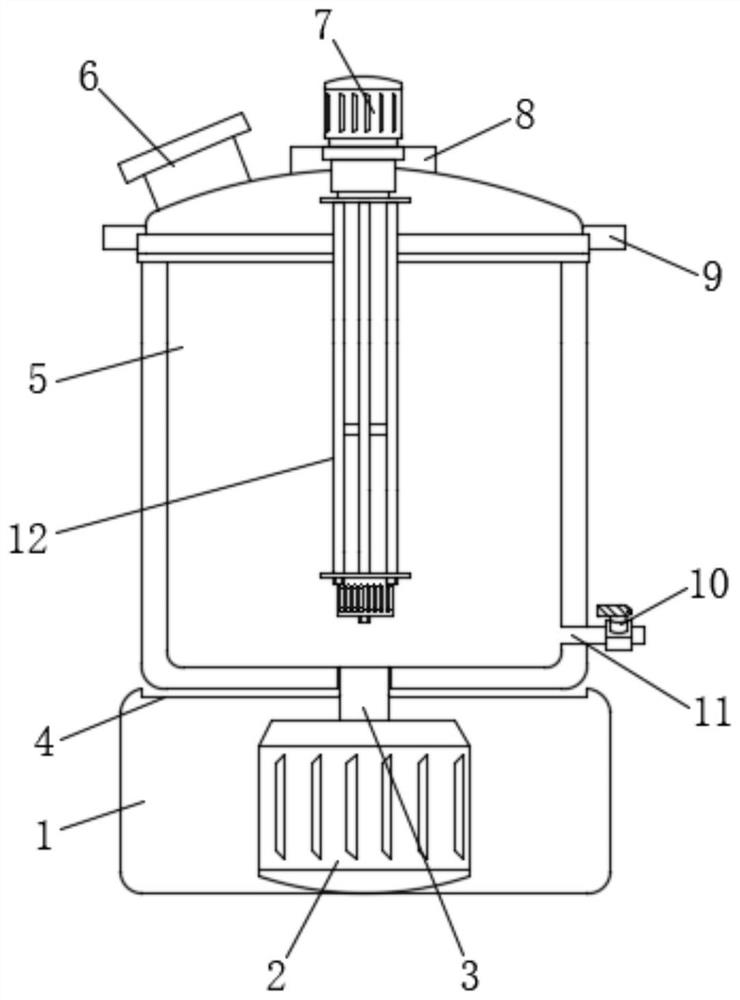

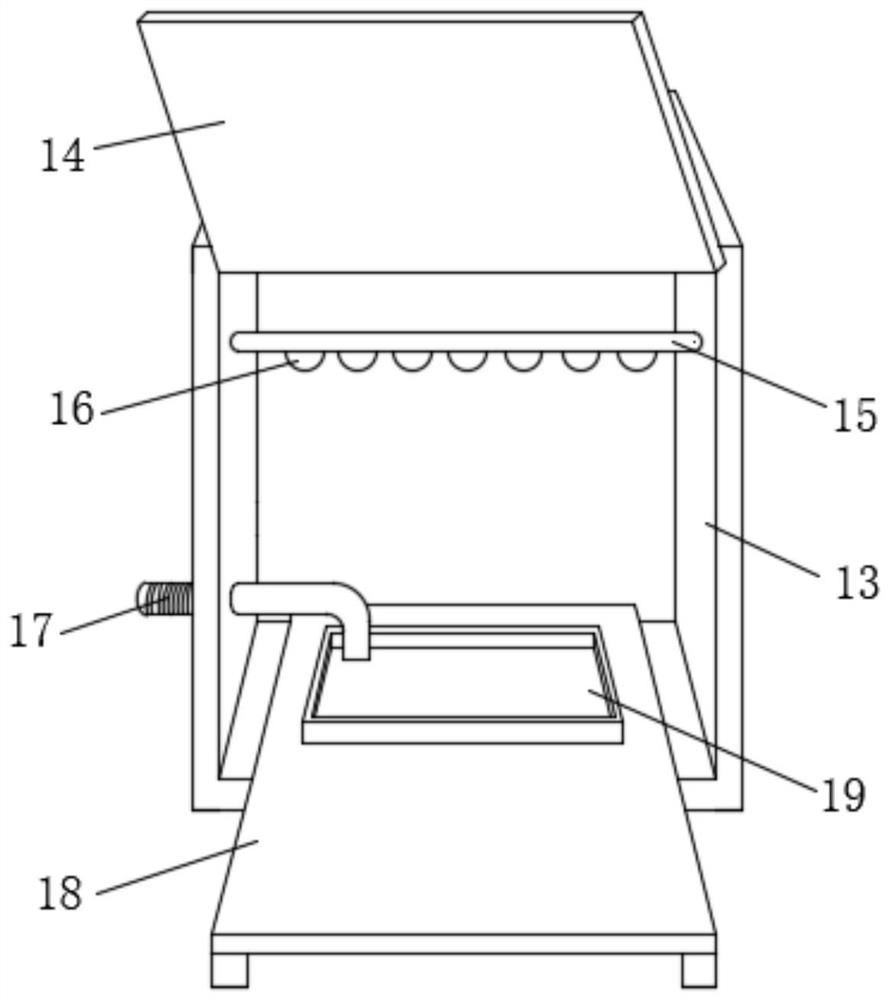

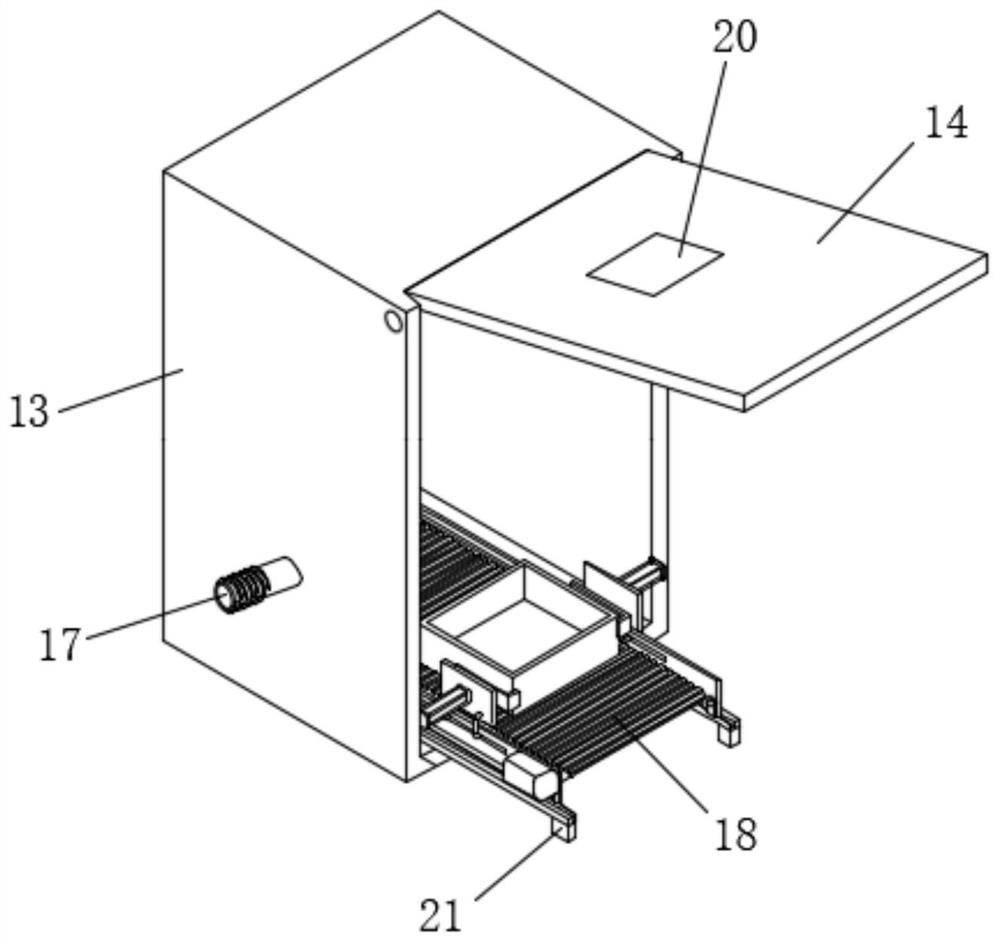

[0038] S2. Weigh an appropriate amount of water-based urethane acrylate emulsion and water-based urethane acrylate dispersion, mix them according to the ratio of 1:5-5:1 by mass, stir evenly, and prepare the composite UV resin raw material, and mix the UV resin raw material Add it into the stirring tank from the feed port;

[0039] S3. Weigh an appropriate amount of LED photoinitiator and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and mix them according to the mass ratio of 10:1-10:5 to obtain lig...

Embodiment 2

[0049] Example 2: Based on Example 1, the difference is that an appropriate amount of water-based urethane acrylate emulsion and water-based urethane acrylate dispersion is weighed, mixed according to a mass ratio of 1:1, stirred evenly, and added to the stirring In the tank, weigh an appropriate amount of defoamer and wetting agent, and add them to the stirring tank at the ratio of 1.0% and 0.5% of the mass of the composite UV resin raw material added, set the rotating speed of the rotating motor to 20rpm, and stir the stirring motor The speed is 600rpm, the stirring time is 20min, stir evenly, then N-vinylpyrrolidone monomer is added to the stirring tank in the proportion of 10% of the mass of the composite UV resin raw material, and the rotating speed of the rotating motor is set to 20rpm, and the stirring motor The stirring speed is 600rpm, the stirring time is 10min, stir evenly, weigh an appropriate amount of LED photoinitiator and 2,4,6-trimethylbenzoyl-diphenylphosphine...

Embodiment 3

[0051] Example 3: Based on Examples 1 and 2, the difference is that an appropriate amount of water-based urethane acrylate emulsion and water-based urethane acrylate dispersion is weighed, mixed according to a mass ratio of 1:2, stirred evenly, and added In the stirring tank, weigh an appropriate amount of defoamer and wetting agent, and add them to the stirring tank in the proportion of 2.0% and 1.0% of the quality of the composite UV resin raw material added, set the rotating speed of the rotating motor to 30rpm, stir The stirring speed of the motor is 800rpm, the stirring time is 30min, stir evenly, then N-vinylpyrrolidone monomer is added to the stirring tank in the proportion of 20% of the mass of the composite UV resin raw material, and the rotating speed of the rotating motor is set to 30rpm. The stirring speed of the stirring motor is 800rpm, and the stirring time is 15min. Stir evenly, take an appropriate amount of LED photoinitiator and 2,4,6-trimethylbenzoyl-diphenyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com