Tantalum steel composite plate and preparation method thereof

A composite plate and steel plate technology, applied in chemical instruments and methods, lamination, coating, etc., can solve problems such as unsatisfactory continuous production, high production site requirements, exhaust gas pollution, etc., and achieve a wide range of product sizes. The effect of good environment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for preparing a tantalum steel clad plate, specifically comprising the following steps:

[0027] 1) Select a carbon steel plate with a thickness of 100mm and a tantalum plate with a thickness of 10mm, and polish the surface to be bonded between the tantalum plate and the steel plate, so that the surface to be bonded has no oxide layer, impurities and voids, and presents a fresh metal surface;

[0028] 2) To prepare a release agent, take aluminum oxide powder and polyvinyl chloride powder with a mesh size greater than 200 and mix them with water in a ratio of (2-3): (1-2): 100 and stir evenly, and evenly spread it on the tantalum plate The non-joint surface, with a thickness of 0.3-0.8mm, should be dried statically or placed in an oven, and the temperature of the oven should not be higher than 180°C;

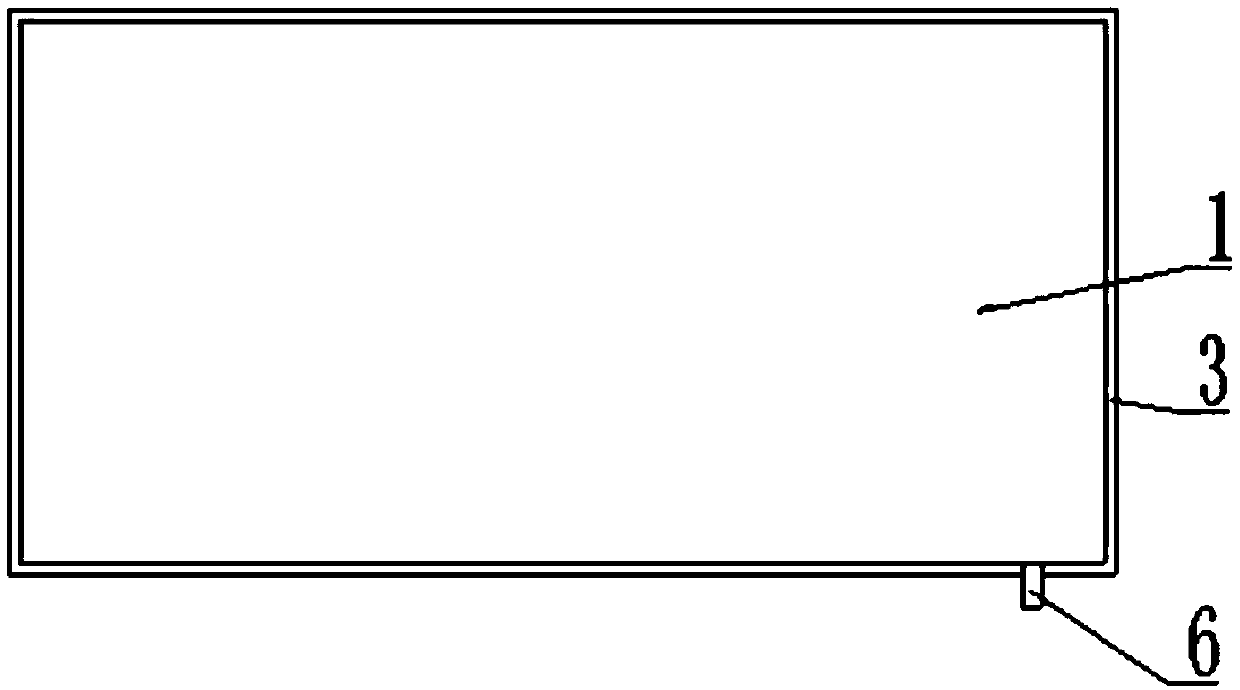

[0029] 3) if figure 1 As shown, place the side of the tantalum plate coated with the release agent 5 facing each other, and seal and weld the surrounding of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com