Heat conductive interface material for heat dissipation of electronic equipment

A technology of interface materials and electronic equipment, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of large diameter-thickness ratio of graphene materials, difficulty in dispersion of nanomaterials, easy agglomeration, etc., to reduce interface thermal resistance, The preparation process is simple and the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put 1g of intercalated graphene powder, 20g of spherical alumina filler with an average particle size of 3 μm, 100g of acrylic resin with a solid content of 45% and 1g of isocyanate into a ball mill jar, and stir for 10 minutes at a speed of 100 rpm. Add 100 g of zirconia balls to the ball mill jar. The mixture was ball milled at a speed of 400 rpm for 10 hours. After the ball milling is completed, the mixture is taken out to obtain a graphene-containing thermally conductive adhesive composite material.

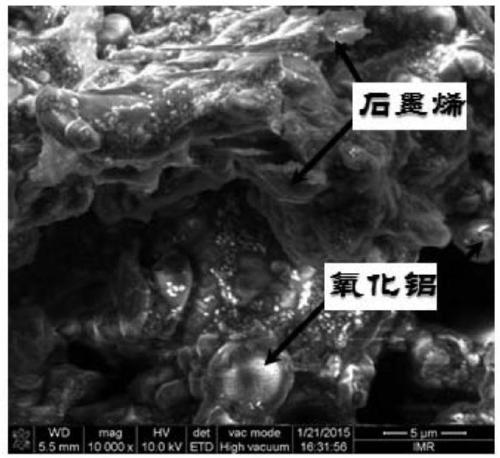

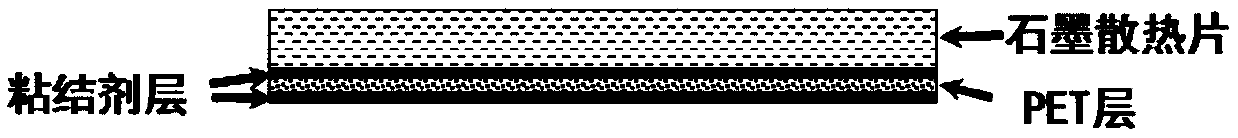

[0034] figure 1 Optical photographs of the prepared thermally conductive adhesive, figure 2 It can be seen from the scanning electron microscope photos that the graphene and alumina in the composite material are uniformly dispersed, and the graphene and alumina overlap and cooperate with each other to form a uniform and effective heat conduction network structure. Since the macroscopic and microscopic structures of the thermally conductive adhesives prepared in the...

Embodiment 2

[0037] Put 1g of intercalated graphene powder, 15g of aluminum nitride powder with an average particle size of 1 μm, 100g of acrylic resin with a solid content of 45% and 1g of isocyanate into a ball mill jar, and stir for 10 minutes at a speed of 100 rpm. Add 100 g of zirconia balls to the ball mill jar. The mixture was ball milled at a speed of 400 rpm for 10 hours. After the ball milling is completed, the mixture is taken out to obtain a graphene-containing thermally conductive adhesive composite material.

[0038] The thermal conductivity of the prepared graphene thermally conductive adhesive was measured to be 0.95W / mK. use Figure 5 The device shown is tested for cooling effect. The composite heat-dissipating film prepared by using this heat-conducting adhesive dissipates heat, and the center temperature of the ceramic heating sheet is 88.2°C.

Embodiment 3

[0040] Put 1g of electrolytic graphene powder, 15g of boron nitride powder with an average particle size of 1 μm, 100g of acrylic resin with a solid content of 45%, and 1g of isocyanate into a ball mill jar, and stir for 10 minutes at a speed of 100 rpm. Add 100 g of zirconia balls to the ball mill jar. The mixture was ball milled at a speed of 400 rpm for 10 hours. After the ball milling is completed, the mixture is taken out to obtain a graphene-containing thermally conductive adhesive composite material.

[0041] The thermal conductivity of the prepared graphene thermally conductive adhesive was measured to be 0.88W / mK. use Figure 5 The device shown is tested for cooling effect. The composite heat-dissipating film prepared by using this heat-conducting adhesive dissipates heat, and the center temperature of the ceramic heating sheet is 90.4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com