Pretreatment method of conductive polyester fibers, conductive polyester fibers and preparation method thereof

A polyester fiber pretreatment technology, applied in fiber treatment, fiber type, wear-resistant fiber, etc., can solve the problems of fiber damage, fiber performance degradation, environmental pollution, etc., and achieve the effect of overcoming fiber damage and improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

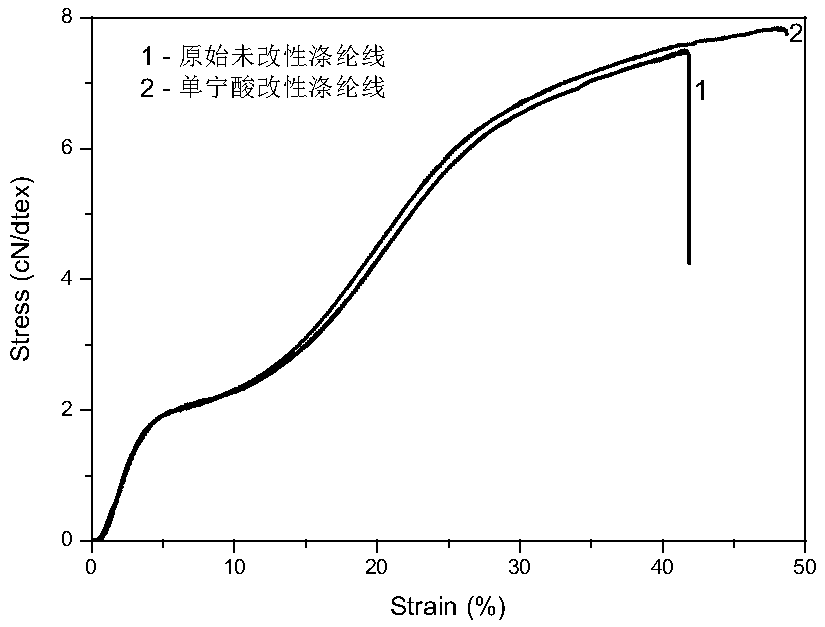

[0048] (1) Pre-soak the polyester thread with a 5 g / L tannic acid solution at room temperature for 1 hour, take out the polyester thread, wash it with deionized water three times, and dry it to obtain a tannic acid-modified polyester thread.

[0049] (2) Soak the tannic acid-modified polyester thread in 50 g / L copper sulfate pentahydrate solution for 1 hour, take it out, and obtain the modified polyester thread that absorbs copper ions.

[0050] (3) Treat the modified polyester thread adsorbed with copper ions with 0.01 mol / L sodium borohydride for 180 s to obtain a polyester thread uniformly attached to the metallic copper activation catalyst layer.

[0051] (4) Dissolve 2.0g copper sulfate pentahydrate, 0.4g nickel sulfate hexahydrate, and 10.0g potassium sodium tartrate tetrahydrate in deionized water, then adjust the pH value of the solution with sodium hydroxide to obtain 500ml of dark blue with a pH value of 12 Solution: Take 2ml of 38% formaldehyde solution with a pipet...

Embodiment 2

[0055] (1) Pre-soak the polyester thread with a 10 g / L tannic acid solution at room temperature for 40 minutes, take out the polyester thread, wash it with deionized water three times, and dry it to obtain a tannic acid-modified polyester thread.

[0056] (2) Soak the tannic acid-modified polyester thread in 100 g / L copper sulfate pentahydrate solution for 2 hours, take it out, and obtain the modified polyester thread that absorbs copper ions.

[0057] (3) The modified polyester thread adsorbed with copper ions was treated with 0.05 mol / L potassium borohydride solution for 120 s to obtain a polyester thread evenly attached to the metallic copper activation catalyst layer.

[0058] (4) Dissolve 1.0g copper sulfate pentahydrate, 0.6g nickel sulfate hexahydrate, and 12.5g potassium sodium tartrate tetrahydrate in deionized water, then adjust the pH value of the solution with sodium hydroxide to obtain 500ml of dark blue with a pH value of 12.5 solution. Use a pipette to take 3ml...

Embodiment 3

[0062] (1) Pre-soak the polyester thread with a 15 g / L tannic acid solution at room temperature for 30 minutes, take out the polyester thread, wash it with deionized water three times, and dry it to obtain a tannic acid-modified polyester thread.

[0063] (2) Soak the tannic acid modified polyester thread in 75 g / L copper sulfate pentahydrate solution for 3 hours, take it out, and obtain the modified polyester thread adsorbing copper ions.

[0064] (3) The modified polyester thread adsorbed with copper ions was treated with 0.1 mol / L sodium borohydride solution for 30 seconds to obtain a polyester thread evenly attached to the metallic copper activation catalyst layer.

[0065] (4) Dissolve 5.0g copper sulfate pentahydrate, 0.3g nickel sulfate hexahydrate, and 15.0g potassium sodium tartrate tetrahydrate in deionized water, then adjust the pH value of the solution with sodium hydroxide to obtain 500ml of dark blue with a pH value of 12.5 solution. Take 4ml of 38% formaldehyde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com