Super double-phase stainless steel composite steel plate and manufacturing method thereof

A duplex stainless steel and clad steel plate technology, applied in the direction of manufacturing tools, chemical instruments and methods, furnaces, etc., can solve the problems of reduced material toughness and corrosion resistance, and achieve good mechanical properties and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The chemical composition of base carbon steel is as follows (wt%): C: 0.045, Si: 0.20, Mn: 1.35, P: 0.015; S: 0.002, Al: 0.02, the composition of duplex stainless steel (wt%): C: 0.014, Si: 0.43, Mn: 1.27, Cr: 25.34, Ni: 7.32, Mo: 4.11, N: 0.30.

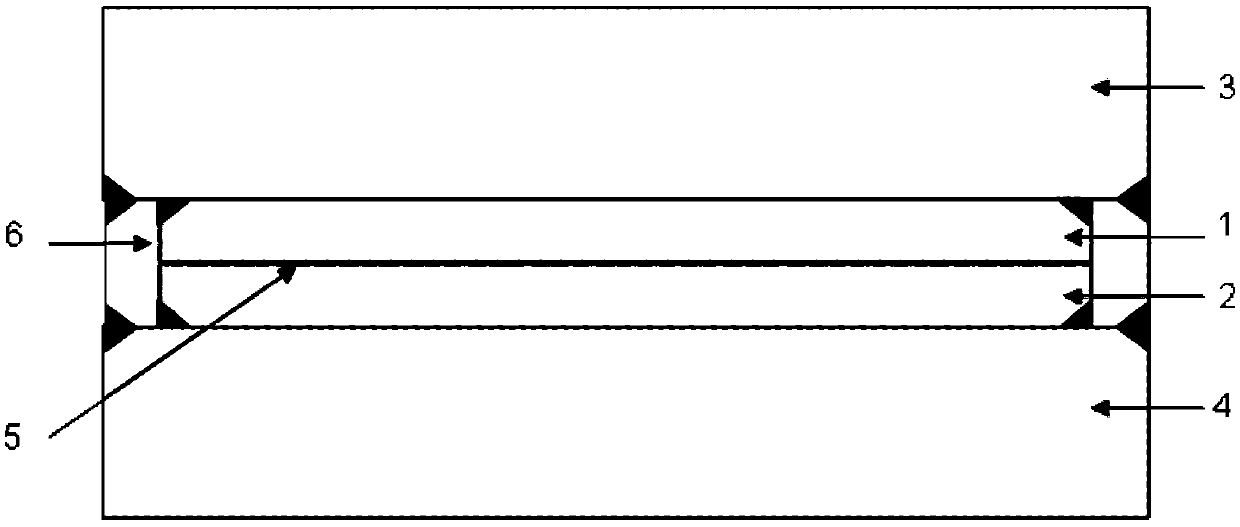

[0052] use as figure 1 The four-layer symmetrical separation method shown in the billet assembly: set up carbon steel billets, stainless steel billets, stainless steel billets and carbon steel billets in sequence from top to bottom, wherein the upper layer of carbon steel billets and their corresponding duplex stainless steel billets are vacuum-sealed, and the lower layer of carbon steel billets The corresponding duplex stainless steel billet is vacuum sealed to form two independent first vacuum systems; the second vacuum system consists of figure 1 Vacuum sealing is carried out between the first layer and the sixth layer (that is, the carbon steel billet and the carbon steel billet in this embodiment) shown. Together they f...

Embodiment 2

[0061] The base carbon steel adopts the grade carbon steel with a yield strength of 345MPa, and its chemical composition is (wt%): C: 0.12, Si: 0.24, Mn: 1.00, P: 0.015; S: 0.003, Nb: 0.01, Ti: 0.01, Al: 0.025, composition (wt%) of duplex stainless steel: C: 0.018, Si: 0.75, Mn: 1.25, Cr: 25.31, Ni: 7.19, Mo: 4.32, N: 0.30.

[0062] The way of assembling is the same as that of Example 1.

[0063] Composite rolling: Heating temperature is 1240°C, starting rolling temperature is 1200°C, finishing rolling temperature is 950°C; water spray cooling is used immediately after rolling, starting cooling temperature is 930°C, final cooling temperature is 670°C, rolling clad plate thickness is 3 +10mm, that is, the cladding stainless steel is 3mm thick, and the base carbon steel is 10mm thick.

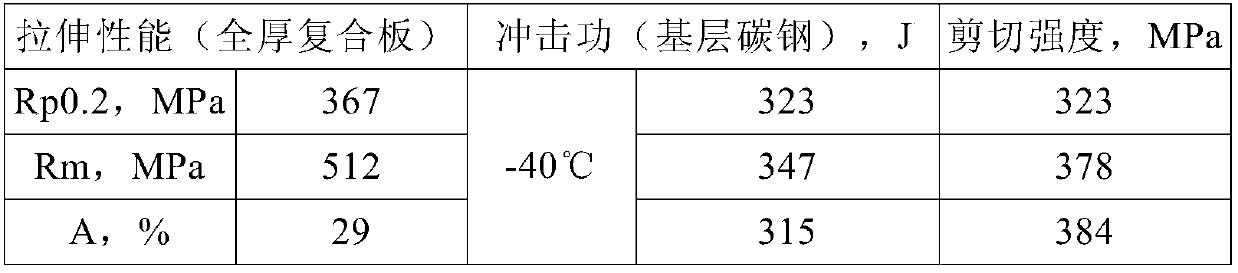

[0064] The mechanical properties of the rolled clad plates are shown in Table 3.

[0065] Table 3. Mechanical properties of (3+10)mm thick composite plate

[0066]

[0067]

[0068] *A 7...

Embodiment 3

[0073] The base carbon steel adopts the yield strength of 460MPa grade carbon steel, and its chemical composition is (wt%): C: 0.09, Si: 0.22, Mn: 1.20, P: 0.013; S: 0.002, Nb: 0.025, Ti: 0.012, dual phase Composition (wt%) of stainless steel: C: 0.016, Si: 0.40, Mn: 1.19, Cr: 25.71, Ni: 6.96, Mo: 4.23, N: 0.29.

[0074] The blank adopts the same four-layer symmetrical blank assembly method as in Example 1.

[0075] Composite rolling: heating temperature is 1150°C, starting rolling temperature is 1120°C, finishing rolling temperature is 930°C; after rolling, it is produced by water spray cooling, after cooling to 550°C, it is naturally cooled in the air. The thickness of the rolled clad plate is 2+8mm.

[0076] The mechanical properties of the rolled clad plates are shown in Table 5.

[0077] Table 5 (2+8)mm thick composite plate mechanical properties

[0078]

[0079] **Tested with a 7.5mm×10mm×55mm sample (the thickness of the base carbon steel is 7.5mm).

[0080] The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com