a cutting fluid

A cutting fluid and emulsifier technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of complicated preparation process and complex cutting fluid formulation components, and achieve good sterilization performance and improve corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

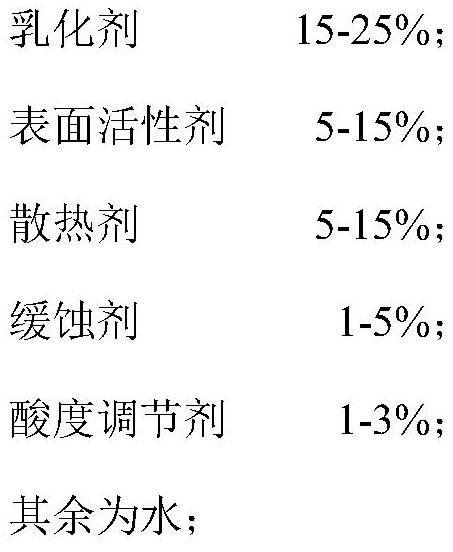

[0049] A kind of cutting fluid, by mass percentage, its raw material composition is shown in table 1.

[0050] Among them, urotropine is used as corrosion inhibitor; emulsifier OP-10 is used as emulsifier; DOWFAX2A1 is used as surfactant; ethylene glycol phenyl ether is used as cooling agent (and organic solvent); citric acid is used as acidity regulator.

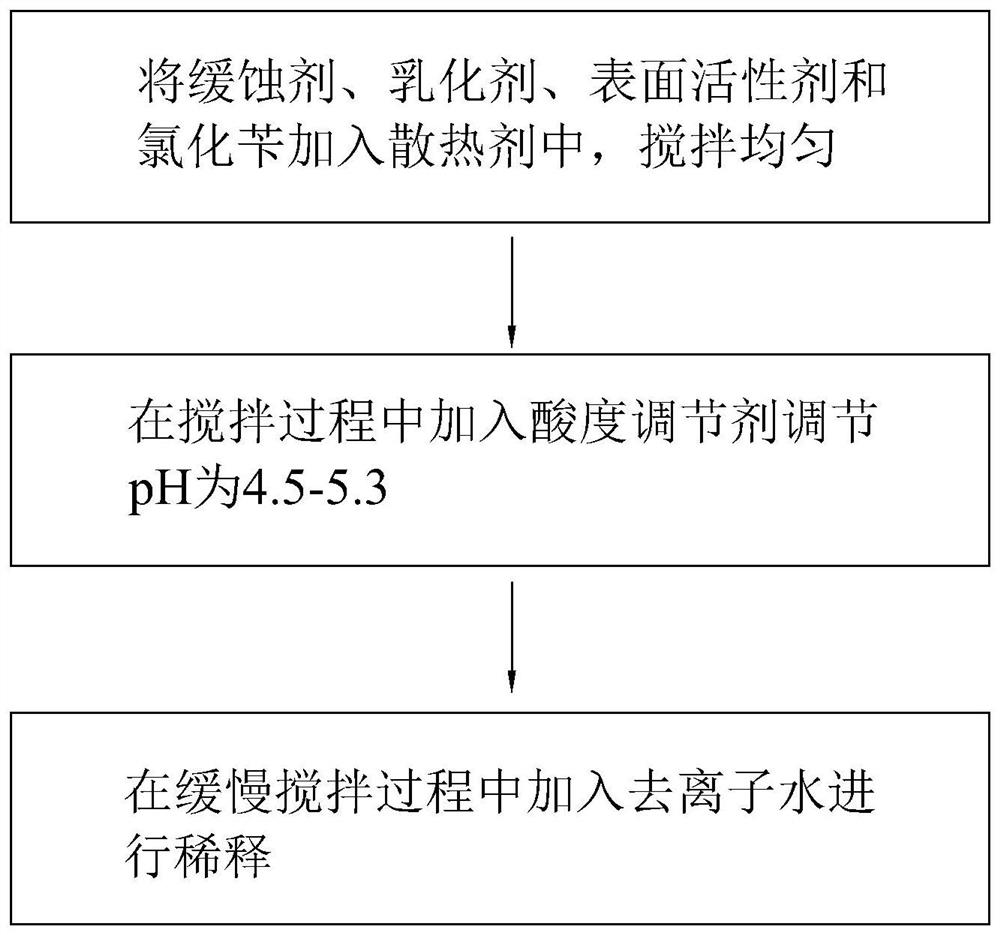

[0051] The preparation method of this cutting fluid comprises the following steps:

[0052] Step 1, adding corrosion inhibitor, emulsifier, surfactant and benzyl chloride into the cooling agent, stirring evenly;

[0053] Step 2, adding an acidity regulator during stirring to adjust the pH to 4.5-5.3;

[0054] Step 3, dilute by adding deionized water during slow stirring.

Embodiment 2

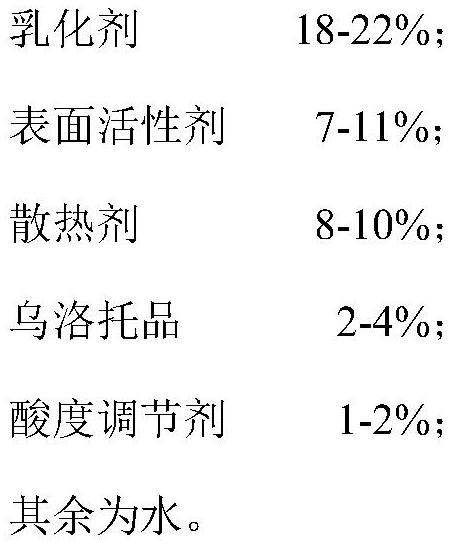

[0056] The difference from Example 1 is that, in terms of mass percentage, the cutting fluid raw material components are shown in Table 1.

Embodiment 3

[0058] The difference from Example 1 is that, in terms of mass percentage, the cutting fluid raw material components are shown in Table 1, and DOWFAX 2A1 is used to completely replace the emulsifier OP-10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com