Color asphalt composition capsule and preparation method thereof

A technology of colored asphalt and composition, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of polluting energy consumption, failure to solve the environment, etc., to reduce emissions, solve environmental pollution, service performance and service life improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

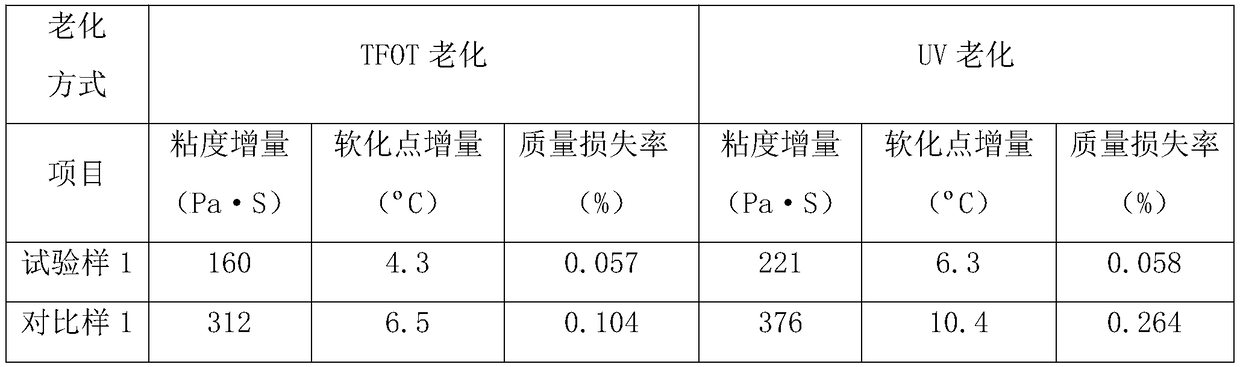

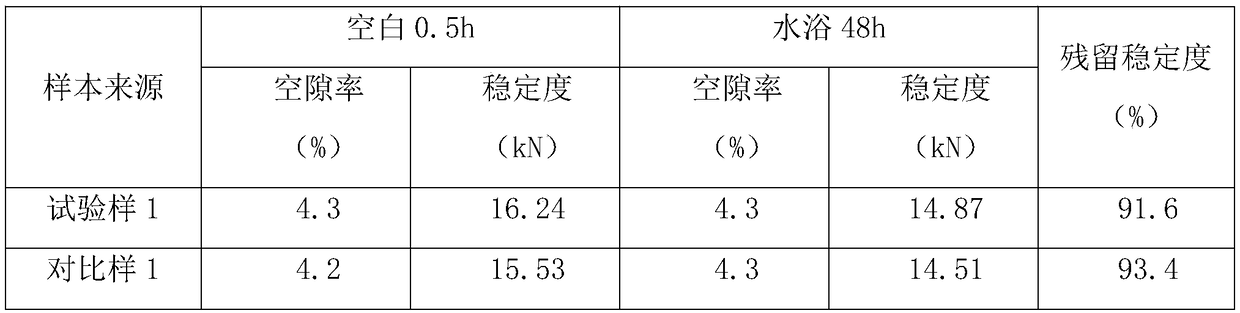

Embodiment 1

[0024] A colored asphalt composition capsule is prepared according to the following process steps:

[0025] 1) In terms of parts by mass, weigh 15 parts of inorganic pigments, 50 parts of decolorized pitch, 28.45 parts of slaked lime, 6 parts of organic montmorillonite modified by octadecyl trimethyl quaternary ammonium salt, 0.5 parts of zeolite, and 0.05 parts of water share;

[0026] 2) After heating the decolorized asphalt to a molten state, put it into a container, add inorganic pigments and organic montmorillonite at a temperature of 145°C, and then place it in a high-speed shearing instrument with a rotation speed of 5000r / min. Cut for 45 minutes to obtain the mixture A of "bleached asphalt-inorganic pigment-organic montmorillonite mixed system";

[0027] 3) After adding zeolite and water to the mixture A, place it on a high-speed mixer with a rotating speed of 800r / min, stir for 3min, and obtain the blending system of "decolorized asphalt-inorganic pigment-organic mon...

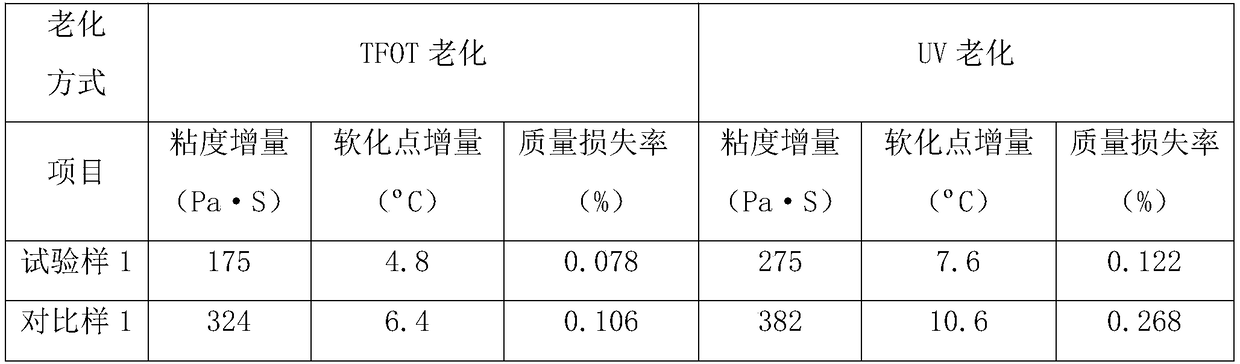

Embodiment 2

[0046] A colored asphalt composition capsule is prepared according to the following process steps:

[0047]1) In terms of parts by mass, weigh 10 parts of inorganic pigments, 60 parts of decolorized pitch, 25.45 parts of slaked lime, 4 parts of organic montmorillonite modified by octadecyl trimethyl quaternary ammonium salt, 0.5 parts of zeolite, and 0.05 parts of water. share;

[0048] 2) After heating the decolorized asphalt to a molten state, put it into a container, add inorganic pigments and organic montmorillonite at a temperature of 145°C, and then place it in a high-speed shearing instrument with a rotation speed of 5000r / min. Cut for 45 minutes to obtain the mixture A of "bleached asphalt-inorganic pigment-organic montmorillonite mixed system";

[0049] 3) After adding zeolite and water to the mixture A, place it on a high-speed mixer with a rotating speed of 800r / min, stir for 3min, and obtain the blending system of "decolorized asphalt-inorganic pigment-organic mon...

Embodiment 3

[0069] A colored asphalt composition capsule is prepared according to the following process steps:

[0070] 1) In terms of parts by mass, weigh 20 parts of inorganic pigments, 40 parts of decolorized pitch, 31.45 parts of slaked lime, 8 parts of organic montmorillonite modified by octadecyl trimethyl quaternary ammonium salt, 0.5 parts of zeolite, and 0.05 parts of water. share;

[0071] 2) After heating the decolorized asphalt to a molten state, put it into a container, add inorganic pigments and organic montmorillonite at a temperature of 145°C, and then place it in a high-speed shearing instrument with a rotation speed of 5000r / min. Cut for 45 minutes to obtain the mixture A of "bleached asphalt-inorganic pigment-organic montmorillonite mixed system";

[0072] 3) After adding zeolite and water to the mixture A, place it on a high-speed mixer with a rotating speed of 800r / min, stir for 3min, and obtain the blending system of "decolorized asphalt-inorganic pigment-organic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com