Thermally vulcanized chloroprene mortar and preparation method thereof

A technology of vulcanized neoprene mortar and vulcanized neoprene rubber, which is applied in the field of mortar, can solve problems such as easy burning, great harm to operators, and excessive loss of burning time, etc., and achieves long service life of bending resistance, Improve the performance of mixing operation and improve the effect of anti-thermal and oxidative aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

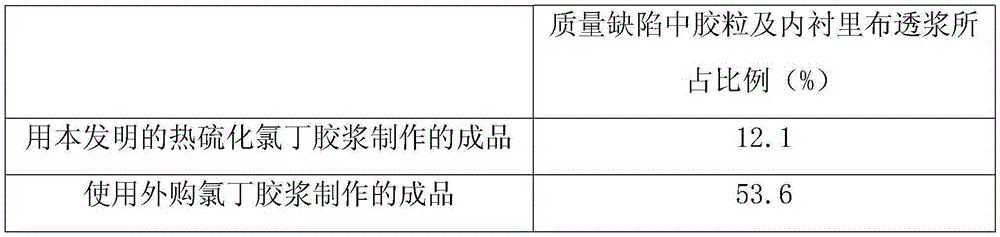

Examples

preparation example Construction

[0026] The present invention also discloses a preparation method of thermally vulcanized chloroprene mortar, comprising the following steps:

[0027] a. Masticating: add the domestic No. 1 tobacco rubber into the open mill according to the set weight, and carry out thin-pass plasticizing at a roller temperature of 40°C to 50°C until the Vickers plasticity is 0.30-0.38;

[0028] b. Mixing: Put the neoprene into the open mill with a roller temperature of 30°C to 40°C until the rubber is heated and pressed to soften, then widen the roller distance, put in the softened neoprene, and put into the plasticized The domestic No. 1 smoked rubber film is wrapped with a roll. After the rubber material is smooth and flat, light magnesium oxide, accelerator, anti-aging agent, white carbon black, and indirect method zinc oxide are mixed and prepared at a time according to the set weight. into film;

[0029] c. Glue preparation: before starting the mixer, add part of the mixed solvent as bas...

Embodiment 1

[0034] The thermally vulcanized neoprene mortar of the present embodiment, the mortar raw material comprises the following components by weight: 93 parts of neoprene, 8 parts of domestic smoked rubber No. 1, 0.9 part of accelerator, 5 parts of indirect zinc oxide, 7 parts of magnesium oxide, 1.5 parts of anti-aging agent, 0.1 part of anti-scorch agent, 9 parts of white carbon black, 5 parts of tackifier, and 193 parts of mixed solvent.

[0035] In this embodiment, the mixed solvent is a mixture of butyl acetate and 120# solvent oil, and the weight ratio of butyl acetate and 120# solvent oil is 3:2.

[0036] In this embodiment, the accelerator is accelerator NA-22.

[0037] In this embodiment, the anti-aging agent is a mixture of anti-aging agent 2246 and anti-aging agent SP-C, and the weight ratio of the anti-aging agent 2246 and anti-aging agent SP-C is 1:2.

[0038] In this embodiment, the anti-scorch agent is accelerator DM (2,2'-dithiodibenzothiazole), which is used for ant...

Embodiment 2

[0057] The thermally vulcanized neoprene mortar of this embodiment, the mortar raw material comprises the following components by weight: 95 parts of neoprene, 5 parts of domestic smoked rubber No. 1, 0.9 part of accelerator, 5 parts of indirect zinc oxide, light 8 parts of magnesium oxide, 1.5 parts of anti-aging agent, 0.2 parts of anti-scorch agent, 8 parts of white carbon black, 5 parts of tackifier, and 193.05 parts of mixed solvent.

[0058] In this embodiment, the mixed solvent is a mixture of butyl acetate and 120# solvent oil, and the weight ratio of butyl acetate and 120# solvent oil is 3:2.

[0059] In this embodiment, the accelerator is accelerator NA-22.

[0060] In this embodiment, the anti-aging agent is a mixture of anti-aging agent 2246 and anti-aging agent SP-C, and the weight ratio of the anti-aging agent 2246 and anti-aging agent SP-C is preferably 1:2.

[0061] In this embodiment, the anti-scorch agent is accelerator DM (2,2'-dithiodibenzothiazole), which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com