PC/PCTG alloy as well as preparation method and application thereof

An alloy and polysiloxane technology, which is applied in the field of PC/PCTG alloy and its preparation, can solve the problems of easy smearing of the ink layer and low yield of plastic parts, so as to improve the anti-thermal oxidation aging effect and anti-thermal oxygen aging effect. The effect of improving the function and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

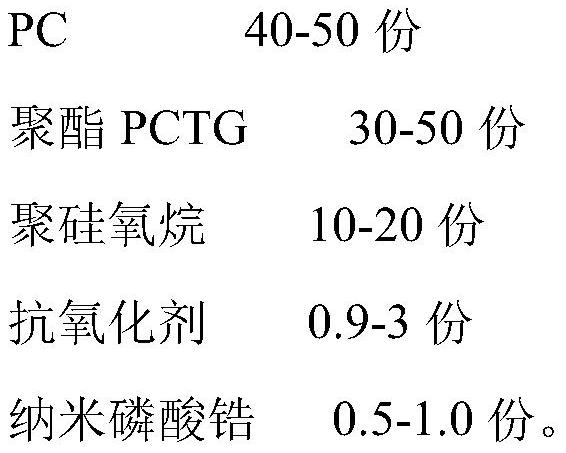

Method used

Image

Examples

Embodiment 1

[0043] A kind of PC / PCTG alloy is made by following steps:

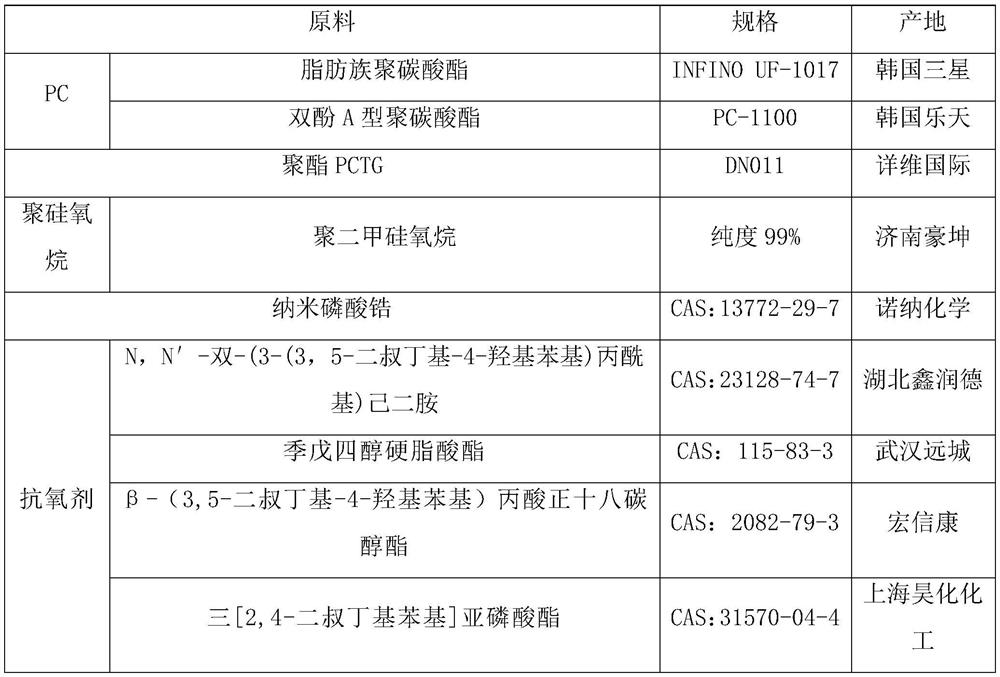

[0044] S1. Weigh 40g of INFINO UF-1017, 30g of DN011, 10g of polydimethylsiloxane (number-average molecular weight of 1800), 0.9g of N,N′-bis-(3-(3,5-di-tert-butyl-4 -Hydroxyphenyl) propionyl) hexamethylenediamine and 0.5g nanometer zirconium phosphate (average particle diameter is 150nm) drop in high-speed mixer and carry out stirring and blending, and stirring speed is 7200r / h, carry out premixing, obtain mixture;

[0045] S2. Put the mixture obtained in step 1 into a parallel twin-screw extruder to melt and extrude. The temperature settings of each zone of the screw in the extruder are respectively: the temperature of the first zone is 230°C, the temperature of the second zone is 230°C, and the temperature of the third zone is 245°C , the temperature in the fourth zone is 250°C, the temperature in the fifth zone is 250°C, the temperature in the sixth zone is 250°C, the temperature in the seventh zone is 250°C, the...

Embodiment 2

[0047] A PC / PCTG alloy, made on the basis of Example 1, differs from Example 1 in that: 40g of aliphatic polycarbonate INFINO UF-1017 is replaced by bisphenol A polycarbonate PC- 1100.

Embodiment 3-10

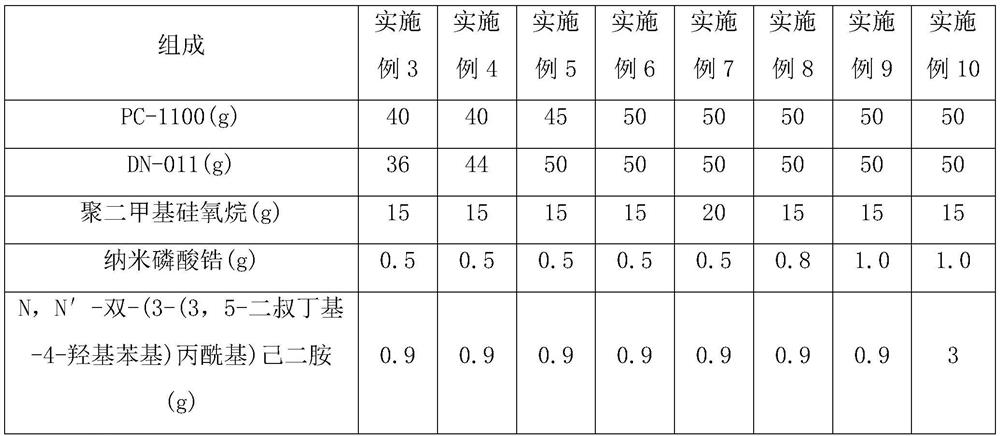

[0049]A PC / PCTG alloy, prepared on the basis of Example 2, differs from Example 1 in that the composition of the PC / PCTG alloy is different, and the specific composition is shown in Table 2 below.

[0050] Table 2. Composition of PC / PCTG alloys

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com