Polyepoxypropylhexylguanidine hydrochloride and preparation method thereof

The technology of polyglycidyl hexylguanidine hydrochloride and guanidine hydrochloride is applied in the field of plastic antibacterial agents, and can solve the problems of delayed effect of silver-based antibacterial agents, easy discoloration of mammalian cytotoxicity, and PET plastic wire drawing process. Can not be carried out, affect the structure and performance of PET, etc., to achieve the effect of excellent sterilization effect, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

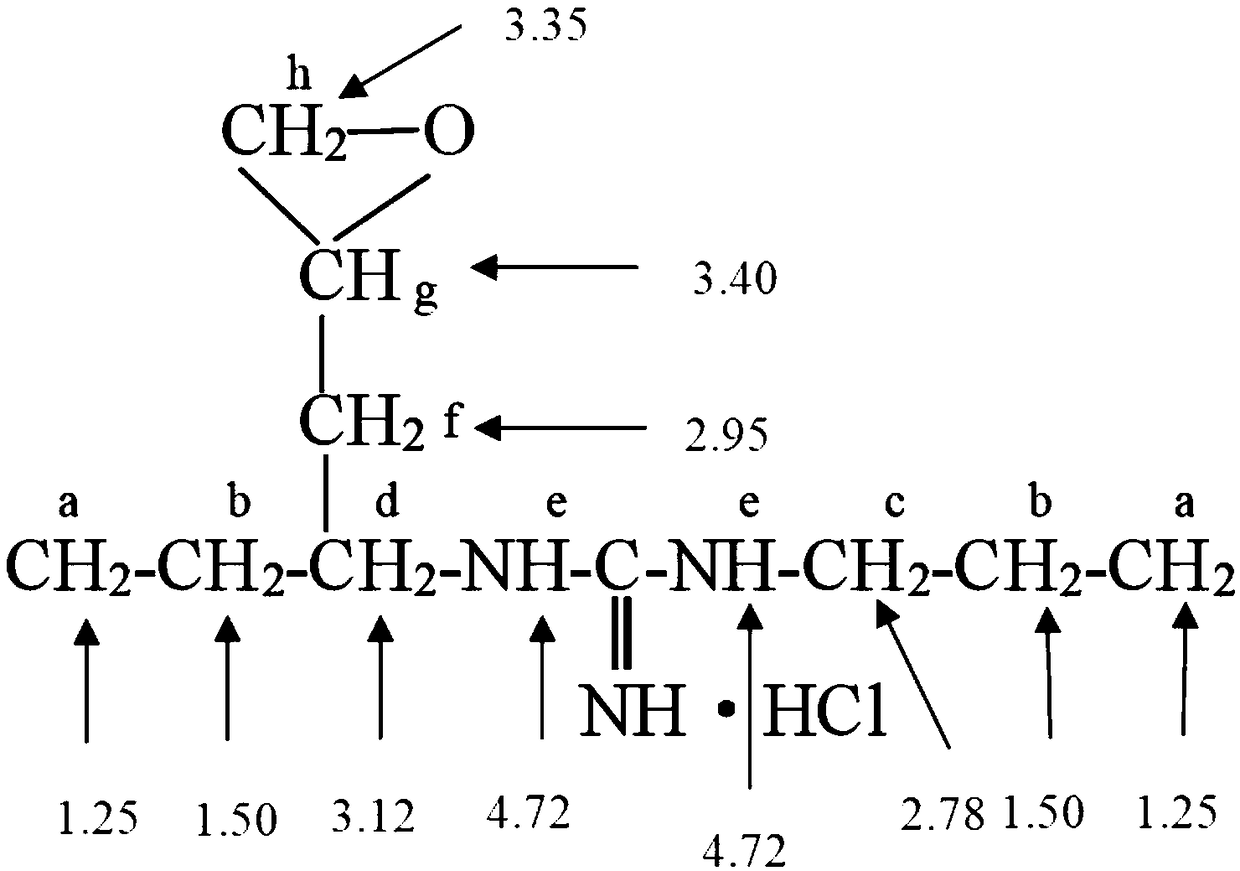

[0031] Embodiment 1: the preparation of polyglycidyl hexylguanidine hydrochloride solid a

[0032] S1: Keep the 500L reactor stirring at a constant speed, add 100.00kg of guanidine hydrochloride, 121.70kg of 1,6-hexamethylenediamine, and 0.30kg of malondialdehyde as an initiator in sequence. Stir the reaction at 5°C for 45 minutes, stir the reaction at 120±5°C for 80 minutes, and stir the reaction at 140±5°C for 90 minutes;

[0033] S2: Maintain the reaction temperature at 140±5°C, and add 60.80 kg of propylene oxide at a constant speed within 15 minutes, and then continue to stir for 20 minutes;

[0034] S3: Add 0.32 kg of stopper propylene glycol into the reactor, stop heating, continue to stir for 10 minutes, and then the reaction ends to obtain a polymer melt;

[0035] S4: Transfer the polymer melt in the reaction kettle to a hydrolysis tank, add 350kg of pure water for hydrolysis, and obtain an aqueous solution of polyglycidyl hexylguanidine hydrochloride crude product w...

Embodiment 2

[0038] Embodiment 2: the preparation of polyglycidyl hexylguanidine hydrochloride solid b

[0039]S1: Keep the 1000L reactor stirring at a constant speed, add 250.00kg of guanidine hydrochloride, 304.10kg of 1,6-hexamethylenediamine, and 0.90kg of the initiator succinic dialdehyde in sequence. Stir the reaction at 5°C for 70 minutes, stir the reaction at 120±5°C for 110 minutes, and stir the reaction at 140±5°C for 120 minutes;

[0040] S2: Maintain the reaction temperature at 140±5°C, and add 152.00 kg of propylene oxide at a constant speed within 25 minutes, and then continue to stir for 30 minutes;

[0041] S3: Add 0.94 kg of stopper butanediol into the reactor, stop heating, continue to stir for 20 minutes, and then the reaction ends to obtain a polymer melt;

[0042] S4: Transfer the polymer melt in the reaction kettle to a hydrolysis tank, add 1500kg of pure water for hydrolysis, and obtain an aqueous solution of polyglycidyl hexylguanidine hydrochloride crude product w...

Embodiment 3

[0044] Embodiment 3: the preparation of test sample

[0045] 1. The preparation of polyglycidyl hexylguanidine hydrochloride 0.5% (w / w) aqueous solution sample: get 5.00g polyglycidyl hexylguanidine hydrochloride solid a, dilute to 0.5% (w / w) with 995.00g pure water / w) aqueous solution, numbered as 1# sample.

[0046] ②Preparation of antibacterial plastic samples with 0.5% (w / w) polyglycidyl hexylguanidine hydrochloride powder added: take 150.0 g of polyglycidyl hexylguanidine hydrochloride solid a, and grind it into powder. Get 30.0g polyglycidyl hexyl guanidine hydrochloride powder, in the blow molding process in plastics production, 30.0g polyglycidyl hexyl guanidine hydrochloride powder is evenly added in the plastics of 5970g, keep temperature at Above 160°C for 10 minutes to make it fully react to produce antibacterial plastics. According to different plastic materials, according to this method, 6000g of antibacterial plastics made of PP, PE, PET, PVC, and PS were res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com