Preparation method of glass with functions of absorbing ultraviolet and infrared rays and preventing glaring

A technology for absorbing ultraviolet and functional glass, applied in the field of glass technology application, can solve the problems of adverse environmental impact, difficult molding process, poor heat absorption performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

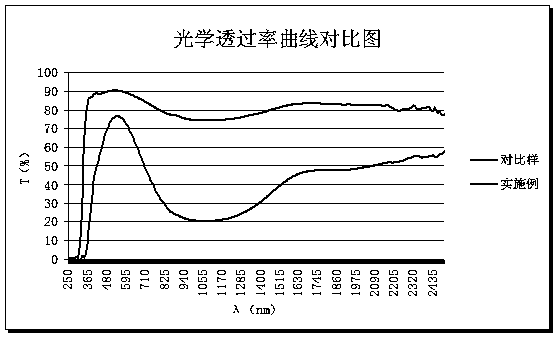

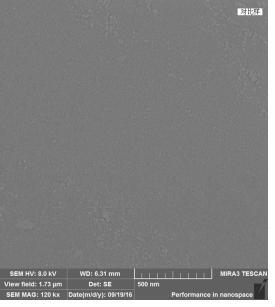

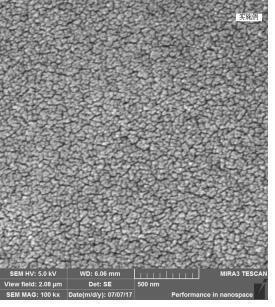

[0022] In order to better understand the present invention, the present invention will be described in more detail through the following examples, but the present invention is not limited to the following examples; the ingredients of the examples are formulated according to Table 1.

[0023] Table 1 comparative sample and embodiment composition content and material recipe table

[0024]

[0025] According to the high-temperature melting scheme 1 in the above table, introduce the above basic components through ultra-white silica sand, dolomite, limestone, soda ash, alumina, Glauber's salt, etc., of which Glauber's salt is used as a melting clarifier with a purity of more than 99.5%. Mix well, put it into a quartz crucible, place it in a high-temperature furnace and heat it to 1500°C, and keep it warm for 2 hours. Cast the molten glass onto a preheated graphite plate and place it in a holding furnace at 600°C for annealing. After rough grinding and polishing, a sample with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com